Sequence of operation – tekmar 361 Mixing Control User Manual

Page 4

Copyright © D 361 -

03/09

4 of 20

Sequence of Operation

Section A

General Operation

Page 4-5

Section B

Mixing

Page 5-8

Section C

Boiler Operation

Page 8-9

Section A —General Operation

POWERING UP THE CONTROL

When the Mixing Control 361 is powered up, the control displays the control type number in the LCD for 2 seconds. Next, the software

version is displayed for 2 seconds. Finally, the control enters into the normal operating mode.

OPERATION

The 361 uses a variable speed injection pump to control the supply water temperature to a hydronic system. The supply water

temperature is based on either the current outdoor temperature, or a fixed setpoint.

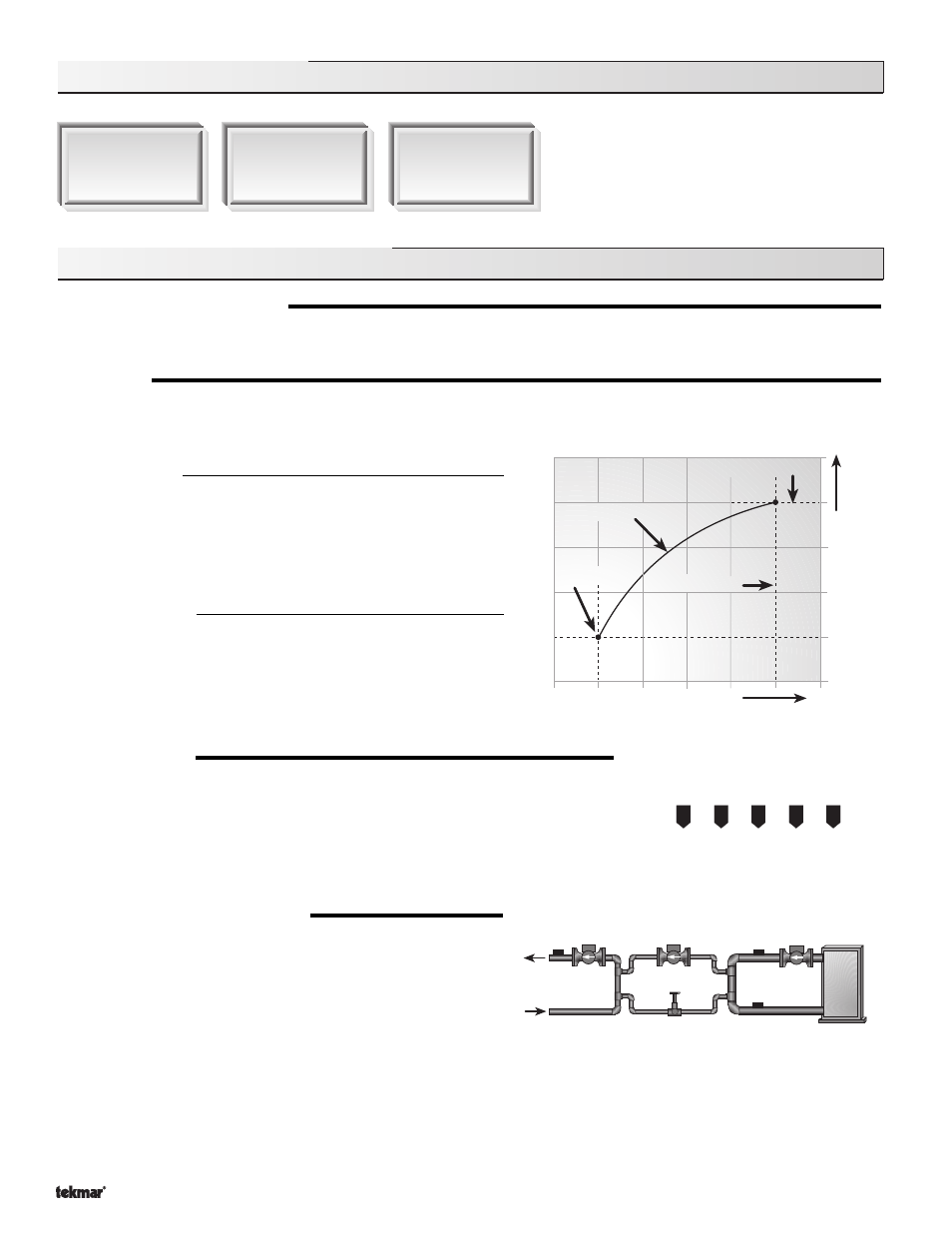

Outdoor Reset

When the outdoor design (OUTDR DSGN) setting is not set to OFF, the

361 calculates a mixing supply temperature based on the outdoor air

temperature. The 361 uses a

Characterized Heating Curve and

optionally indoor temperature feedback from an indoor sensor in this

calculation.

Setpoint Control

When the outdoor design (OUTDR DSGN) setting is set to OFF, the

361 supplies a fixed mixing supply temperature equal to the MIX

TARGET setting. An outdoor sensor is not required during this mode

of operation.

VARIABLE SPEED

A standard wet rotor circulator is connected to the 361 on the

Var Pmp and N terminals (7

and 8). The 361 increases or decreases the power output to the circulator when there is a

mixing demand. The circulator speed varies to maintain the correct mixed supply water

temperature at the mix sensor. For correct sizing and piping of the variable speed driven

circulator, refer to essay E 021. A visual indication of the current variable speed output is

displayed in the LCD in the form of a horizontal bar graph.

BOILER PROTECTION (BOIL MIN)

The 361 is capable of providing boiler protection from cold mixing system

return water temperatures. If the boiler sensor temperature is cooler than

the BOIL MIN setting while the boiler is firing, the 361 reduces the output

to the variable speed injection pump. This limits the amount of cool return

water to the boiler, and allows the boiler temperature to recover. This

feature can only be used if a boiler sensor is installed.

% Out

Current output of variable

speed injection pump

30

10

70

50

90

Mixing

sensor

Boiler return

sensor

Boiler supply

sensor

or

Outdoor Design

Increasing W

ater

T

emperature

Design Supply

Decreasing Outdoor Temperature

Terminal Unit

Indoor Design