08 machine torch operation – Tweco SL100 User Manual

Page 31

Manual 0-2962

4-7

OPERATION

7. Clean spatter and scale from the shield cup and the

tip as soon as possible. Spraying the shield cup in

anti - spatter compound will minimize the amount

of scale which adheres to it.

4.08 Machine Torch Operation

A. Cutting With Machine Torch

The machine torch can be activated by remote control

pendant or by a remote interface device such as CNC.

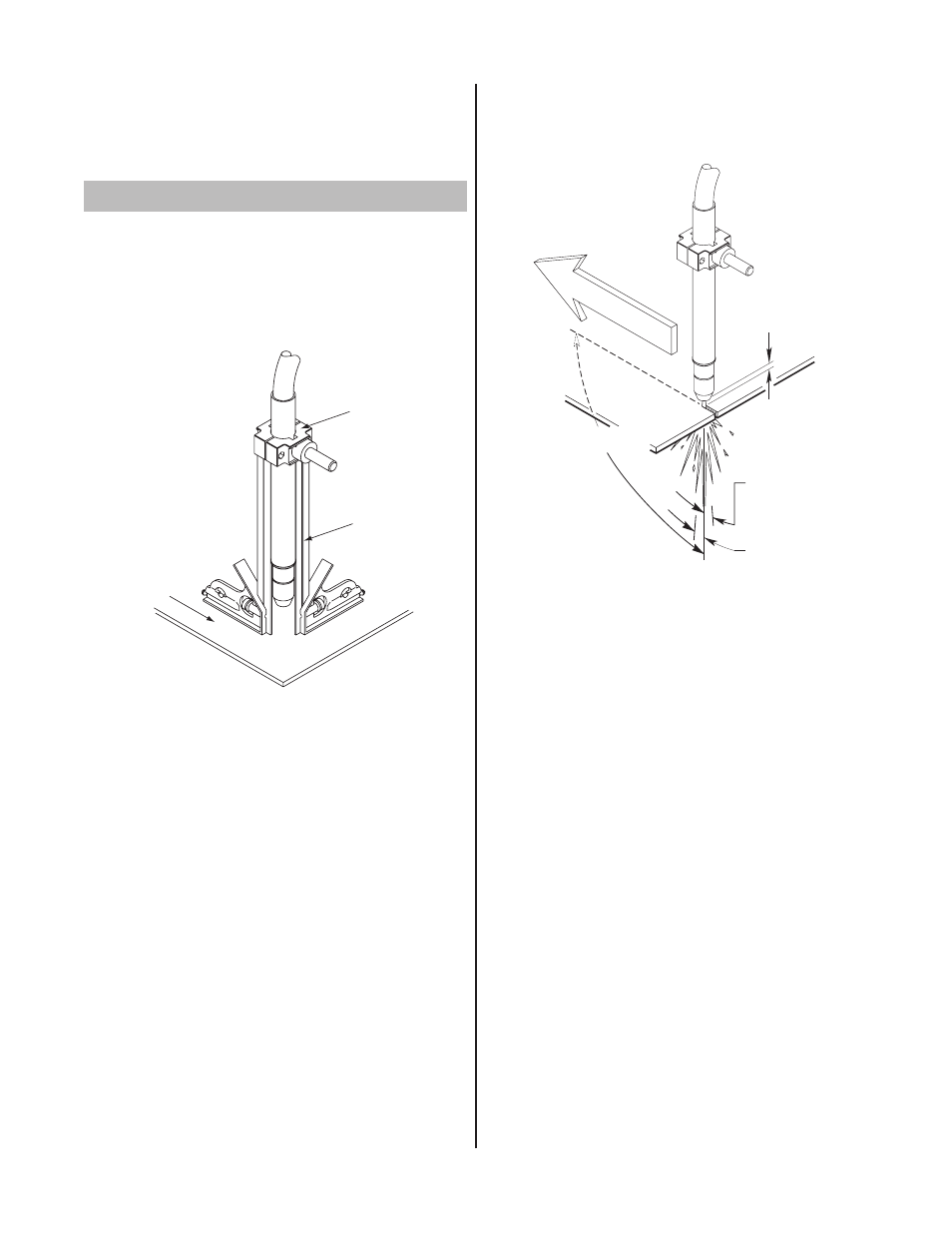

1. Use a square to check that the torch is perpendicu-

lar to the workpiece to obtain a clean, vertical cut

.

A-02585

Workpiece

Square

Pinch Block

Assembly

Checking Alignment

2. To start a cut at the plate edge, position the center

of the torch along the edge of the plate.

B. Travel Speed

Proper travel speed is indicated by the trail of the arc

which is seen below the plate. The arc can be one of

the following:

1. Straight Arc

A straight arc is perpendicular to the workpiece

surface. This arc is generally recommended for the

best cut using air plasma on stainless or aluminum.

2. Leading Arc

The leading arc is directed in the same direction as

torch travel. A five degree leading arc is generally

recommended for air plasma on mild steel.

3. Trailing Arc

The trailing arc is directed in the opposite direction

as torch travel.

Standoff Distance

Straight Arc

Trailing Arc

Leading Arc

Direction of Torch Travel

A-02586

Machine Torch Operation

For optimum smooth surface quality, the travel speed

should be adjusted so that only the leading edge of

the arc column produces the cut. If the travel speed

is too slow, a rough cut will be produced as the arc

moves from side to side in search of metal for transfer.

Travel speed also affects the bevel angle of a cut. When

cutting in a circle or around a corner, slowing down

the travel speed will result in a squarer cut. The power

source output should be reduced also. Refer to the

appropriate Control Module Operating Manual for any

Corner Slowdown adjustments that may be required.