Troubleshooting – Brother BAS-311F-L User Manual

Page 75

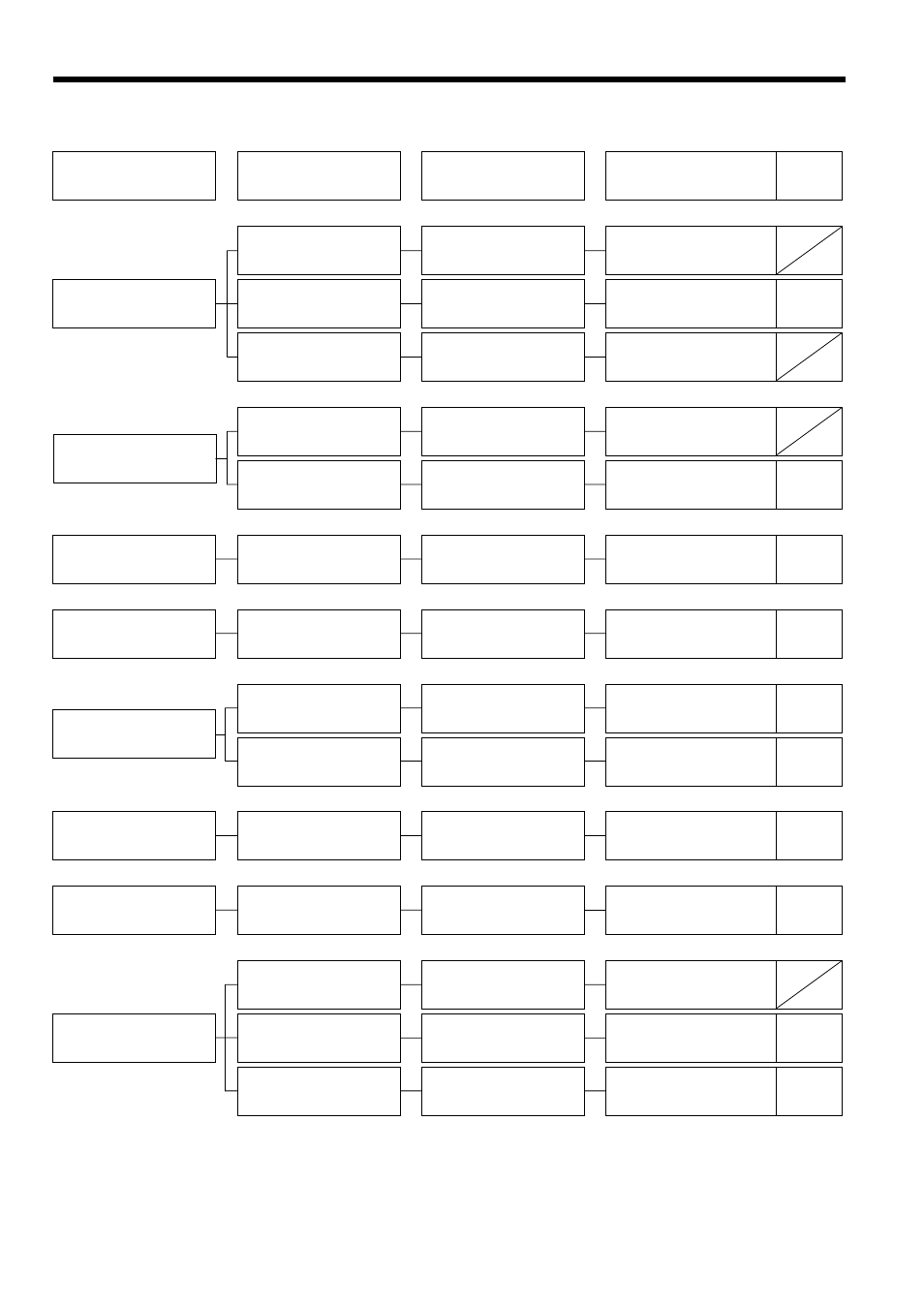

14. TROUBLESHOOTING

BAS-311F-0, 311F-L, 326F-0

68

14. TROUBLESHOOTING

* .........For Air type

Problem

Cause

Check

Remedy

Page

Work clamp operation

is sluggish.

Sliding part of the work

clamp lubrication

Presser lifter air tube is

bent or damaged.*

Pressure lifter air tube

Presser lifter link is not

moving back.

Link return spring is

unhooked.

Presser does not drop.

Work clamp operation

is sluggish.

Sliding part of the work

clamp lubrication

Presser lifter air tube is

bent or damaged.*

Presser lifter air tube

Grease the sliding part of

the work clamp.

Straighten the bend in the

tube or replace the tube.

Hook the link return

spring properly.

Grease the sliding part of

the work clamp.

Straighten the bend in the

tube or replace the tube.

18

18

Presser does not rise.

Incorrect position of

presser arm lever F.

Distance between work clamp

and top of needle plate

Work clamp pressure is

too light.

Check the setting of the

memory switch (memo-35).

The thread wiper is

obstructing the needle.

Clearance between thread

wiper and needle tip

Thread wiper position is

incorrect.

Thread wiper position

Adjust the work clamp lift

amount.

49

Increase the setting value

of the memory switch

(memo-35).

62

Adjust the height of the

thread wiper.

48

Adjust the operating distance

of the thread wiper.

48

Lower thread winds to

one side.

Bobbin winder thread

tension stud heights is

incorrect.

Bobbin winder thread

tension stud height

Lower thread winding

amount is incorrect.

Bobbin presser position

is incorrect.

Thread winding amount

Adjust the height of the

thread tension stud.

23

Adjust the position of the

bobbin presser.

23

Stitches being skipped

at the sewing start.

Refer to “Skipped

stitches occur”.

Thread slips out of the

needle.

Uneven upper thread

length.

Upper thread length

Position of shuttle race

thread guide is incorrect

Position of shuttle race

thread guide

Refer to “Skipped

stitches occur”.

Adjust the sub-tension.

25

Adjust the position of the

shuttle race thread guide

43

Thread wiper does not

operate correctly.

Presser lift amount is

incorrect.

Solenoid-type work clamp

lifts up without clamping

the material.