Bendix Commercial Vehicle Systems C-300N HYDRAULIC POWER STEERING1/99 User Manual

Page 8

8

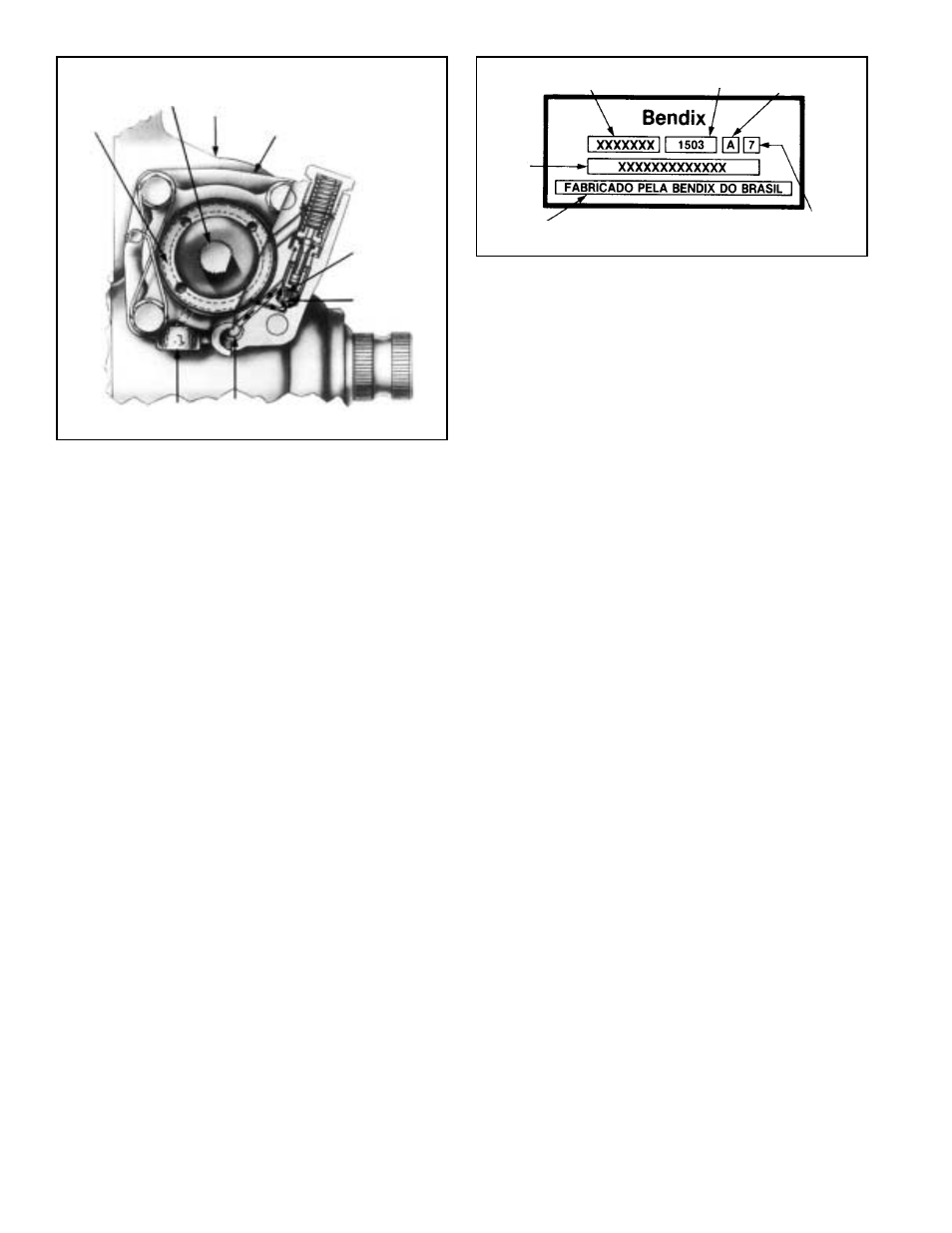

BYPASS VALVE OPERATION

The optional bypass valve is located adjacent to the pressure

relief valve in the valve body.

When it is necessary to steer the vehicle without the power

steering pump in operation, the bypass valve permits oil to

flow from the return to the supply passages within the

steering gear. As the power piston moves inside the housing,

oil displaced from one side is transferred to the other through

the bypass valve thus preventing reservoir flooding and

cavitation in the pressure line. Figure 9

POWER STEERING GEAR IDENTIFICATION

A nameplate is attached to the exterior of the housing

generally on one of the mounting lugs. The information found

on the name tag is illustrated

PREVENTIVE MAINTENANCE

POWER STEERING OIL

It is important that an approved oil be used to ensure proper

operation of the power steering unit. The vehicle

manufacturers recommendations should be adhered to.

Once an oil type is in use, it should never be mixed with any

other type. If it should become necessary to change types

of oil, the entire system must be drained following the

procedure below.

DRAINING AND FILLING THE SYSTEM

1. Lift the front axle sufficiently to raise the wheels clear of

the ground.

2. Remove the drain plug (54) and seal washer(53) or

disconnect the return line at the valve body outlet port.

(The outlet port is identified by the arrow which flows out

of the gear.) Turn the steering wheel to the left as far as

it will go. Run the engine for 10 seconds at the most

until the oil is drained from the reservoir and pump. Switch

off the engine and turn the steering wheel backwards

and forwards from full lock to full lock until all the oil is

drained out.

3. Clean the outside of the reservoir. Remove and replace

the old filter element.

4. Fill reservoir full of oil.

5. Turn the engine over with the starter motor. (Must be

done in a manner that the engine does not start.) Add oil

as the level drops to avoid air being drawn into the

system.

6. When the oil level reaches the full mark on the dipstick,

start the engine and turn the steering wheel slowly from

side to side until air bubbles cease to appear in the

reservoir. Refill reservoir to full mark on the dipstick.

7. The oil level should be checked every 2,000 miles. The

correct level is between the minimum and maximum level

marks on the dipstick with the engine stopped.

OIL CHANGE INTERVALS

It is recommended that the oil be changed at 40,000 mile

intervals and at the time of rebuild. Beyond its function as

the media for transmitting power, the oil also serves to

lubricate and dissipate heat. Carefully clean, inspect, and

replace if necessary all filter elements in the pump system

including vents and breathers.

OUTPUT SHAFT SECTOR TEETH

ADJUSTMENT

The gear lash or preload between the piston teeth and sector

gear should not require attention in normal service, however

a provision for adjustment is provided.

Adjustment requires that the steering gear be drained and

the pitman arm and input shaft be disconnected from the

vehicle. The adjustment procedure is described at the end

of the assembly section of this manual.

POWER STEERING GEAR NAMEPLATE INFORMATION

SERIAL NUMBER

BENDIX ASSEMBLY

PART NUMBER

MONTH ASSEMBLED

(A = JAN., ETC.

VEHICLE

MFGR

PART

NUMBER

LOCATION OF

MANUFACTURE

YEAR ASSEMBLED

(LAST DIGIT)

FIGURE 9 - BYPASS VALVE OPERATION

INPUT

SHAFT

OIL

RETURN

CHANNEL

POWER

STEERING

GEAR

HOUSING VALVE

BODY

SPRING

BYPASS

VALVE

OIL SUPPLY

PORT

OIL RETURN

PORT