Operation arc master 175 te – Tweco 175 TE Arcmaster User Manual

Page 31

oPeration

arc master 175 te

Manual 0- 5116 4-3

Operation

a. Power on indicator

The Power ON Indicator illuminates when the ON/OFF

switch is in the ON position and the correct mains

voltage is present.

B. over Heat indicator

The welding power source is protected by a self

resetting thermostat. The indicator will illuminate if the

duty cycle of the power source has been exceeded. If

the Over Heat light illuminates wait for the Over Heat

light to extinguish before resuming welding.

c. trigger mode selection switch (tiG mode only)

normal mode

Press the TIG Torch Trigger Switch and hold depressed

to weld. Release the TIG Torch Trigger Switch to stop

welding. Downslope operates in TIG mode only. Whilst

welding if the TIG Torch Trigger Switch is released, the

welding current ramps down to zero current over a

defined period of time. The time period is determined

by the Downslope Control Knob (F).

Latch mode

This mode of welding is mainly used for long weld

runs. The operator need only to press the TIG Torch

Trigger Switch to activate and then release the TIG

Torch Trigger Switch to continue to weld, then press

the TIG Torch Trigger Switch again and release the TIG

Torch Trigger Switch to stop welding. This eliminates

the need for the operator to depress the TIG Torch

Trigger Switch for the complete length of the weld.

Downslope operates in TIG Mode only. To activate the

Downslope function in Latch mode whilst welding, the

TIG Torch Trigger Switch must be depressed and held

which will ramp the Welding Current down to zero over

a defined period of time. The time period is determined

by the Downslope Control Knob (F). At any time whilst

welding if the TIG Torch Trigger Switch is depressed

and released the arc will extinguish immediately.

D. Process selection switch

Switches between Manual Arc, Lift TIG and HF TIG

modes. Refer to Section 3.08 Setup for Manual Arc

Welding and 3.09 Setup for TIG Welding.

e. Welding current control

The welding current is increased by turning the Weld

Current Control Knob clockwise or decreased by

turning the Weld Current Control Knob anticlockwise.

The welding current should be set according to the

specific application. Refer to application notes in this

section for further information.

f. arc force/Down slope control

Arc Force is effective when in Manual Arc Mode only.

Arc Force control provides an adjustable amount of

Arc Force (or “dig”) control. This feature can be

particularly beneficial in providing the operator the

ability to compensate for variability in joint fit-up

in certain situations with particular electrodes. In

general increasing the Arc Force control toward ‘10’

(maximum Arc Force) allows greater penetration

control to be achieved. Down Slope operates in TIG

mode only. It is used to set the time for weld current

to ramp down. Refer to Item C (Trigger Mode Selection

Switch) for further information regarding Downslope

operation.

G. Gas outlet

The Gas Outlet is a 5/8-18 UNF female gas fitting and is

utilised for the connection of a suitable TIG Torch.

H. Post Gas flow

Post Gas Flow is the time Gas flows after the arc

has extinguished. This is used to cool and reduce

oxidisation of the Tungsten Electrode. Post Gas Flow

time is proportional to the Welding Current. For

example if the Welding Current is set to 10 amps the

Post Gas Flow time will be approximately 3 +0/-1

seconds. For a Welding Current set to 175 Amps the

Post Gas Flow time will be approximately 6 +1/-0

seconds. The Post Gas Flow time cannot be adjusted

independently of the Welding Current.

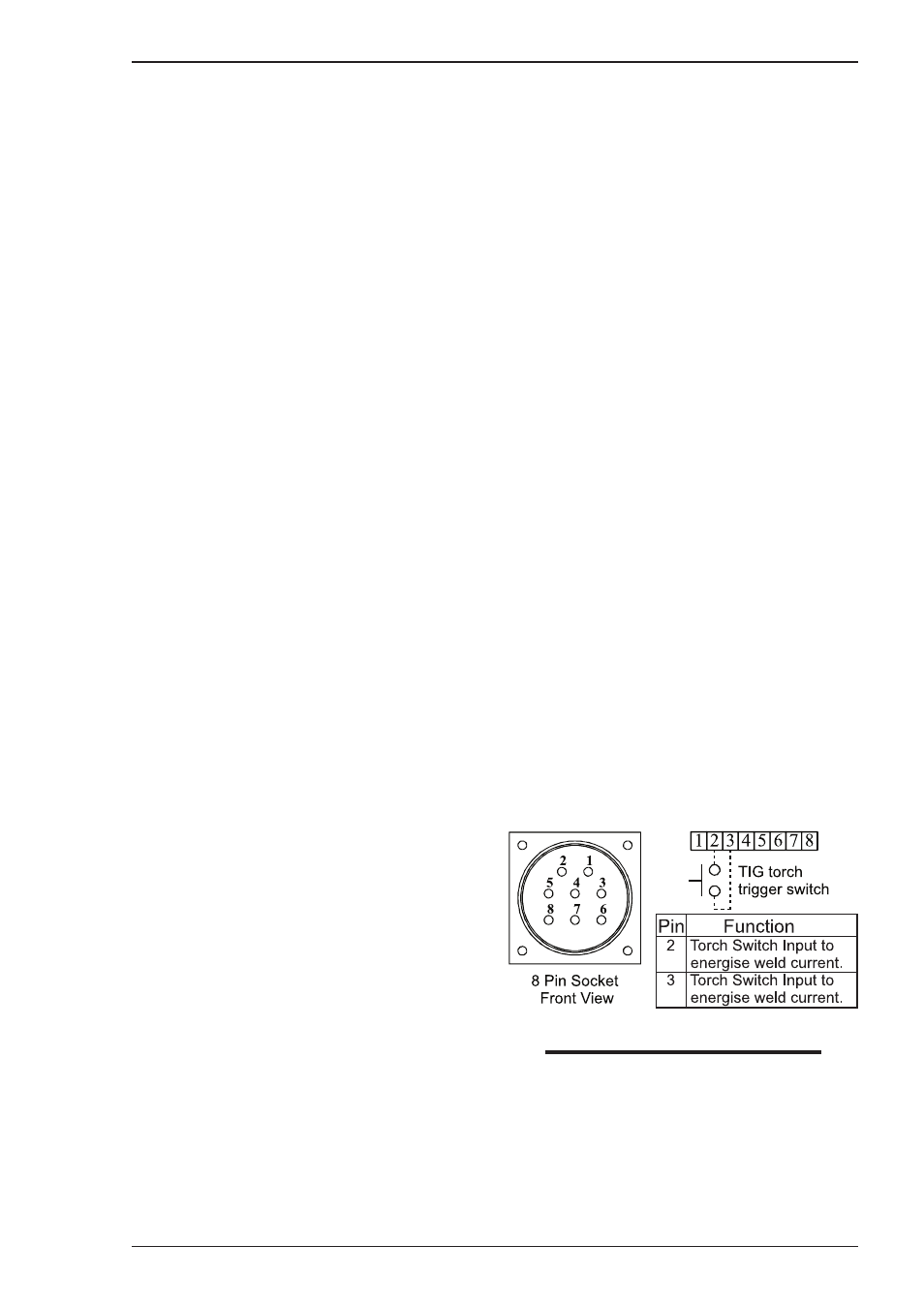

i. torch trigger socket

The 8 pin Torch Trigger Socket is used to connect the

TIG Torch Trigger Switch to the welding Power Source.

To make connections, align keyway, insert plug, and

rotate threaded collar fully clockwise.

Art # A-08956

NOTE:

Remote Welding Current Control is not available

on this model.

J. on/off switch (located on rear panel not

shown)

This switch controls the Mains Supply Voltage to the

Power Source.