Stainless steel, 100a, N2 plasma / h20 secondary – Tweco XTTM-301 User Manual

Page 83

Manual 0-4768

A-9

APPENDIX

NOTE

Ohmic sensing is not recommended with water shield. Water on the

plate interferes electrically with the ohmic sensing system.

Stainless Steel

100A

N2 Plasma / H20 Secondary

Shield

(H2O)

(ga)

(in)

(in)

Ball

psi

Ball*

(volts)

(in)±0.00

5

(ipm)

(in)

(sec)

10

0.141

45

90

5

160

0.188

160

0.300

0.3

3/16

0.188

45

90

5

167

0.188

100

0.300

0.3

1/4

0.250

45

90

5

166

0.188

60

0.300

0.5

3/8

0.375

45

90

5

169

0.188

50

0.300

0.5

1/2

0.500

45

90

5

181

0.188

35

0.300

0.6

5/8

0.625

45

90

5

180

0.188

30

0.350

0.7

Shield

(H2O)

Ball

bar

Ball*

(volts)

(mm)

±0.125

(mm/min)

(mm)

(sec)

45

6.2

5

162

4.8

3530

7.6

0.3

45

6.2

5

167

4.8

2400

7.6

0.4

45

6.2

5

166

4.8

1750

7.6

0.5

45

6.2

5

168

4.8

1390

7.6

0.5

45

6.2

5

171

4.8

1210

7.6

0.5

45

6.2

5

178

4.8

970

7.6

0.6

45

6.2

5

180

4.8

800

8.9

0.7

* Ball setting for shield water is set using a line pressure of 55 PSI / 3.8 Bar

Bold type indicates maximum piercing parameters.

6

5

4

100A SS (N2/H2O)

Cut Flow Rates / Pressures

Plasma (N2)

Cut Flow Rates / Pressures

Plasma (N2)

Initial

Piercing

Height

Pierce

Delay

15

12

10

8

Pierce

Delay

Travel

Speed

Material

Thickness

** Arc

Voltage

Torch

Working

Height

Travel

Speed

Material

Thickness

(mm)

** Arc

Voltage

Torch

Working

Height

Initial

Piercing

Height

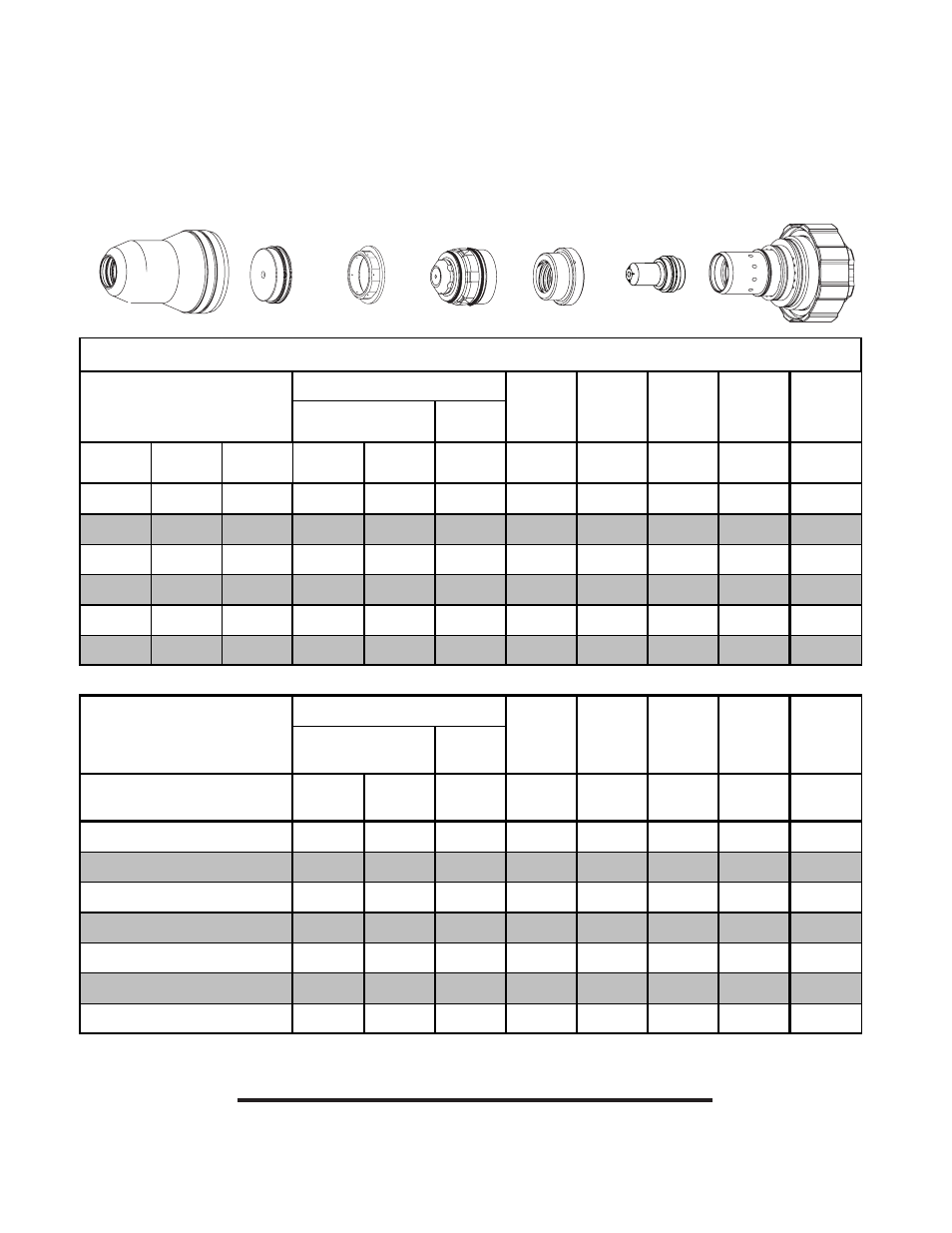

Art # A-06747

Shield Cap

35-1053

35-1089

35-1041

Cartridge

Shield Cup

35-1016

Plasma Gas Distributor

Shield Gas Distributor

35-1020

35-1034

35-1272

Tip

Electrode