tekmar 420 Boiler Reset Module User Manual

Page 16

© 2007

D 420 - 08/07

16 of 24

In some cases, multiple boilers may be required. In these

cases, the 420 allows for a connection to a tekmar Boiler

Control 264, 265, or 268. The 420 uses the modulating

output to provide a 0-10 V (dc) signal to the external input

terminals on the Boiler Control. The 420 controls the Boiler

tekmar Stager Operation

Section D

Boiler Motor Speed

The Boiler Motor Speed is the amount of time the boiler

requires to go from 0% modulation to 100% modulation.

Gas valve actuating motors have a design time from fully closed

to fully open which can be found in the manufacturer’s manual.

The Boiler Motor Speed should be set to this time.

The Boiler Motor Speed setting for a Variable Frequency

Drive (VFD) is the amount of time required to go from a

stopped position to 100% fan speed. Since a VFD has a

very quick response rate, it may be necessary to increase

the Motor Speed setting in order to increase the stability

of the boiler modulation.

•

• Locate the Boiler Motor Speed setting in the Adjust menu.

Minimum Modulation

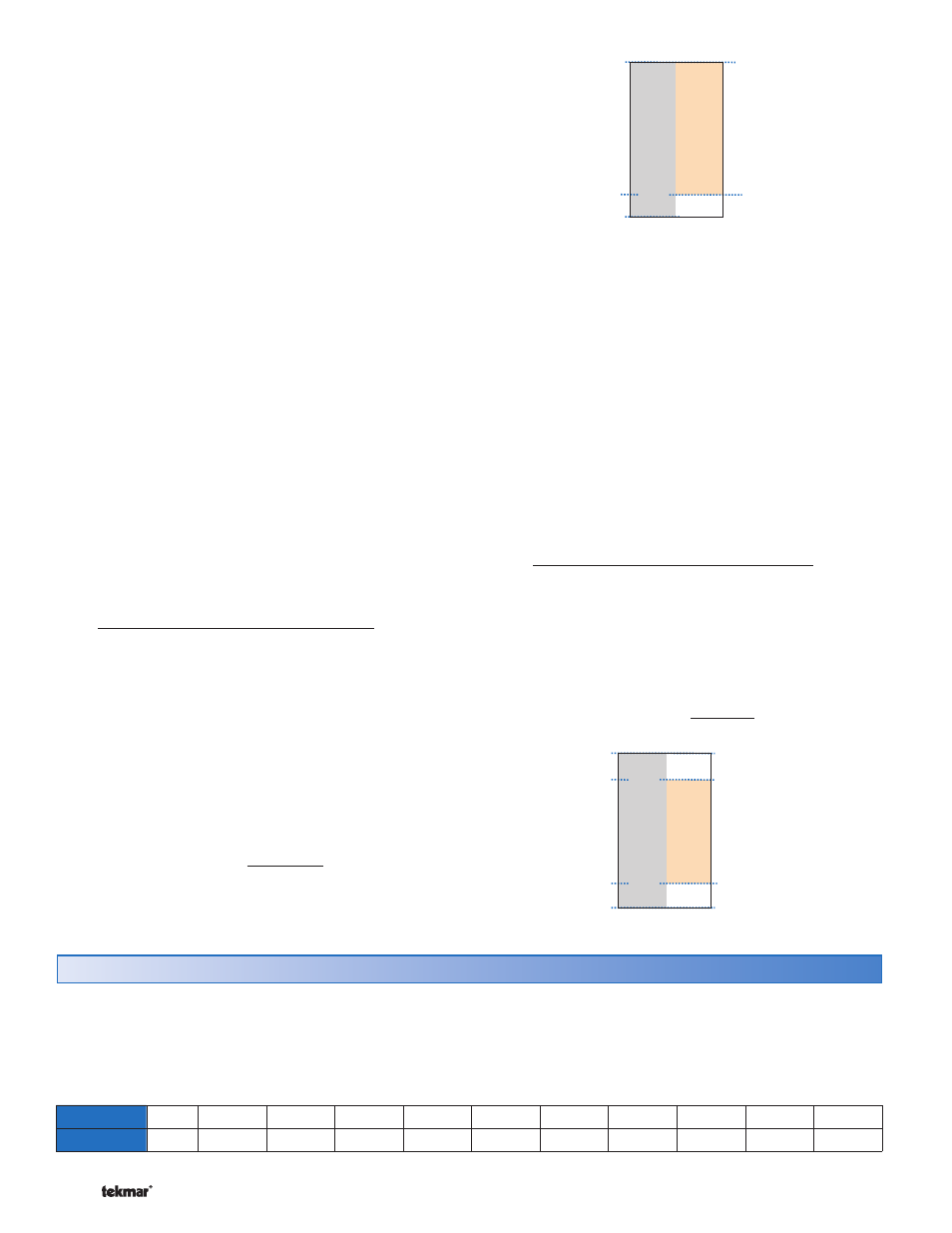

The minimum modulation defines the minimum output

signal from the control to the boiler burner. It is based on

a percentage of the control’s output signal range.

The Minimum Modulation default setting is 0%.

For boilers with electronic operators, the boiler’s input signal

range may not match the output signal range of the 420

control. The Minimum Modulation setting limits the control

output range in order to match the boiler’s input range.

•

• Locate the Minimum Modulation setting in the Adjust menu.

To calculate the Minimum Modulation, use the following

formula:

For 0-10 V (dc):

Minimum Modulation =

0 V (dc) – Boiler’s Minimum Input Signal x 100%

0-10

V

(dc)

Example:

A boiler requires a 1.8 V (dc) signal to fire the boiler at

low fire. The boiler can be modulated to 10 V (dc) where

it reaches high fire.

This means the boiler’s input signal range is 1.8 to

10 V (dc). The 420 control has an output signal range of

0-10 V (dc).

To make the two signal ranges the same, the Minimum

Modulation required is:

Minimum Modulation = 0 V-1.8 V x 100% = 18%

0

V-10

V

1.8 V (dc)

10 V (dc)

Control Rang

e

Boiler Rang

e

0 Vdc

18%

Maximum Modulation

The maximum modulation defines the maximum output

signal from the control to the boiler burner. It is based on

a percentage of the control’s output signal range.

The Maximum Modulation default setting is 100%.

For boilers with electronic operators, the boiler’s input signal

range may not match the output signal range of the 420

control. The Maximum Modulation setting limits the control

output range in order to match the boiler’s input range.

•

• Locate the Maximum Modulation setting in the Adjust

menu.

To calculate the Maximum Modulation, use the following

formula:

For 0-10 V (dc):

Maximum Modulation =

0 V (dc) – Boiler’s Maximum Input Signal x 100%

0-10

V

(dc)

Example:

A boiler’s input signal range is 2-9 V (dc). The 420 control

has an output signal range of 0-10 V (dc).

To make the two signal ranges the same, the Maximum

Modulation required is:

Maximum Modulation = 0 V-9 V x 100% = 90%

0

V-10

V

10 V (dc)

Control

Rang

e

Boiler

Rang

e

0 Vdc

0 V (dc)

2.0 V (dc)

20%

90%

Voltage (dc)

0

1

2

3

4

5

6

7

8

9

10

Boiler Target

Off

50°F

(10°C)

68°F

(20°C)

86°F

(30°C)

103°F

(40°C)

121°F

(50°C)

139°F

(60°C)

157°F

(70°C)

174°F

(80°C)

192°F

(90°C)

210°F

(99°C)

Control target temperature by changing the voltage signal.

The Boiler Control responds to the boiler target by staging

the multiple boilers.

The following table can be used to convert a 0-10 V (dc)

signal to a boiler target temperature: