Tweco Tri-Arc Serie User Manual

Page 22

5-2

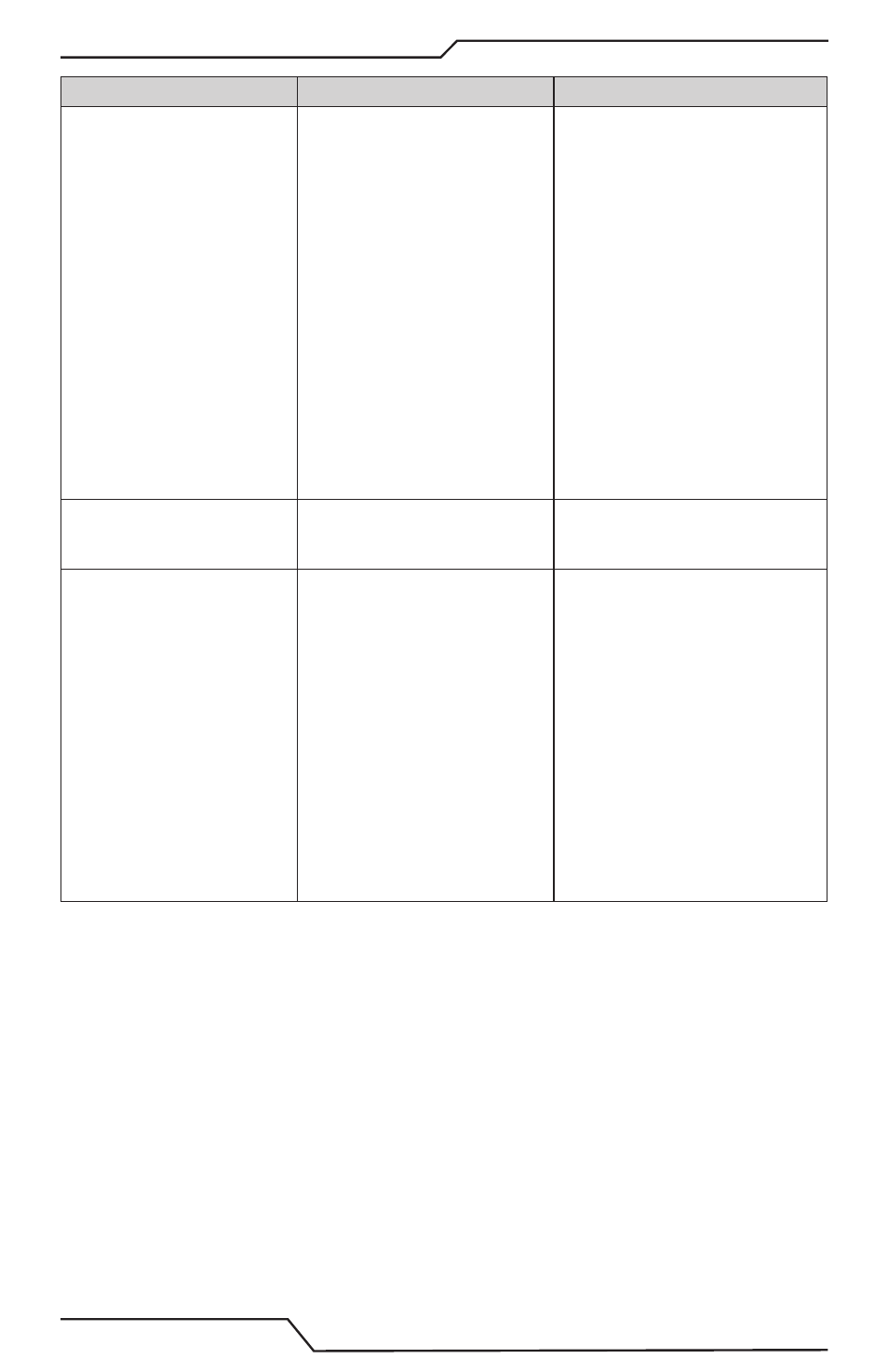

Problem

Cause

Solution

In gouging, free carbon

deposits at varying

groove intervals; in pad

-washing, free carbon

deposits at various spots

on the washed surface.

1. A shorted electrode

on the workpiece. In

manual gouging, this

is a result of excessive

travel speed for the

amperage used and for

the depth of the groove

being made. In mecha-

nized operations, this

is a result of excessive

travel speed or using

a flat-curve, constant-

voltage power source

for a small diameter

electrode 5/16" (7,9

mm). In padwashing,

this is caused by hold-

ing the electrode at too

small a push angle.

1. Use an electrode-to-work

angle of 15° to 70°. A

smaller angle increases

the arcing area,reducing

the current density; this

reduction in arc-current

density requires a great

decrease in arc length, to

the point of short circuit.

Keep a proper arc gap.

Irregular groove: too

deep, then too shallow.

1. The operator was

unsteady.

1. The operator should

assume a comfortable

position while gouging.

Slag adhering to the

edges of the groove.

1. Slag ejection was

inadequate. To resolve,

keep a proper air

pressure and flow rate

(cfm). Air pressure be-

tween 80 and 100 psi

(550-690 kPa) may not

effectively eject all of

the slag if the volume

is insufficient.

1. To deliver adequate

volume, the air hose

feeding the concentric

cable assembly needs

a minimum hose ID of

3/8" (9.5 mm) for manual

torches. For automatic

torches, the minimum

hose ID should be 1/2"

(12.7 mm). Direct the air

jet parallel to the gouge

area. Do not favor one

side unless operator

wants to minimize slag

from adhering to one

side of the cut.