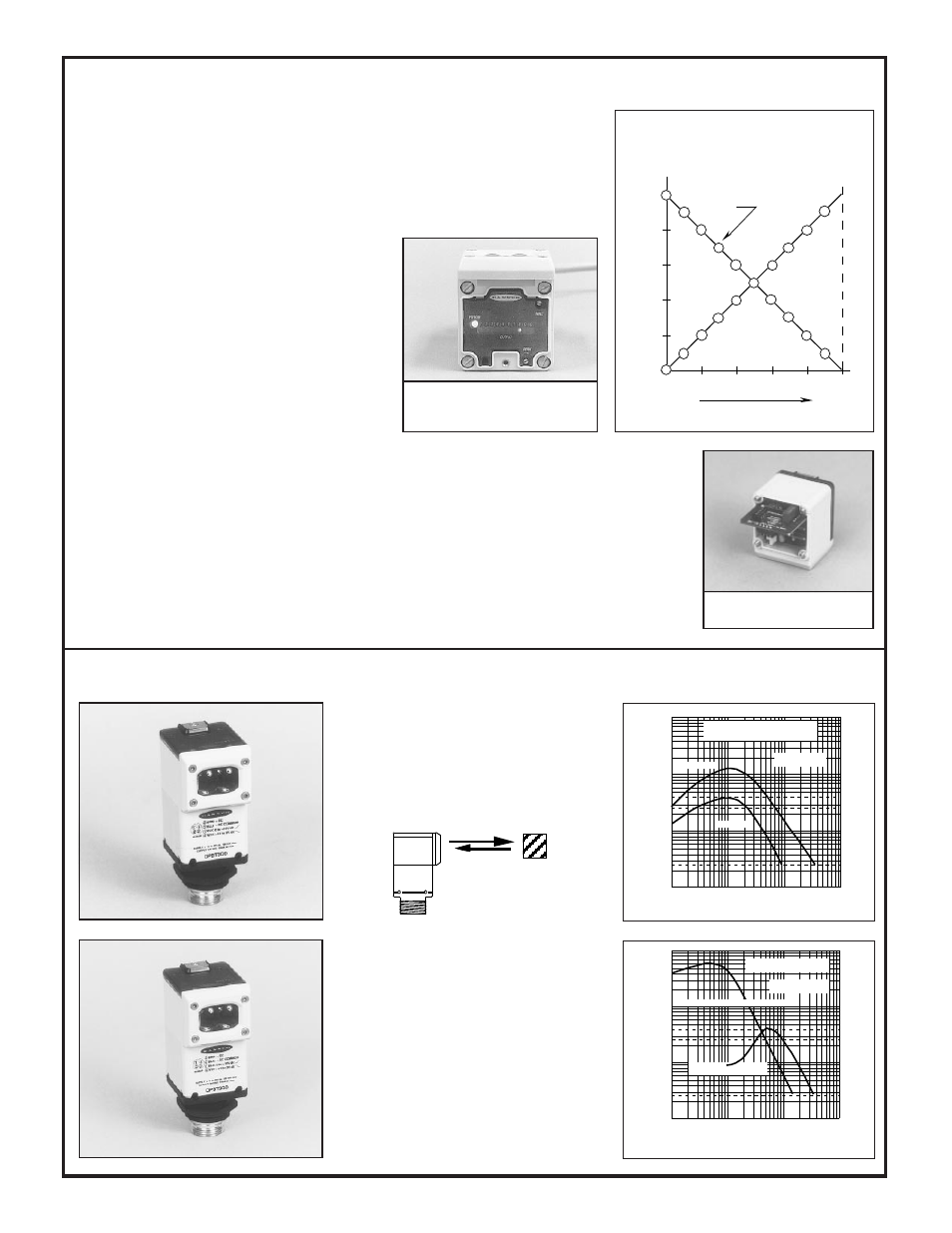

Diffuse (proximity) mode: models oasbd and oasbdx, Oasbdx, Adjustment procedure – Banner OMNI-BEAM Series User Manual

Page 3: Analog omni-beam sensors, 3model, Oasbd, Model

3

Model

OASBDX

Beam: infrared, 880nm

Maximum Response Range

(at maximum NULL and maximum SPAN):

12 feet (3,7m)

1) Before adjusting the NULL and SPAN, slide the OALM board out from the base of the sensor

head and set the output response time at the DIP switch. Refer to the photo (below right) and the

information printed on the OALM board. Switch settings are given in the Specifications section

(page 2, top). Longer time settings are useful for "smoothing" sensor response. Slide the OALM

board back into the sensor head.

2) Begin with the sensor mounted at the sensing position and connected, per the hookup diagrams

on page 2, for the desired output (inverting or non-inverting). The most precise adjustment is attained

by using a voltmeter connected to monitor the desired

output, as shown in the hookup diagrams. Present the

"lightest" expected sensing condition to the sensor (the

condition that results in the most light seen by the receiver).

Next, perform either step #3 or step #4.

3) To adjust the inverting output: monitor the voltage

on the black wire. Adjust the NULL control to the point

where the output just reaches 0 volts*. Then present to the

sensor the "darkest" expected sensing condition (the condi-

tion that results in least light seen by the receiver), and adjust

the SPAN control to just reach 10 volts output.

4) To adjust the non-inverting output: monitor the

voltage on the white wire. Adjust the NULL control to the

point where the output just reaches 10 volts. Then present

to the sensor the "darkest" expected sensing condition (the condition that results in the least light seen by the receiver),

and adjust the SPAN control to just reach 0 volts* output.

As can be seen from the graph (above, right), the slopes of the two 0-to-10V outputs are mirror-images of each other,

and the plots intersect at 5 volts output. When the 0 and 10 volt points of one output have been properly set, the other

output will track very close to the predicted values.

Other voltage ranges may be used. The practicality of doing so depends upon conditions specific to each individual

application. Substitute the lower voltage for "0 volts", and the higher voltage for "10 volts" in the preceding

adjustment instructions. When a range of other than 0 to 10 volts is used the NULL and SPAN controls will no longer

be non-interactive. If you require further assistance, contact your Banner field sales representative or a factory

applications engineer.

The OALM analog board slides

easily in and out of the sensor head.

Diffuse (Proximity) Mode: models OASBD and OASBDX

1

.1

DISTANCE

10

100

Range based on 90%

reflectance white test card

1 IN

OASBDX

10 IN

100 IN

100 IN

E

X

C

E

S

S

G

A

I

N

I

Max. NULL (upper DISTANCE scale)

4

2.7

.25

Min. NULL

(lower DISTANCE scale)

.1 IN

1 IN

10 IN

1000 IN

1

.1

DISTANCE

10

100

.1 IN

1 IN

10 IN

100 IN

Range based on 90%

reflectance white test card

OASBD

E

X

C

E

S

S

G

A

I

N

I

4

2.7

.25

Max. NULL

Min. NULL

0

2

4

6

8

10

Output (V dc)

Output Indicator

LEDs

Non-inverting output

3

Inverting output

Darkest

condition

Lightest

condition

Light signal strength

1

5

10

2

3

4

6

7

8

9

1

2

3

4

6

7

8

9

10

0

0%

60%

40%

100%

20%

80%

Adjustment Procedure,

Analog OMNI-BEAM Sensors

Top view of Analog OMNI-BEAM show-

ing the NULL and SPAN controls and the

moving-dot LED display.

The Analog OMNI-BEAM's moving-dot

LED array indicates approximate output

voltage and relative light signal strength.

Model

OASBD

Beam: infrared, 880nm

Maximum Response Range

(at maximum NULL and maximum SPAN):

36 inches (0,9m)

NOTE: The target used to plot the OSBD

and OSBDX response curves is a 90% re-

flectance white test card which measures 16

inches by 20 inches (400mm x 500mm).

Actual sensor response must consider both

the relative surface reflectivity and the ac-

tual reflective surface area of any target.

OBJECT

*Adjust the pot for minimum voltage near 0 volts dc. Voltmeter may not indicate exactly 0 volts.