Arcmaster, 160 s – Tweco 160 S Arcmaster User Manual

Page 31

ARCMASTER

®

160 S

March 31, 2006

7-1

SECTION 7:

BASIC TIG WELDING GUIDE

7.01 Electrode Polarity

Connect the TIG torch to the - / TORCH terminal and the work lead to the + / WORK terminal for direct current straight polarity.

Direct current straight polarity is the most widely used polarity for DC TIG welding. It allows limited wear of the electrode since

70% of the heat is concentrated at the work piece.

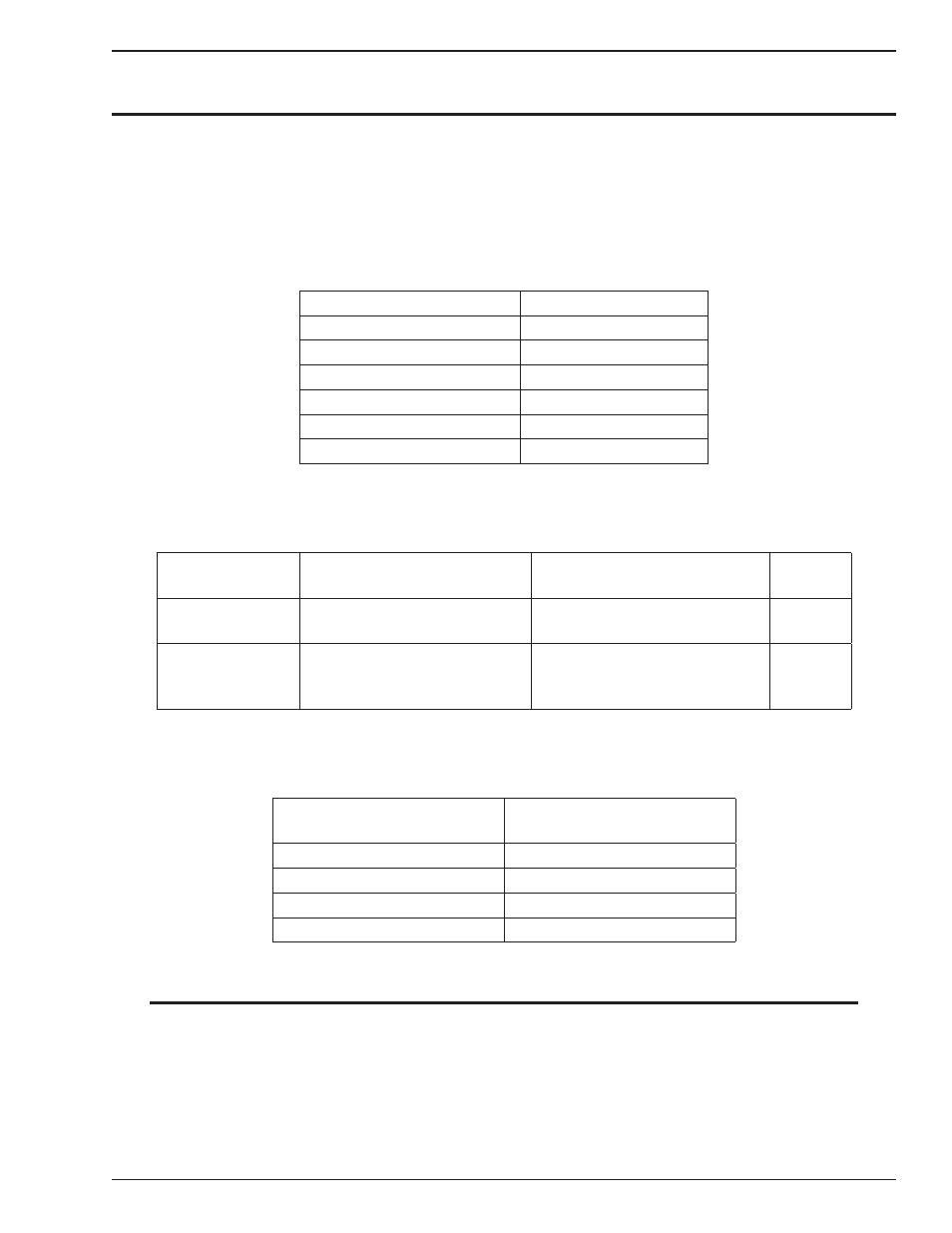

7.02 Tungsten Electrode Current Ranges

Electrode Diameter

DC Current (Amps)

0.040” (1.0mm)

30 – 60

1/16” (1.6mm)

60 – 115

3/32” (2.4mm)

100 – 165

1/8” (3.2mm)

135 – 200

5/32” (4.0mm)

190 – 280

3/16” (4.8mm)

250 – 340

Table 4 – Current ranges for varies tungsten electrode sizes

7.03 Tungsten Electrode Types

Electrode Type

(Ground Finish)

Welding Application

Features

Color

Code

Thoriated 2%

DC welding of mild steel, stainless

steel and copper.

Excellent arc starting, Long life, High

current carrying capacity.

Red

Ceriated 2%

DC welding of mild steel, stainless

steel, copper, aluminium,

magnesium and their alloys

Longer life, More stable arc, Easier

starting, Wider current range,

Narrower more concentrated arc.

Grey

Table 5 – Tungsten electrode types

7.04 Guide for Selecting Filler Wire Diameter

Filler Wire Diameter

DC Current Range

(Amps)

1/16” (1.6 mm)

20 - 90

3/32” (2.4 mm)

65 - 115

1/8” (3.2 mm)

100 - 165

3/16” (4.8 mm)

200 - 350

Table 6 – Filler wire selection guide

NOTE

The fi ller wire diameter specifi ed in Table 9 is a guide only, other diameter wires may be used according to the

welding application.