Overview, Installation – Banner K80 Pick-to-Light EZ-LIGHT User Manual

Page 4

Overview

The solid-state output interfaces to a system controller, which is pre-programmed for a specific sequence of tasks. Mounted in or near

each bin in an assembler’s work station, the sensor job light signals the assembler which bins contain items to be picked in a given

operation and in what order they should be picked.

As the assembler takes a part in sequence, the sensor senses that the part was removed and it sends an output signal to the controller.

The controller then verifies if the correct part was taken and may respond by turning that job light OFF, activating the job light of the next

bin in the sequence.

If multiple parts are to be removed from one bin, the job light may remain ON until the appropriate number of signals is returned to the

controller. If an incorrect part is selected, the control system may be wired to signal an alarm for the assembler and/or a supervisor, or it

may be programmed to interpret the action as a call for parts.

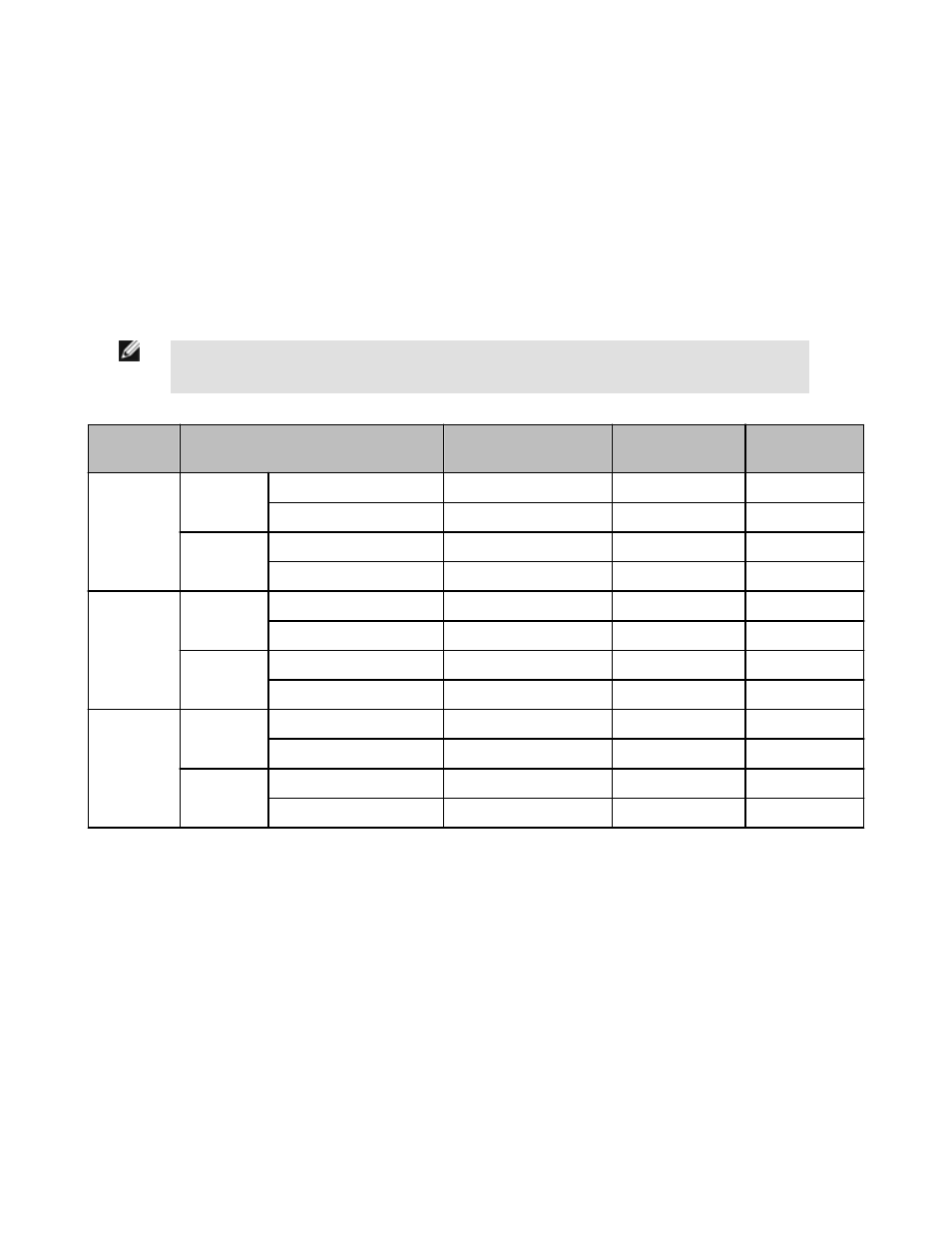

Indicator and Output Behavior

NOTE: "D," "C," and "E" Series models as referenced in the table pertain to a part of the product model num-

ber, immediately preceding the Q designation.

Models

Sensor Conditions

Job Light

Alternate Indicator

Output Signal

Status

Standard

(D-Series)

Job input ac-

tive

Hand/pick absent

ON Green

—

OFF

Hand/pick present

ON Green

—

ON

No job input

Hand/pick absent

—

OFF

Hand/pick present

—

ON

C-Series

Job input ac-

tive

Hand/pick absent

ON Green

—

OFF

Hand/pick present

—

ON Red

ON

No job input

Hand/pick absent

OFF

OFF

OFF

Hand/pick present

—

ON Red

ON

E-Series

Job input ac-

tive

Hand/pick absent

ON Green

—

OFF

Hand/pick present

ON Green

—

ON

No job input

Hand/pick absent

OFF

—

OFF

Hand/pick present

—

ON Red

ON

Installation

For push-button models, install the sensor at such a height and in a location that will be easy for the user and/or supervisor to see the

indicator and will be comfortable for the user to press the push-button.

For other models, install the sensor in a location that will be comfortable for the user to break the beam when reaching for the required

part. When multiple sensors will be located in close proximity, to monitor multiple bins for example, mount all the sensors in a similar

sensing position (all mounted at the tops of the bins and pointing down, for example). This may reduce potential optical crosstalk, where

one sensor detects another sensor’s beam.

EZ-LIGHT® K50 and K80 Series Pick-to-Light Sensors

4

www.bannerengineering.com - tel: 763-544-3164

P/N 126441_web

Rev.G