Sizing the transformer control wiring – tekmar 403 House Control Installation User Manual

Page 4

© 2011

D 403 - 07/11

4 of 32

DHW Pump

Power

Source 1

Variable

Speed Pump

Boil System

Pump

The control requires an external transformer with 20 VA

capacity or greater. A tekmar Transformer 009 (or 009K

which includes a 4” x 4” electrical box) can supply up to 40

VA, and includes an in-line fuse to protect the transformer

and control.

Sizing the Transformer

Control Wiring

Line Voltage Wiring-----------------------------------------------------------------------------------

-----------------------------------------------------------------------------------

Ensure Junction Box Extension Ring is Installed

An extension ring must be installed on the 4” x 4”

junction box when 6 or more powered outputs for the

pumps are used on the rear of the control.

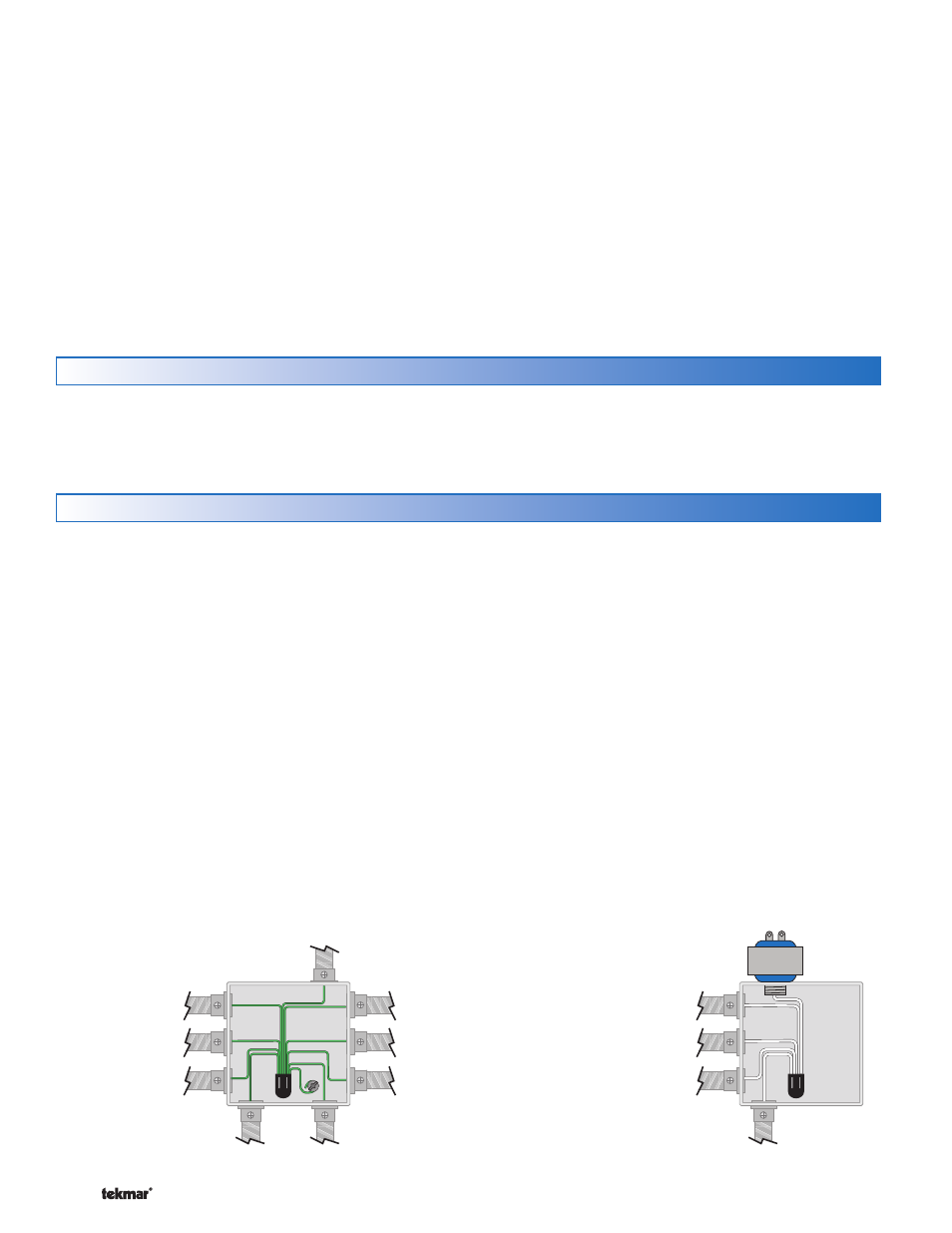

Ground the Pumps

Connect the pump grounds to the power supply

ground as shown in Figure 1. The ground wire must

also be grounded to the electrical box.

Wire the Pump Neutrals

If the combined pump power load is less than 12 A,

then a only a single 15 A circuit is required.

If the combined pump power load exceeds 12 A, then

two separate 15 A circuits are required.

Each power circuit requires it’s own neutral wire.

Connect the Neutral (N) wires from each pump and wire

to the 115 V (ac) Neutral (N) wire. If the transformer has

•

•

•

•

•

•

been mounted to this electrical box, connect its neutral

wire with this group. This is shown in Figure 2 and 3.

Wire the Pump Power (L)

If the combined pump power load is less than 12 A,

then a only a single 15 A circuit is required.

If the combined pump power load exceeds 12 A, then

two separate 15 A circuits are required.

Connect the 115 V (ac) line voltage (L) wire to the red

Pump Power (L) wire on the back of the House Control

and to the 115 V (ac) side of the transformer. Use a

wire nut or approved connector. See Figure 4.

Wire the Pumps

Wire each remaining line voltage pump wire into the

push-in wire connector of the corresponding pump

lead on the back of the House Control. This is shown

in Figure 5 and 6.

•

•

•

•

CAUTION: TURN ALL POWER OFF BEFORE PERFORMING ANY WIRING.

DHW Pump

Power

Source 1

Power

Source 2

Zone 4 Pump

Zone 3 Pump

Zone 2 Pump

Zone 1 Pump

Variable

Speed Pump

Boil System

Pump

Figure 1 - Connect

Ground Wires

Figure 2 - Connect Neutral Wires

for Power Source 1

Each cable must be pulled from the equipment to the

control’s plastic enclosure. All low voltage wiring connections

enter the enclosure through conduit knockouts on the

sides, or through the square knockouts on the rear. It is

recommended to label each cable for easy identification.

All low voltage wires are to be stripped to a length of 3/8”

(9 mm) to ensure proper connection to the control.

Pull two conductor 18 AWG LVT cable, up to 500 feet

(150 m) for the following equipment:

tekmarNet

®

2 Thermostats

Mixing Valve Actuator Proportional 0-10 V (dc)

Boiler Stage 1 T-T

Boiler Stage 2 T-T (if applicable)

•

•

•

•

Modulating Boiler 0-10 V (dc) or 4-20 mA (if applicable)

Outdoor Temperature Sensor

Boiler Supply Temperature Sensor

Mix Supply Temperature Sensor

DHW Tank Temperature Sensor (if applicable)

DHW Tank Aquastat (if applicable)

Setpoint Device (if applicable)

Pull three conductor 18 AWG LVT cable for the following

equipment:

Mixing Valve Actuator Floating Action

tekmarNet

®

4 Accessories (User Switch, Timer)

•

•

•

•

•

•

•

•

•

Low Voltage Wiring -----------------------------------------------------------------------------------

-----------------------------------------------------------------------------------