Tweco 1000 Merlin(Dec2004) User Manual

Page 27

Manual 0-2708

3-9

INSTALLATION

c. Connect the air supply hose (see note) to the Air Line

Filter input port (IN) barb fitting and secure with a cus-

tomer supplied hose clamp.

NOTE

The supply hose must be 1/4 inch (6.3 mm) mini-

mum inside diameter to provide adequate air flow.

D. Using Water Secondary

NOTES

Tap water should only be used as a secondary on

machine torches.

The tap water source does not need to be deionized,

but in water systems with extremely high mineral

content a water softener is recommended.

Tap water with high levels of particulate matter

must be filtered.

Tap water can be used instead of a secondary gas and is

connected to the Power Supply as follows:

1. The tap water source must be capable of delivering a

minimum water pressure of 50 - 100 psi (3.5 - 6.9 bar)

and flow of 9 gph (34 lph).

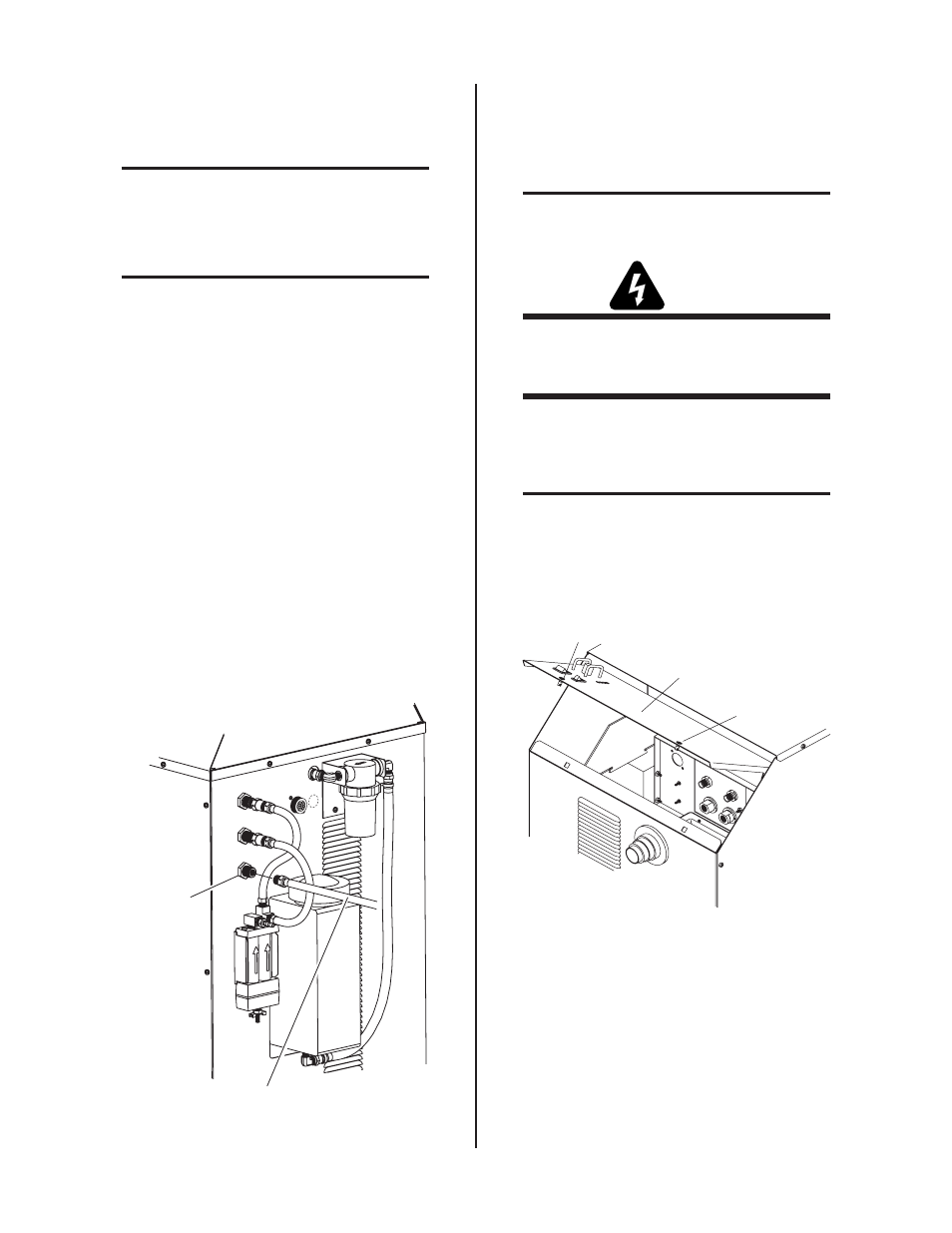

2. Connect the tap water supply hose to the input of a

Water Pressure Regulator.

3. Connect the output of the water regulator to the fitting

marked SECONDARY H2O (water) on the rear panel

of the Power Supply.

A-02164

Water Supply Hose

(Customer Supplied)

WATER

Secondary

Figure 3-11 Secondary Water Connection

3.09 Connecting Torch Leads To

System Without Optional

Remote Arc Starter

NOTE

For Systems using the Optional Remote Arc Starter

refer to Section 3.13 for connecting the Torch.

WARNING

Disconnect primary power at the source before as-

sembling or disassembling the power supply, torch

parts, or torch and leads assembly.

The Torch Leads must be properly installed to the Power

Supply for proper operation. Make all torch connections

to the Torch Bulkhead Panel as follows:

NOTE

Equipment ordered as a system will have the Torch

factory connected to the Power Supply.

1. Turn the two latch screws securing the Control/Access

Panel to the power supply front panel.

Control/Access Panel

Latch Screw

Latch Screw

A-02165

Figure 3-12 Front Control/Access Panel

Connect the CNC Control Cable and Torch Leads to the Power

Supply as follows:

2. Open the Access Panel to gain access to the Torch

Bulkhead Panel.

3. Remove the hardware attached to the power sup-

ply end of the leads assembly with a tie wrap.