tekmar 370 House Control User Manual

Page 7

Copyright © D 370 -06/99

7 of 20

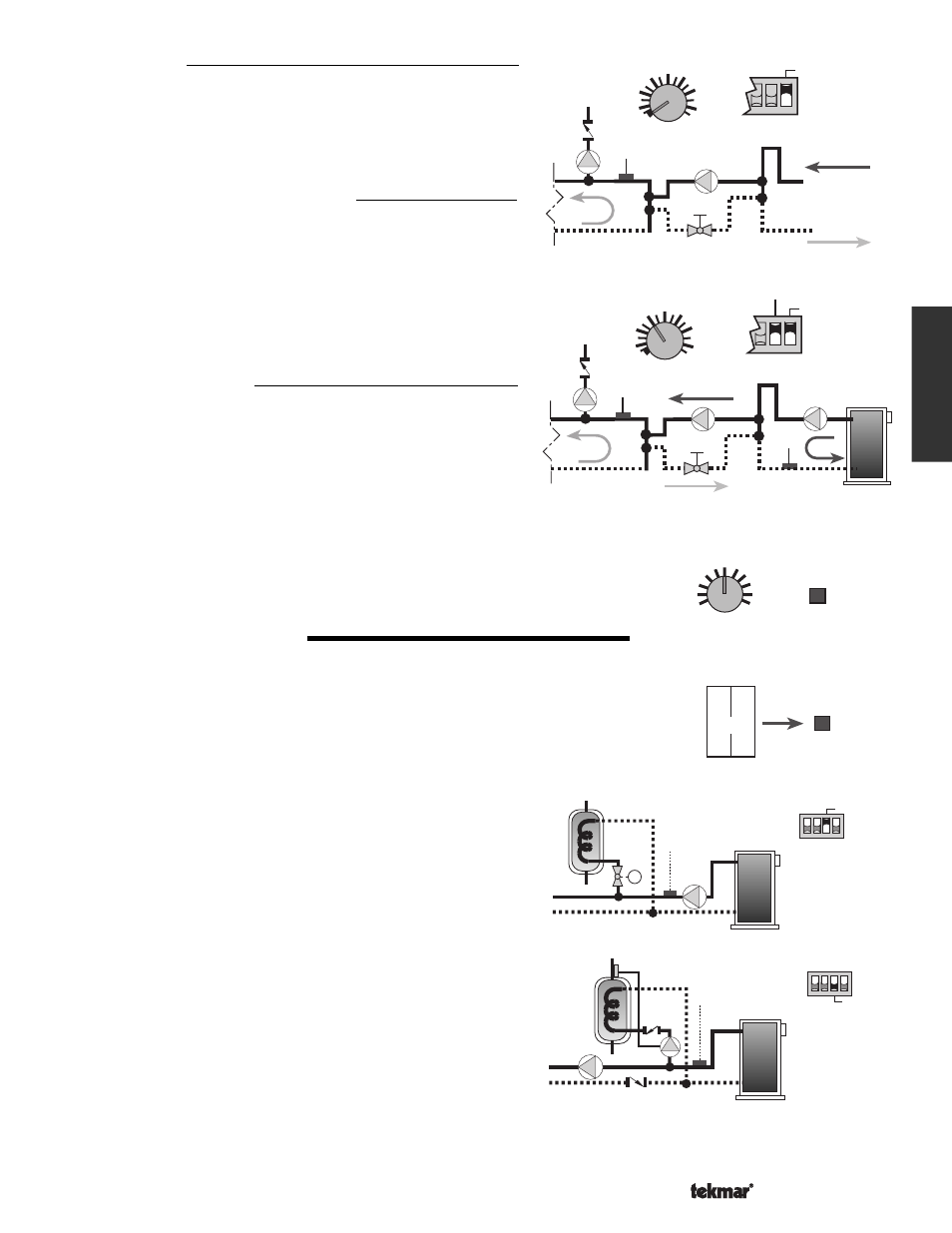

Boiler Enable

If no Boiler Sensor is installed and the

Min. Boiler Supply dial is set to

the

Off position, the Boiler relay can be used to provide a heat demand

to an external multiple boiler staging control. In order to prevent short

cycling the 370 turns on the

Boiler relay when the variable speed

output is between 10% and 25%. The

Boiler relay then has a minimum

on time of 3 minutes and a minimum off time of 20 seconds.

Boiler Enable With Boiler Protection

Only when the boiler supply water temperature is measured by a boiler

return sensor, can the 370 provide direct boiler protection. The DIP

switch must be set to

Boiler Return. The aquastat in the boiler should

be set to Boiler Outdoor design water temperature. When the boiler is

fired and the boiler return temperature is near (or below) the

Min. Boiler

Supply dial setting, the 370 turns on the Minimum Boiler light and

reduces the heating load on the boiler. During this warm up period, the

injection pump is run at a slower speed and some of the zones may be

prevented from operating.

Boiler Load Reduction

When the

Boiler relay is turned on after a period of no operation, the

370 only allows one zone to operate until the boiler supply water

temperature reaches the

Min. Boiler Supply setting and the system

supply water temperature approaches the target supply temperature.

This helps the boiler to warm up as fast as possible. Once the target

system supply water temperature is reached, the other zones are

allowed to operate.

Maximum System Supply

The 370 has a

Max. System Supply dial that can be used to set an upper limit to the system

supply water temperature. If the supply water temperature approaches the

Max. System

Supply dial setting, the 370 turns on the Maximum Supply light and reduces the speed

of the injection pump.

DOMESTIC HOT WATER (DHW)

The DHW tank requests heat from the 370 through a DHW Demand. Whenever 24 V (ac)

or 120 V (ac) is applied to the

DHW Dem — DHW Dem (22 and 23) terminals on the 370,

the control registers a DHW Demand and turns on the

DHW Demand light. An aquastat,

setpoint control or other switching device can be used to generate a DHW Demand by wiring

the voltage signal through the switching device and into the

DHW Dem — DHW Dem

terminals.

DHW Valve / DHW Pump

Once the 370 has received a DHW Demand, the sequence of opera-

tion is dependent on the position of the

DHW Valve / DHW Pump

DIP switch.

DHW Valve (Boiler Operation)

If the DIP switch is set to

DHW Valve, the system pump is turned on

and the DHW valve is opened through the

DHW Pmp / Vlv relay. The

370 assumes a fast acting zone valve is used and the

Thermal Motor

DIP switch has no effect on the operation of the

DHW Pump/ Vlv relay.

DHW Valve (Mixing Operation)

If the DIP switch is set to

DHW Valve, the DHW valve is opened

through the

DHW Pmp / Vlv relay. The boiler loop pump must be

turned on through an external relay that is operated by the DHW valve

end switch.

DHW Pump (Boiler or Mixing Operation)

If the DIP switch is set to

DHW Pump, the 370 turns on the DHW

Pump through the

DHW Pmp / Vlv relay. Operation of the system

and boiler pump is not required (See application A 370-5).

DHW Supply Temperature

During the DHW operation, the 370 targets a boiler water temperature of at least 180

°F (82°C).

Max. System

Supply

120

170

°F

220

Maximum

Supply

22 23

DemDem

DHW

DHW

Demand

P

M

DHW Valve

P

DHW Pump

Supply

Sensor

130

°F

Off

165

Min. Boiler

Supply

100

From Heat Source

To Heat Source

Mixing

Operation

Boil

Sensor

Supply

Sensor

130

°F

Off

165

Min. Boiler

Supply

100

Mixing

Boiler Return