Tweco Tri-Arc Serie User Manual

Page 20

4-6

5. Hold the electrode as shown in Figure 4-18, so that a maximum of 7” (178 mm)

extends from the torch. This extension should be 3” (76.5 mm) for aluminum.

6. While the torch valve is open, adjust the air pressure at the torch to the normal

pres-

sures range between 80 psi (551.6 kPa) and 100 psi (690 kPa); higher pressures

may be used, but they do not remove metal more efficiently.

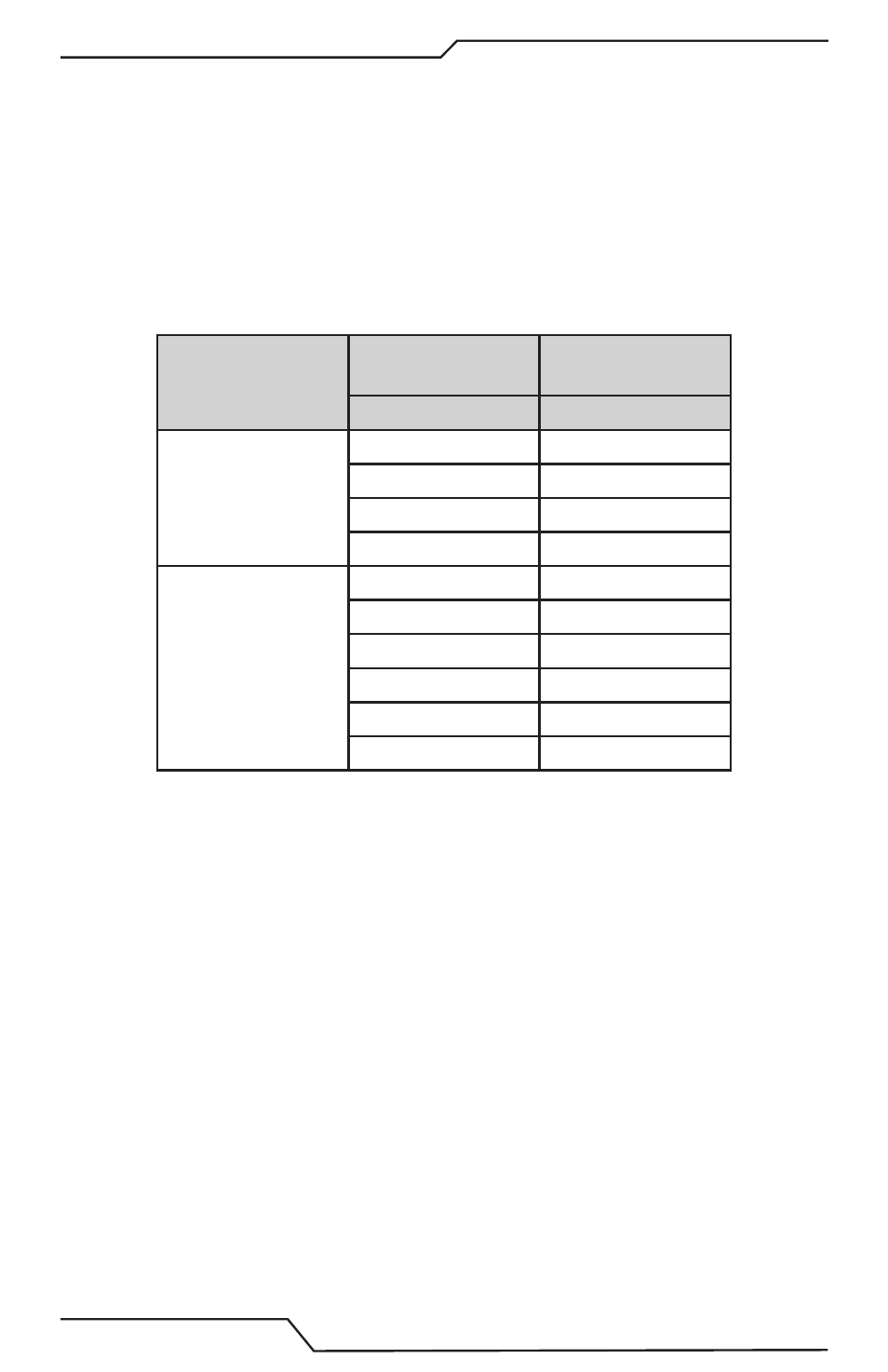

7. Adjust the welding current (Constant Current) or voltage (Constant Voltage), depend-

ing on the type of power supply being used, to the suggested current range shown

for the carbon diameter being used. Refer to Table 4-2.

Torch

Electrode

Diameter

DC Electrode DCEP

in (mm)

min - max

K-5

5/16 (7.9)

350 - 450

3/8 (9.5)

450 - 600

1/2 (12.7)

800 - 1000

5/8 (15.9)

1000 - 1250

Tri-Arc

®

Series

5/16 (7.9)

350 - 450

3/8 (9.5)

450 - 600

1/2 (12.7)

800 - 1000

5/8 (15.9)

1000 - 1250

3/4 (19.1)

1250 - 1600

1 (25.4)

1600 - 2200

Table 4-2: Suggested Current Ranges (AMP) for Commonly Used Electrode Types and Sizes

8. Turn on the air jet before striking the arc. Hold the torch between a 45˚ - 60˚ work

angle, so that the electrode slopes back from the direction of travel. The air jet sweeps

between the electrode and workpiece, providing the force to remove all molten metal

from the groove.

9. Lightly touch the electrode to the workpiece to establish the arc. Do not draw back the

electrode once the arc is ignited. When the correct arc voltage is being maintained,

the sound of the arc and the compressed air is loud. When the sound is muffled,

the arc voltage is below the recommended operating conditions. Normal arc voltage

with a handheld gouging torch is measured between 35 to 50 volts.

10. The groove’s depth is controlled by travel speed. Grooves up to 1” (25 mm) deep may

be made. However, the deeper the groove, the more experienced the operator needs to

be. Slow travel speeds produce deep grooves, and fast travel speeds produce shallow

grooves. The width of the groove is determined by the size of the electrode used and

is typically about 1/8” (3.2 mm) wider than the electrode’s diameter. A wider groove

may be made with a small electrode by oscillating in a circular or weave motion.