Bendix Commercial Vehicle Systems COMPACT 500 9/87 User Manual

Page 4

4

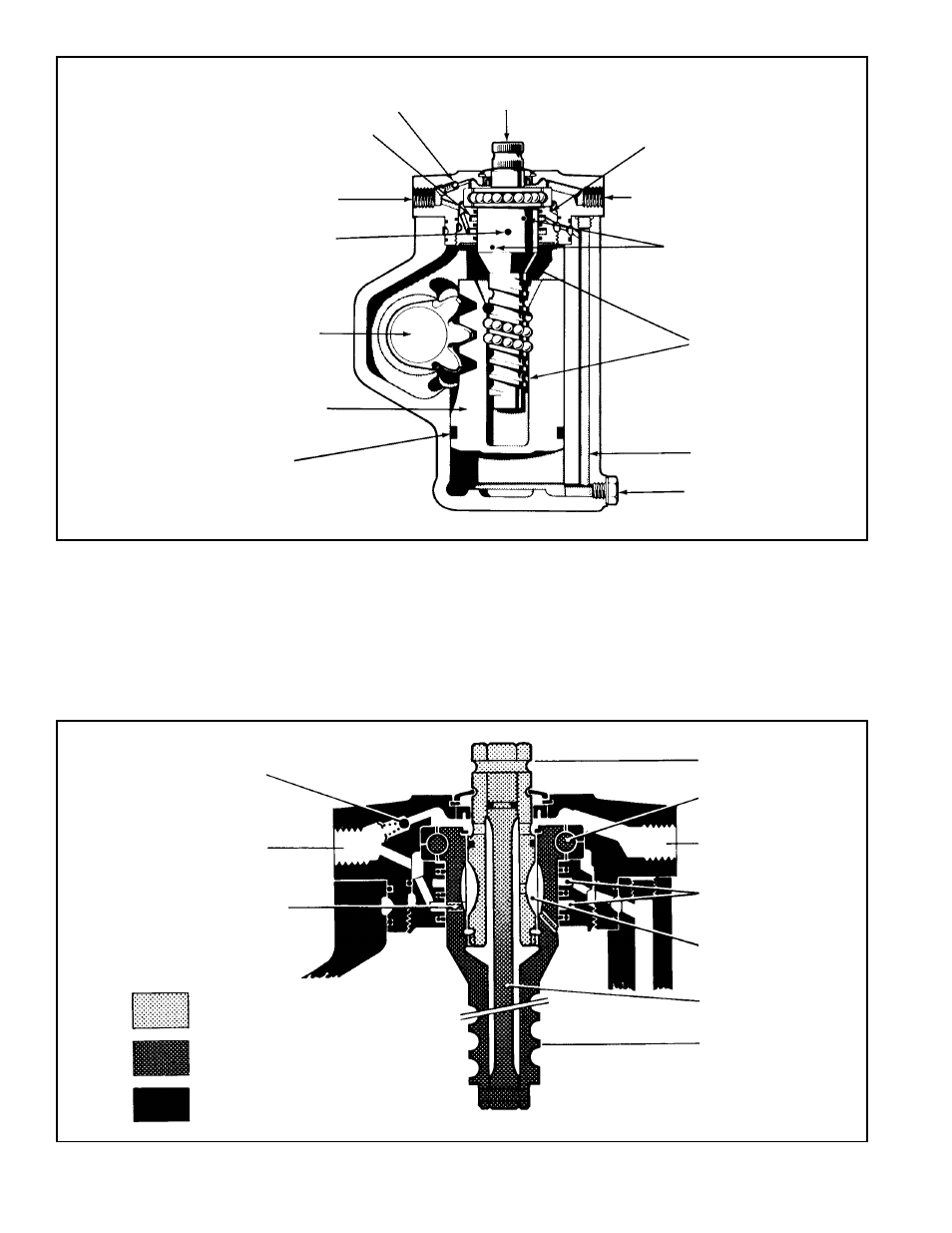

FIGURE 2

SEAL AND

GLIDE RINGS

SPINDLE ASSEMBLY W/

ROTARY VALVE (BALL

SCREW ASSEMBLY)

DELIVERY FROM

ROTARY VALVE

OIL OUT

INPUT

SHAFT

VALVE NUT

BY PASS

VALVE

CIRCULAR

GROOVES

OIL IN

ROTARY

VALVE

SUPPLY

OUTPUT

SHAFT

PISTON

OIL PASSAGE

DRAIN PLUG

FIGURE 3

MECHANICAL-

HYDRAULIC PARTS

CIRCULAR

GROOVES

OIL OUTLET

INPUT SHAFT

BEARING

BY PASS

VALVE

LONGITUDINAL

GROOVES

OIL INLET

PARTS WITH NO

MOVEMENT

MECHANICAL

MOVEMENT PARTS

CONNECTING POLE

TORSION BAR

BALL SCREW

bar results in the input shaft rotating slightly in advance of

the ball screw. The six pairs of grooves that form the rotary

control valve are displaced from their neutral flow position.

As steering effort increases so does the amount of

displacement. Depending on the direction steered, the groove

displacement of the input shaft directs hydraulic oil through

the appropriate drilled passages in the ball screw to one

side or the other of the piston. Hydraulic pressure acting

upon the piston surface eliminates much of the pistons

resistance to movement. Spring force exerted by the torsion

bar causes the ball screw to rotate as piston resistance is

removed. As the ball screw rotates, the relative groove