Banner OMNI-BEAM Series User Manual

Analog omni-beam, Sensors, With voltage sourcing outputs

•

•

•

•

•

•

Analog OMNI-BEAM

™

Sensors

with Voltage Sourcing Outputs

Proven OMNI-BEAM optical performance in sensors

with analog voltage sourcing outputs

Ideal for applications requiring a continuously variable

control voltage that is either directly or inversely related

to a sensing parameter; "mirror-image" outputs

Analog output is ripple-free and temperature-stable

Non-interactive NULL and SPAN controls for ease of

adjustment

Built-in 10-element LED display indicates output voltage

Models available for diffuse, convergent, and fiber optic

sensing modes, and for ac or dc supply voltages

Banner Analog OMNI-BEAM™ Sensors combine the proven optical

performance of standard OMNI-BEAM™ sensors with a 0 to 10V dc

or 10 to 0V dc sourcing analog output power block to produce a highly

versatile and practical analog photoelectric control. Analog photo-

electric sensors are especially useful in applications such as process

control, where it is necessary to monitor an object's position or size to

produce a variable control voltage for an analog device such as a motor

speed control. Analog photoelectric sensors are also used to monitor

the optical reflectivity or optical clarity of materials.

Analog OMNI-BEAM sensors provide a variable dc voltage output

that is either directly related ("non-inverting" output) or inversely

related ("inverting" output) to the strength of the received light signal.

When properly adjusted, the two analog outputs are mirror-images of

each other, with their output voltage plots intersecting at 5 volts (see

page 3). Each sensor has multi-turn NULL and SPAN controls to set

the minimum and maximum limits of the sensor's sourcing voltage

outputs. An innovative, custom-designed analog sensor circuit design

allows NULL and SPAN to be adjusted without interaction, greatly

simplifying the setup adjustment procedure. A convenient 10-element

moving-dot LED array gives a visual indication of relative light signal

change and power block voltage output to within the nearest volt.

Analog OMNI-BEAM sensors consist of two basic "building blocks":

a sensor head and a power block. The sensor head contains optical

components, an analog amplifier, NULL and SPAN adjustment con-

trols, and LED indicator array circuitry. Sensor heads are available for

diffuse, convergent, and fiber optic sensing modes. Fiber optic mode

models include infrared and visible-light glass fiber optic models, and

a visible-light plastic fiber optic model. The power block contains

power supply and analog voltage output circuits, and is offered in

three basic models: model OPBT3 (for +15 to 30V dc), model OPBA3

(for 105 to 130V ac), and model OPBB3 (for 210 to 250V ac). Power

block models are listed in the table on page 2.

Power blocks are available with either an attached 6-foot PVC-

covered cable or an integral QD (Quick-disconnect) connector. Twelve-

foot lengths of mating minifast

™

quick-disconnect cable are sold

separately.

To order an Analog OMNI-BEAM sensor, specify the following:

1) a sensor head model (from pages 3, 4, and 5), and

2) a power block model (from page 2).

The sensor head module and the power block module

are sold separately.

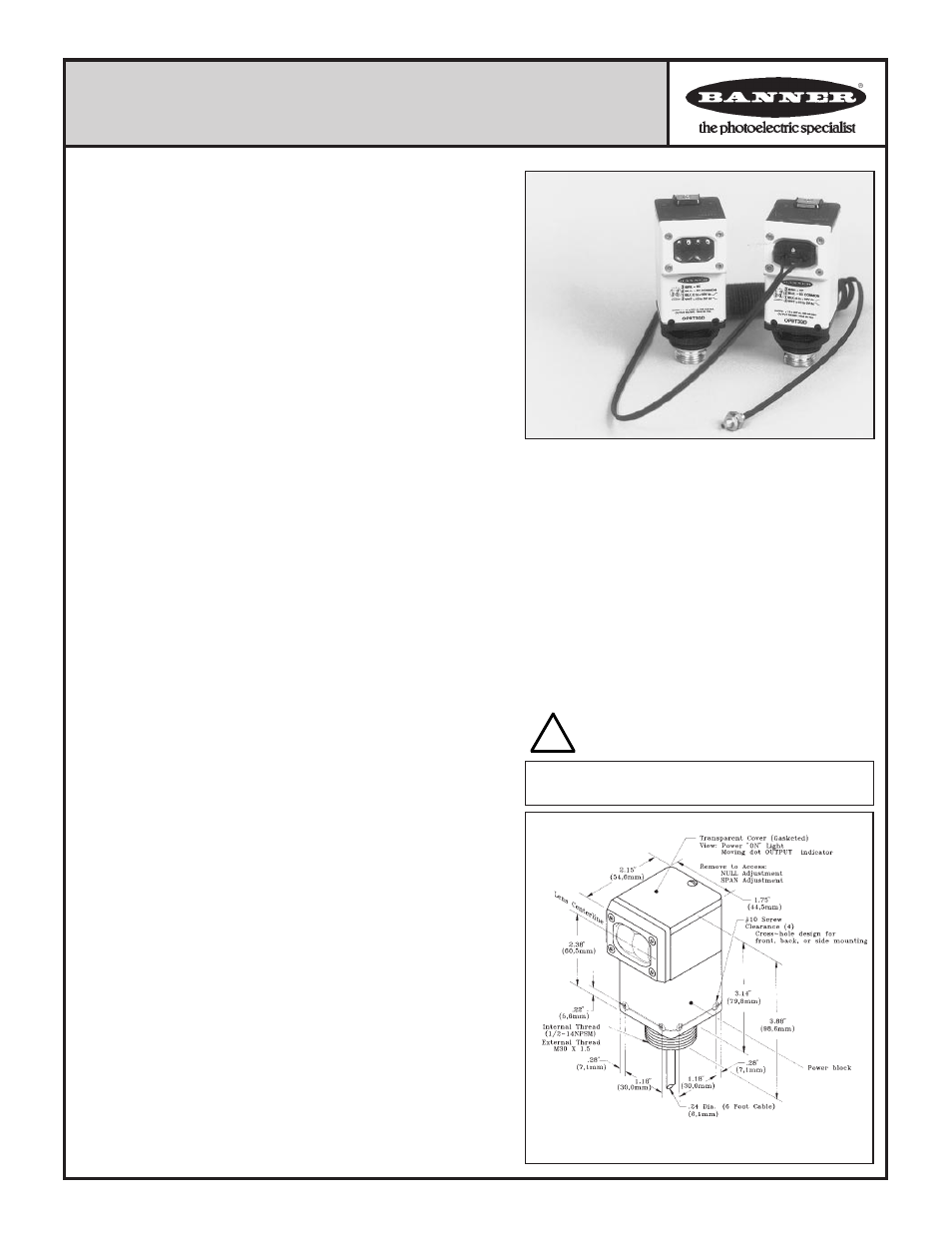

Shown are models

OASBD (l) and

OASBFP with

coiled plastic

fiber optic

assembly (r);

shown with

OPBT3QD

QD-style dc

power blocks.

Dimensions

P/N 03579A4C

Printed in USA

A comprehensive introduction to the theory and use of

photoelectric analog sensors begins on page 5.

Power requirements:

+15 to 30V dc, OPBT3 power block models

105 to 130V ac (50/60Hz), OPBA3 power block models

210 to 250V ac (50/60Hz), OPBB3 power block models

Sensing range: see individual sensor head specifications

Output:

The output is an analog voltage that is related to the intensity of the

light reaching the receiver.

The relationship between the 0 to 10V dc analog output voltage and

the received light signal intensity is determined by the wiring

configuration, and may be either direct or inverse.

Output capacity 10mA, maximum. Both outputs may be used

simultaneously, but the maximum total load may not exceed

10mA. Outputs are protected against short-circuit and overload.

Specifications

(Specifications are continued on page 2)

Please read Personnel Safety WARNING, page 8.

!