04 cut quality, Cut quality -6, Cutmaster 15mm – Tweco 15mm Cutmaster User Manual

Page 28

cutmaster 15mm

OPERATION 4-6 Manual 0-5178

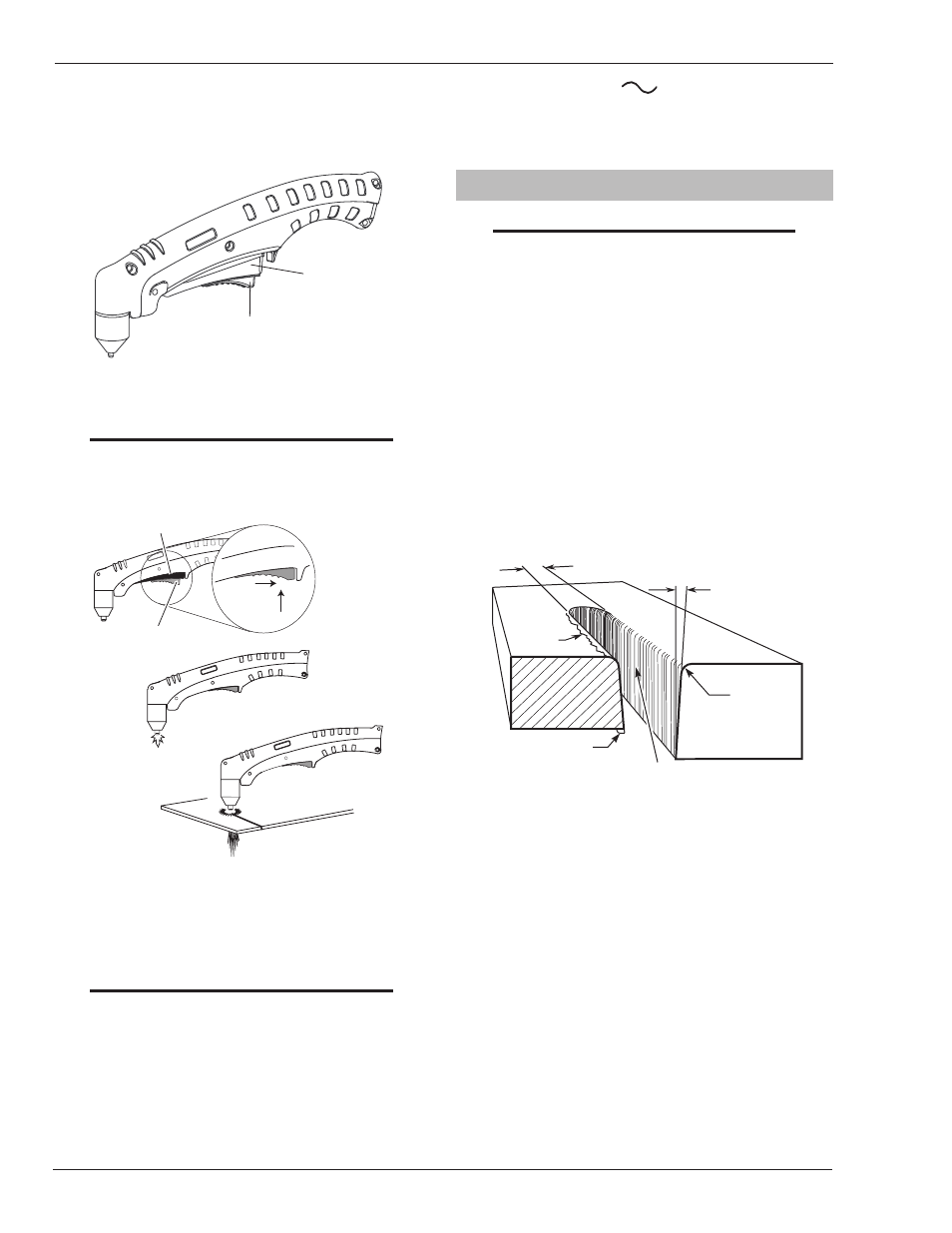

D. Hold the torch away from your body.

E. Slide the trigger release toward the back of the

torch handle while simultaneously squeezing

the trigger. The arc will start.

Art # A-03962

Trigger

Trigger Release

F. Place the torch tip on the work. The main arc

will transfer to the work.

NOTE

The gas preflow and postflow are a character-

istic of the power supply and not a function

of the torch.

3

4

Art # A-03383

Trigger

2

1

Trigger Release

G. Cut as usual. Simply release the trigger as-

sembly to stop cutting.

H. Follow normal recommended cutting practices

as provided herein.

3. Complete cutting operation.

NOTE

If the torch is lifted too far from the workpiece

while cutting, the main arc will stop and the

pilot arc will automatically restart.

4. Release the torch trigger.

a. Main arc stops.

5. Set the power supply ON / OFF switch to OFF

(down position).

a. AC indicator

turns OFF.

6. Set the main power disconnect to OFF, or unplug

input power cord.

a. Input power is removed from the system.

4.04 Cut Quality

NOTE

Cut quality depends heavily on setup and

parameters such as torch standoff, alignment

with the workpiece, cutting speed, gas pres-

sures, and operator ability.

Refer to appendix pages for additional infor-

mation as related to the power supply used.

Cut quality requirements differ depending on application.

For instance, nitride build-up and bevel angle may be ma-

jor factors when the surface will be welded after cutting.

Dross-free cutting is important when finish cut quality

is desired to avoid a secondary cleaning operation. The

following cut quality characteristics are illustrated in the

following figure:

Kerf Width

Cut Surface

Bevel Angle

Top Edge

Rounding

Cut Surface

Drag Lines

Dross

Build-Up

Top

Spatter

A-00007

Cut Quality Characteristics

Cut Surface

The desired or specified condition (smooth or rough)

of the face of the cut.

Nitride Build - Up

Nitride deposits can be left on the surface of the cut

when nitrogen is present in the plasma gas stream.

These buildups may create difficulties if the material

is to be welded after the cutting process.

Bevel Angle

The angle between the surface of the cut edge and

a plane perpendicular to the surface of the plate. A