09 pilot and power lead connections, 09 pilot and power lead connections -5 – Tweco Merlin 6000 Plasma Cutting CE Slave Power Supply User Manual

Page 21

Manual 0-2603

3-5

INSTALLATION PROCEDURES

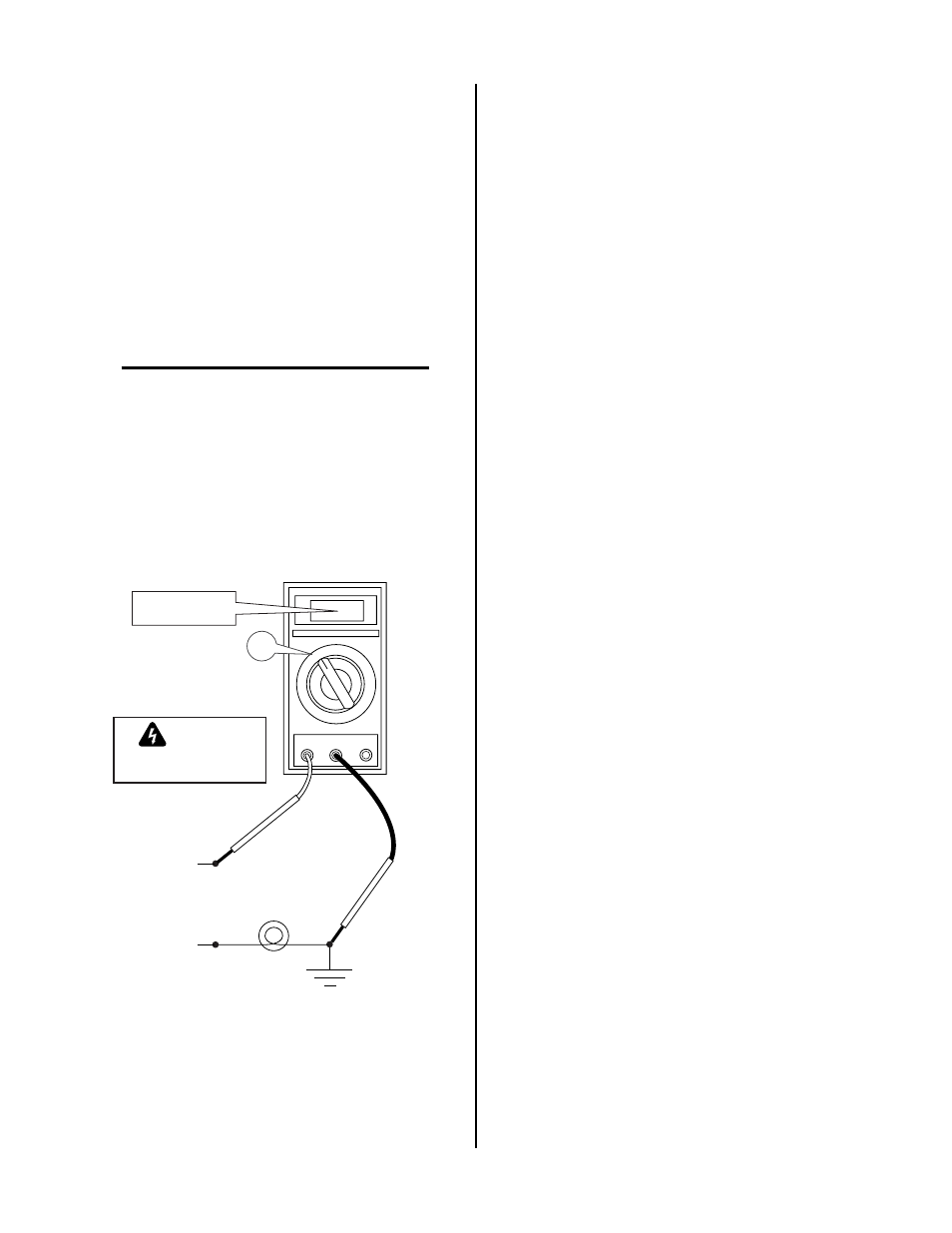

C. Creating An Earth Ground

1. To create a solid, low resistance, earth ground, drive a

1/2 in (12 mm) or greater diameter copper clad ground

rod at least 6 - 8 ft (1.8 - 2.4 m) into the earth so that

the rod contacts moist soil over most of its length.

Depending on location, a greater depth may be re-

quired to obtain a low resistance ground (see NOTE).

Ground rods, typically 10 ft (3.0 m) long, may be

welded end to end for greater lengths. Locate the rod

as close as possible to the work table. Install a ground

wire, 1/0 AWG (50.0 mm

2

European) or greater, be-

tween the ground rod and the star ground point on

the cutting table.

NOTE

Ideally, a properly installed ground rod will have a

resistance of three ohms or less.

To test for a proper earth ground, refer to the follow-

ing diagram. Ideally, the reading on the multimeter

should be as follows:

• For 115VAC: 3.0 VAC

• For 230VAC: 1.5 VAC

A-02971

+

_

Meter set to

VAC setting

Machine

Earth Ground

Neutral

Line (Hot)

100W

Light Bulb

115 or 230VAC

WARNING

Use extreme caution. This

test uses live voltage.

115VAC: 3.0 VAC

230VAC: 1.5 VAC

V

~

V

~

VR COM A

Ground Testing

2. Increasing the ground rod length beyond 20 - 30 ft

(6.1 – 9.1 m) does not generally increase the effective-

ness of the ground rod. A larger diameter rod which

has more surface area may help. Sometimes keeping

the soil around the ground rod moist by continuously

running a small amount of water into it will work.

Adding salt to the soil by soaking it in salt water may

also reduce its resistance. When these methods are

used, periodic checking of the ground resistance is re-

quired to make sure the ground is still good.

D. Routing Of Torch Leads

1. To minimize RF interference, position torch leads as

far as possible from any CNC components, drive mo-

tors, control cables, or primary power lines. If cables

have to pass over torch leads, do so at an angle. Do

not run the plasma control or other control cables in

parallel with the torch leads in power tracts.

2. Keep torch leads clean. Dirt and metal particles bleed

off energy, which causes difficult starting and in-

creased chance of RF interference.

3.09 Pilot and Power Lead

Connections

The Slave Power Supply pilot and negative DC power

connects directly to connections inside the Arc Starter Box

and the Power Supply. Make the connections to the per

the following procedure:

1. Remove the cover from the Arc Starter Box.

2. Feed the Slave Power Supply pilot lead through

the boot at the end of the Arc Starter Box.

3. Connect the pilot lead to the pilot connection per

the following procedure:

a. Remove the nut and external star washer from

the pilot connection bolt.

b. Place the ring lug on the pilot wire over the

end of the bolt.

c. Re-install the external star washer and nut to

secure the lead.