Buried installation – Banner SureCross DX80 Wireless M-GAGE Node User Manual

Page 10

Banner Engineering Corp. • Minneapolis, MN U.S.A

www.bannerengineering.com • Tel: 763.544.3164

10

P/N 131598 rev. F

SureCross™ DX80 M-GAGE™ Node with Integrated Battery

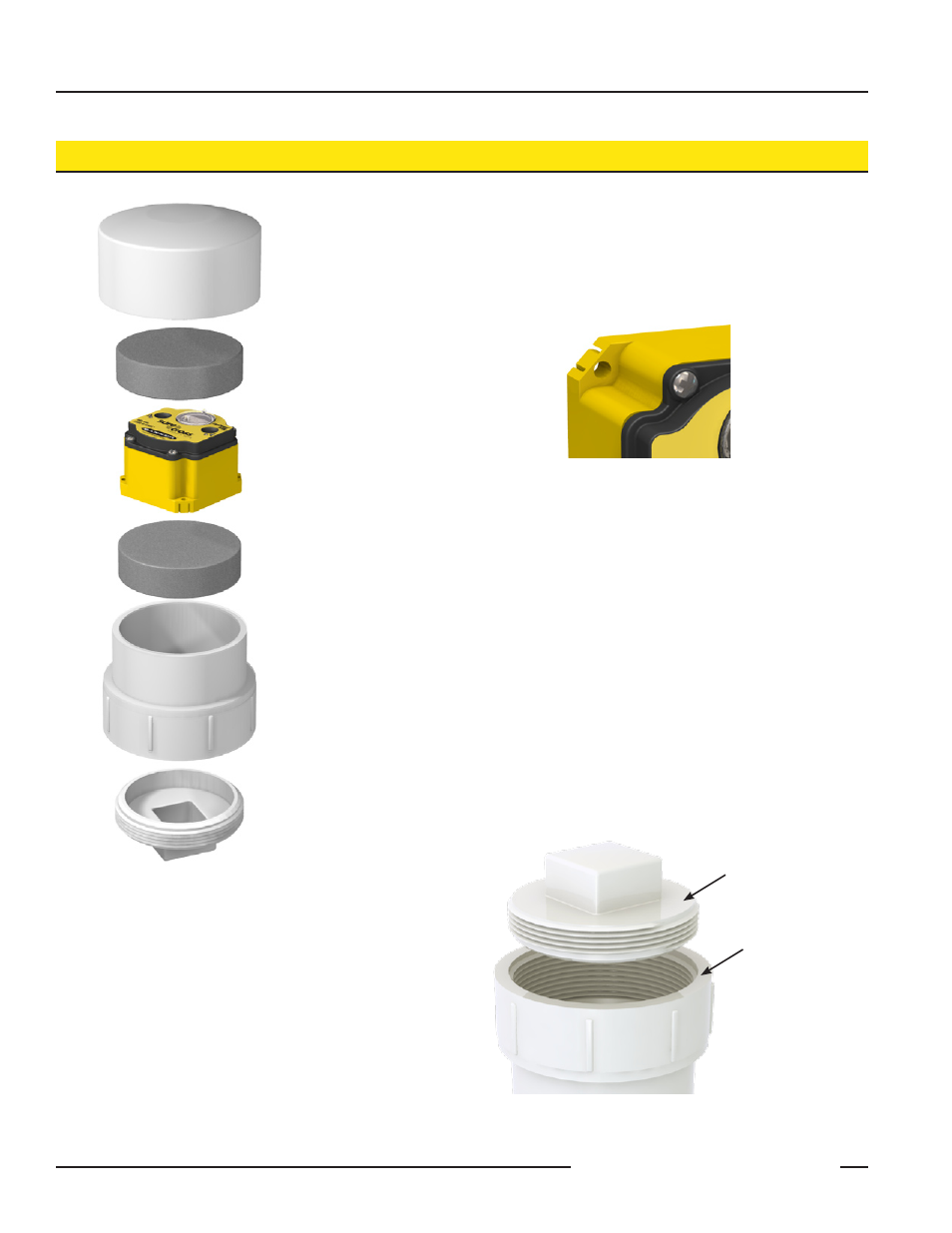

Buried Installation

To protect the M-GAGE in a buried application, Banner Engineering recommends

installing the device within a protective 4” dia PVC enclosure. Form the enclosure

using a cleanout fitting with a thread-out plug and end cap.

To create a waterproof environment for the M-GAGE Node, follow these steps:

1. Cut part of the mounting ears off, as shown in figure 5, to allow the

M-GAGE Node to fit through the cleanout fitting.

Cleanout thread-out

plug, 4” dia PVC

Cleanout fitting, 4” dia

PVC

End cap, 4” dia PVC

Figure 4. Additional items needed but not

shown: 1/2” wide PTFE seal tape, PVC primer,

PVC cement

1 1/4 thick foam

1 1/4 thick foam

2. Coat the joint area between the end cap and cleanout fitting with PVC

primer and PVC cement.

3. Insert the cleanout fitting into the end cap until the fitting comes into full

contact with the end cap.

4. Allow the adhesive to dry for 24 hours.

5. Wrap several layers of PTFE seal tape around the entire threaded edge

of the cleanout plug.

6. Insert a 1” to 1 1/2” thick piece of foam into the end cap.

7. Enable the M-GAGE Node by pressing button 1 for four seconds. LED

1 should flash green to indicate the device is powered up and operat-

ing.

8. Insert the M-GAGE Node into the capsule on top of the first foam piece

as shown in figure 4.

9. Place another foam piece behind the M-GAGE to prevent the device

from moving in the capsule.

10. Place the cleanout plug into position and tighten until the top of the plug

is flush with the surface of the fitting, as shown in figure 6.

11. Bury the capsule in the ground with the plug on the bottom and the end

cap on the top.

Cleanout fitting

Cleanout plug

Figure 6. When sealed, the cleanout plug

should be flush with the surface of the fitting.

Figure 5