Tweco PAK 10 User Manual

Page 23

Manual No. 0-0515

11

Operation

MACHINE TORCH OPERATION

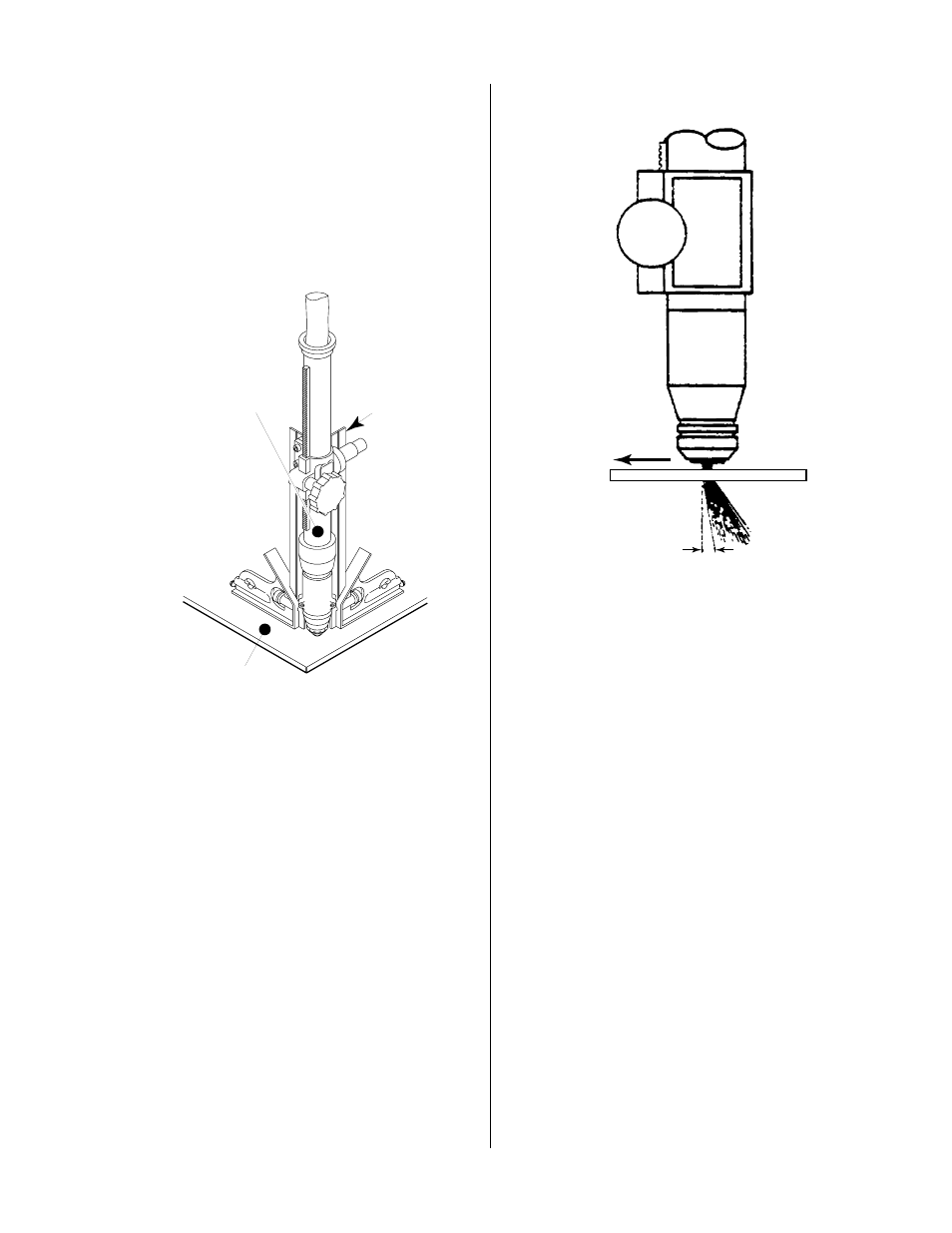

When cutting with a machine torch, the torch must be

at right angles to the plate to obtain a clean, vertical

cut. Use a square, as shown in Figure 3-D, to align the

torch. It is good to start a cut at a slow speed and in-

crease the speed to obtain the desired cut quality. Table

3-B gives typical cutting speeds for various materials

and material thicknesses.

A-00175

Rack and

Pinion Mounting

Assembly

Square

Workpiece

Figure 3-D Using a Square to Set Up the Machine

Torch

To start a cut at the plate edge, line up the torch away

from the plate, and press the control switch. The trans-

ferred cutting arc will then be established at the plate

edge. Adjust cutting speed for good cutting perfor-

mance, as indicated by a trailing arc of approximately

5° (Figure 3-E). When cutting expanded metal the cut-

ting arc and pilot arc will alternate establishing them-

selves automatically.

5˚ Approximately

Direction Of

Travel

A-01919

Figure 3-E A Good Cut Will Produce a Trailing

Arc of Approximately 5°

PIERCING

In some cutting operations, it may be desirable to start

the cut within the plate area rather than at the plate

edge. Piercing the plate is not recommended on plates

thicker than 3/4" (19 mm), based on a 5/16" (7 mm)

standoff, using a mechanized torch with a “running

start” and a maximum time to complete pierce of 3 sec-

onds). Blowback from the piercing operation can

shorten the life of torch parts. All piercing should there-

fore be done as quickly as possible with current set at

100 amperes.

A method called “running start” is recommended when

piercing with a machine mounted torch. Position the

torch off the cutting line a sufficient distance to allow

the pierce to be made before reaching the cutting line.

This allowance depends on the thickness of the mate-

rial and the travel rate of the mechanized torch.