6 controller parts list – pc20, 7 clean-up, 8 disassembly – Trebor SL20 CHAMPION User Manual

Page 21

CHAMPION SL20 PUMP OPERATION / MAINTENANCE MANUAL

PAGE 21

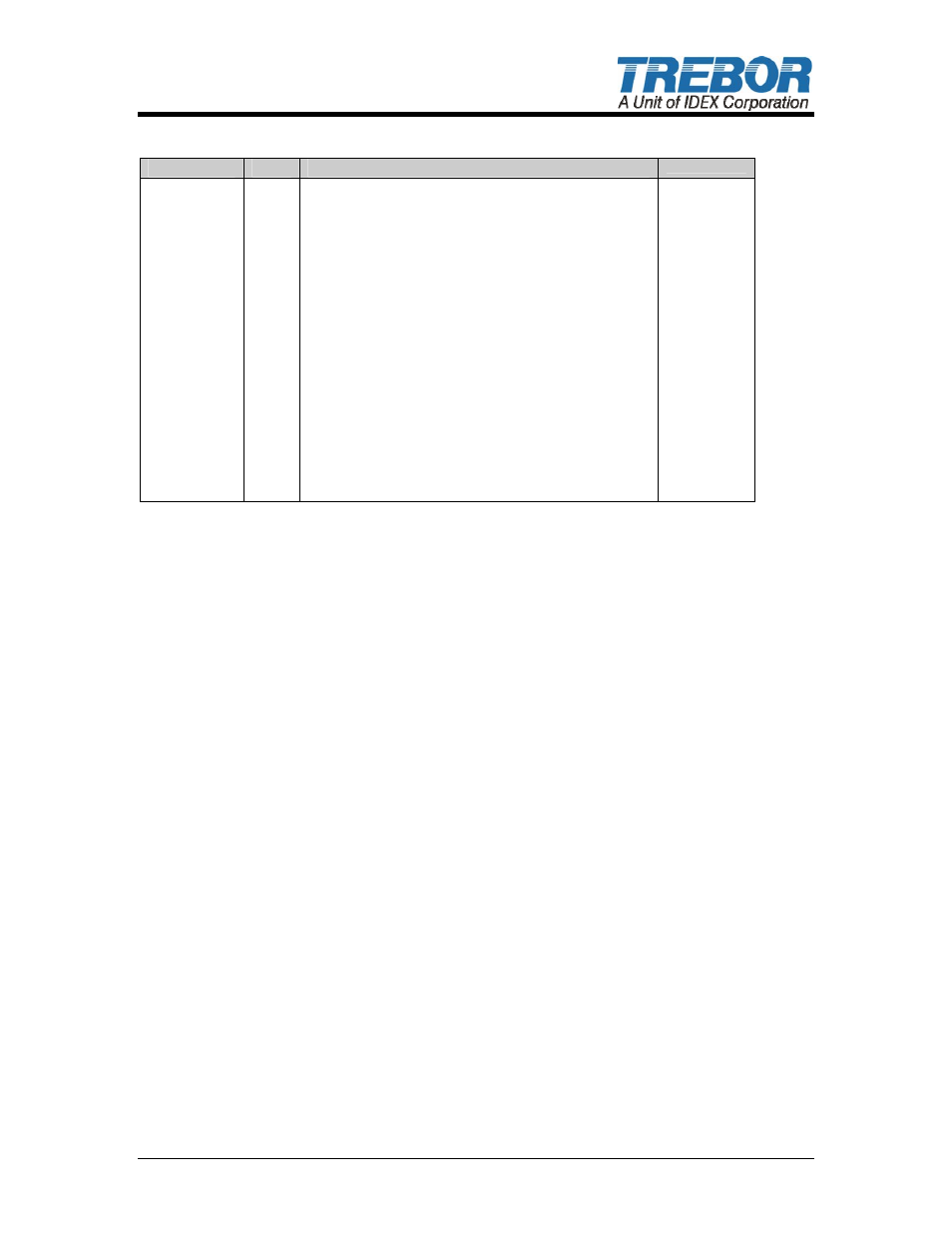

4.6 CONTROLLER PARTS LIST – PC20

PART NO

QTY

DESCRIPTION

98001151

.33 ft.

Tube, Polye, 3/8’OD, .06W

98001153

12 ft.

Tube, HDPE, Natural, 1/4 Diameter

98001590 13

ft.

Wire,18G,Wht/Blu

98001620

14 ft.

Wire,18G,Lt Blu

98002088

1 ft.

Rail, Din 3, 35 x 7.5 x 1

98002504

1

End, Terminal Stop, Pin

98002871

3

Block, Terminal, Multi

98002872 1

End,Terminal,Multiclamp,Din

98002672 2

Sensor,Fiberoptic,

24VDC,NPN

98003287

1

Fitting, VAC, Gen, Hiflow, 5/1

98003288

1

Fitting, ACTL, 5/16T x 5/16T x 3/8

98003289

2

Fitting, ACTL, 5/16T x 3/8T, Red

98003703

1

Fitting, ACTL, PC, 3/8Tx1/4P, FC

98003290

1

Fitting, ACTL, 3/8T, Tee, PC

98003292

13.5 ft

Tube, HDPE, Natural, 5/16 Diameter

98003293

12 ft.

Tube, HDPE, Black, 5/16 Diameter

98003294

12 ft.

Tube, HDPE, Black, 1/4 Diameter

98003503 1

Controller,PLC,16

I/O,24VDC

AS014

1

Assembly, Valve, 4 POS, VQ2000

BB024

1

Assembly, Muffler, Non-ADJ

4.7 CLEAN-UP

To help remove potentially dangerous chemicals prior to service or shipment, the

pump should be flushed with DI water or disassembled and thoroughly cleaned.

Allow DI water to flush through the inlet and out the outlet to prevent pressure

build up.

4.8 DISASSEMBLY

During the life of the pump it will be necessary to perform certain preventative

maintenance procedures to ensure its continued high performance. This section

and the next (4.9 Assembly) are provided for the user’s convenience in

disassembly and re-assembly procedures.

• Loosen quick grip nuts on the transfer tubes from the pump base using

13/16” open-end wrench.

• Remove pump assembly from the pump control base.

• Immerse or flush the pump assembly using DI water and a neutralizing agent.

• Remove suction check caps and seal on bottom of pump body using T0145

pin tool.

• Remove ball, O-ring and cap seal.

• Remove discharge check caps and seal on outlet side of pump.

• Remove ball, O-ring, and cap seal.

4.8.a Body

Disassembly

• Install mounting fittings in pump discharge check ports on top of the pump.

Turn over and lock body into bench mounting fixture. NOTE: Securely attach

mounting fixture to work surface using hardware provided.

• Remove the transfer tubes from pump heads using 1/4” Allen wrench.