Operation, 1 operating controls, 2 pre-operation set-up – Tweco PAK 10 User Manual

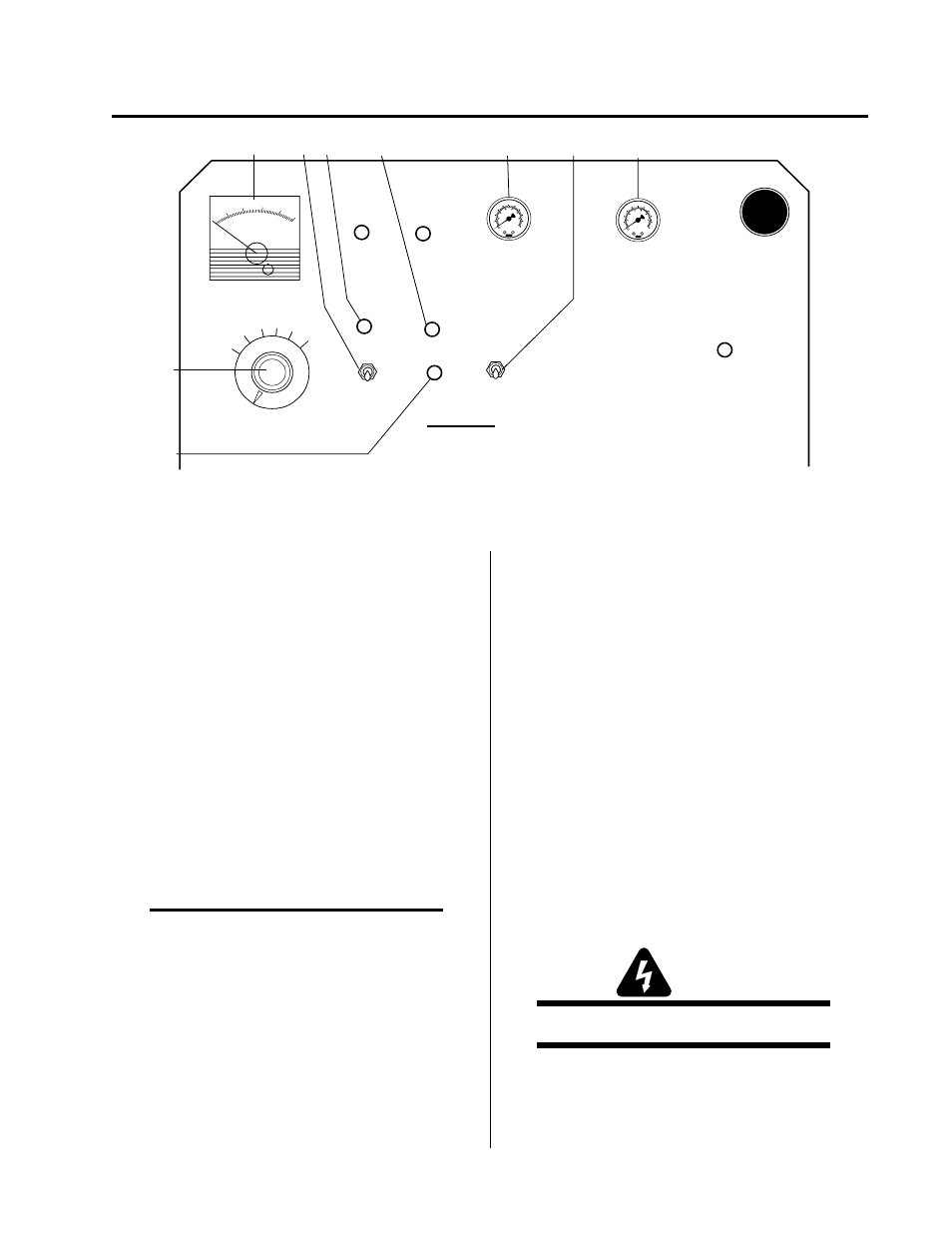

Page 21: Thermal arc pak 10, Figure 3-a pak 10 control unit operating controls

Manual No. 0-0515

9

Operation

3.1

OPERATING CONTROLS

1. Current Adjust Knob

Select desired cutting current. Calibrated from Min.

up to 100 amps.

2. Ammeter (A)

Indicates amperage supplied to torch.

3. READY Indicator (LT3)

Amber light indicates that the ON/OFF switch is

ON and that lead connection access door is closed.

4. AC POWER Indicator (LT1)

Red light indicates that 3 phase AC power is being

supplied to the system.

NOTE

Fan is on when this light is on.

5. PLASMA GAS

Indicates pressure at which plasma gas is being sup-

plied to the torch.

6. SECONDARY GAS

Indicates pressure at which secondary gas is being

supplied to the torch.

7. RUN/SET Switch (SW2)

Move up to RUN position for torch operation. Move

down to SET position for purging gas lines and set-

ting gas pressures with external regulators.

8. DC Power Indicator (LT2)

Red light indicates that main contactor (W) has

closed to supply current to the main bridge rectifier

and that cutting current is available.

9. ON/OFF Switch (SW1)

Move up to ON position to activate the control cir-

cuits. Move down to OFF position to deactivate

control circuits.

3.2

PRE-OPERATION SET-UP

This procedure should be followed at the beginning of

each shift:

WARNING

Check to be sure main disconnect switch is open.

l. Check the torch to be sure it has the proper compo-

nents and is adjusted correctly. (Refer to Section 4.1).

2. Close the main disconnect switch supplying 3- phase

power to the unit.

OPERATION

40

20

100

80

60

2

1

3

4

5

6

bar

psi

AMPERES

D.C.

CURRENT

50

60

70

80

90

100

40

20

100

80

60

2

1

3

4

5

6

bar

psi

PLASMA GAS

SECONDARY GAS

TORCH

1FU

2FU

10A

5A

ON

OFF

RUN

SET

AC POWER

DC POWER

REMOTE

CURRENT CONTROL

3

9

5

4

1

2

6

7

8

Thermal Arc PAK 10

CUTTING SYSTEM

MIN.

A-03309

Figure 3-A PAK 10 Control Unit Operating Controls