Configuration – Banner PVD100 Pallet Sensor User Manual

Page 4

Configuration

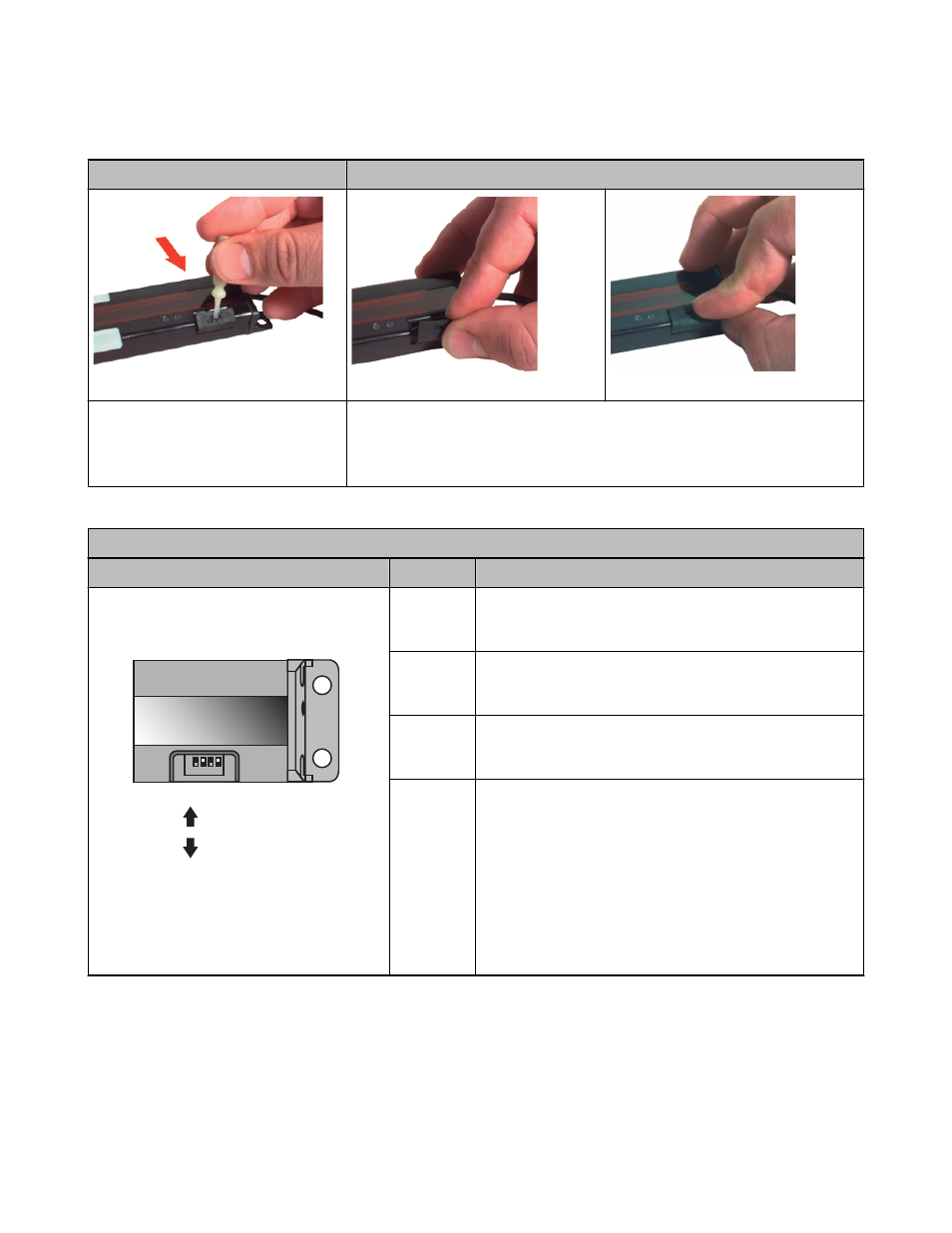

To configure the PVD, set the DIP switches as shown, using the supplied plastic screwdriver to avoid damaging the switches or causing a

short circuit.

Cover Removal

Cover Replacement

Insert a fingernail or small screwdriver into

the slot; apply gentle pressure, angling

away from the sensor lens. The cover will

remain tethered to the sensor housing.

To replace the switch cover, align one edge of the cover with the edge of the sensor

housing opening. Then press the front corners into place.

The switches determine four status operating modes:

PVD Configuration DIP Switch Settings

The factory default setting is ON for all switches

Switch

Condition

1 2 3 4

O

F

F

O

N

ON

OFF

Example Shown:

Switch #1

OFF

Switch #2

ON

Switch #3

OFF

Switch #4

ON

Figure 6. Configuration DIP switch setting posi-

tions

1

ON = PNP output

OFF = NPN output

2

ON = Normally Open

OFF = Normally Closed

3

ON = Job light steady

OFF = Job light flashes

4

Job light control input: Connect the white wire as follows:

PNP Output

ON = Job light ON for +10 to 30V dc (29kΩ input impedance)

OFF = Job light ON for 0 to 1.5V dc/open circuit

NPN Output

ON = Job light ON for +10 to 30V dc/open circuit

OFF = Job light ON for 0 to 1.5V dc (10kΩ input impedance)

PVD Series Parts Verification Sensor

4

www.bannerengineering.com - tel: 763-544-3164

P/N 113230_web

Rev. E