GBC 2064WF User Manual

Page 24

GBC 2064WF-1

Operation Manual

© 2009 General Binding Corporation an ACCO Brands CO. Page 24

MOUNT

ADHESIVE

ROLL TO ROLL OPTION

IMAGE

RELEASE LINER FROM PSA FILM

OUTPUT

THERMAL

OR PSA

FILM

DECAL

BOARD

RELEASE LINER

THERMAL

FILM

ROLL TO ROLL OPTION

IMAGE

OUTPUT

THERMAL

FILM

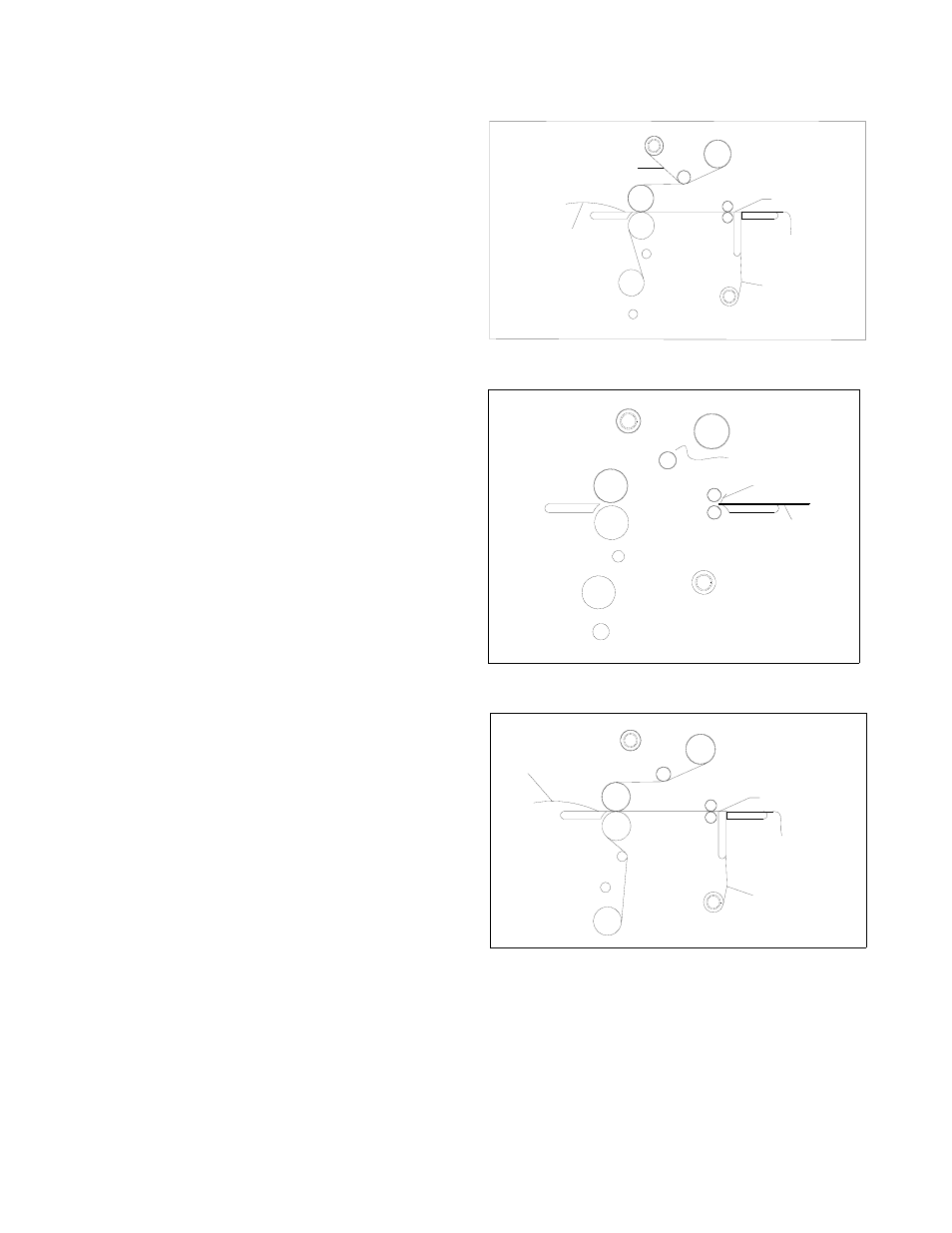

FIGURE 33

FIGURE 34

FIGURE 35

Tips for Creating a Decal

1. Load the laminator as illustrated in Fig. 33.

2. The over laminate may be PSA or thermal type.

3. If using thermal type, pay attention to the Poly-

in/Poly-out rule.

4. Run a test material prior to running the actual

image to ensure flat output.

5. Use minimal brake tension to achieve quality

output.

6. Do not web the PSA mount adhesive around the

lower web idler.

Tips for mounting a Decal

1. Use a leader board to set the pull roller pressure

Prior to mounting the image.

2. The image should not exceed the width of the

board by more than 1 in. (2.54 cm) per side.

3. Tack about 1 in. (2.54 cm) of the leading edge

of the decal to the leading edge of the board.

4. When tacking the leading edge, start in the

center and work to the sides.

5. Use a board that exceeds the size of the decal if

inexperienced in the mounting application.

Note: This application can also be performed from

the front operating position. Reference Fig. 31 for

Illustration.

Tips for Thermal Encapsulation

1. Load the laminator as illustrated in Fig. 35

Poly-in film is used for illustration purpose.

2. Refer to section entitled FILM LOADING &

THREADING for Poly-out film.

3. Always use two rolls of film the same width.

4. Use minimal brake tension to achieve flat

output.

5. Increase speed gradually to maintain the

activating temperature required for the laminate

you are using.

6. Length and width of image, ink coverage and

paper type may affect the temperature and speed

recommended in the SPEED/ TEMPERATURE

GUIDE.