Arcmaster, 160 s – Tweco 160 S Arcmaster User Manual

Page 20

ARCMASTER

®

160 S

March 31, 2006

3-2

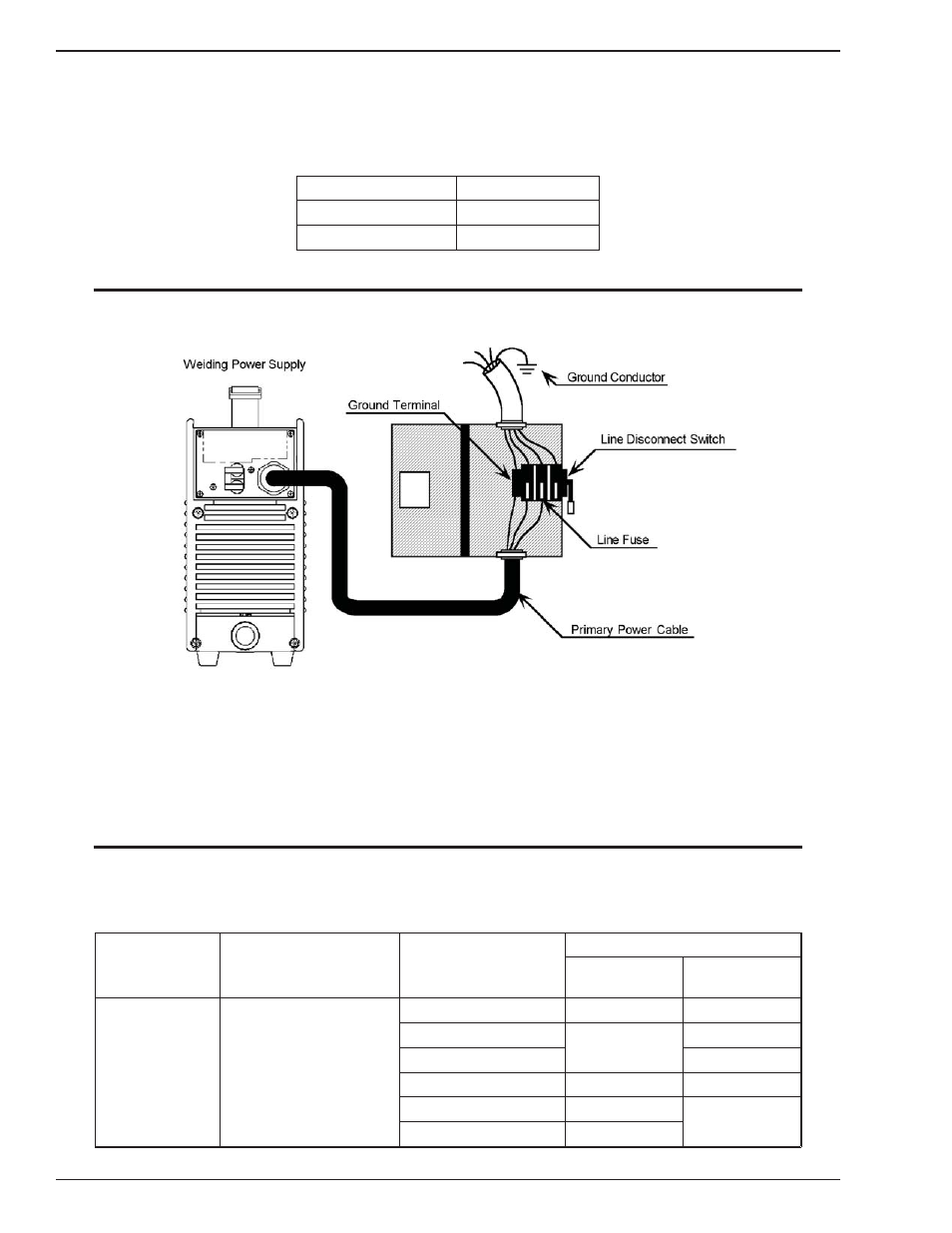

Refer to fi gure 3 and:

1. Connect end of ground (GREEN) conductor to a suitable ground. Use a grounding method that complies with all applicable

electrical codes.

2. Connect ends of line 1 (BLACK) and line 2 (WHITE) input conductors to a de-energized line disconnect switch.

3. Use Table 1 and Table 2 as a guide to select line fuses for the disconnect switch.

Input Voltage

Fuse Size

115 V

40 Amps

208-230 V

45 Amps

Table 1 - Electrical Input Connections

NOTE

Fuse size is based on not more than 200 percent of the rated input amperage of the welding power source (Based

on Article 630, National Electrical Code).

Figure 3 - Electrical Input Connections

• Input Power

Each unit incorporates an INRUSH circuit and input voltage sensing circuit. When the MAIN CIRCUIT SWITCH is turned on, the

inrush circuit provides a pre-charging of the input capacitors. SCR’s in the Power Control Assembly (PCA) will turn on after the

input capacitors have charged to full operating voltage (after approximately 5 seconds).

NOTE

Note the available input power. Damage to the PCA could occur if 460VAC or higher is applied.

The following 115/208-230V Primary Current recommendations are required to obtain the maximum welding current and duty

cycle from this welding equipment:

Model

Primary Supply Lead Size

(Factory Fitted)

Minimum Primary

Current Circuit Size

(Vin/Amps)

Current & Duty Cycle

TIG

STICK

ArcMaster 160 S

12/3 AWG minimum

115/23

85A @ 100%

-

208/28

160A @ 35%

-

230/25

-

115/40

-

85A @ 100%

208/44

-

160A @ 35%

230/39

-

Table 2 – 115/208-230V Primary Current Circuit sizes to achieve maximum current