Bendix Commercial Vehicle Systems COMPACT 500 9/87 User Manual

Page 17

17

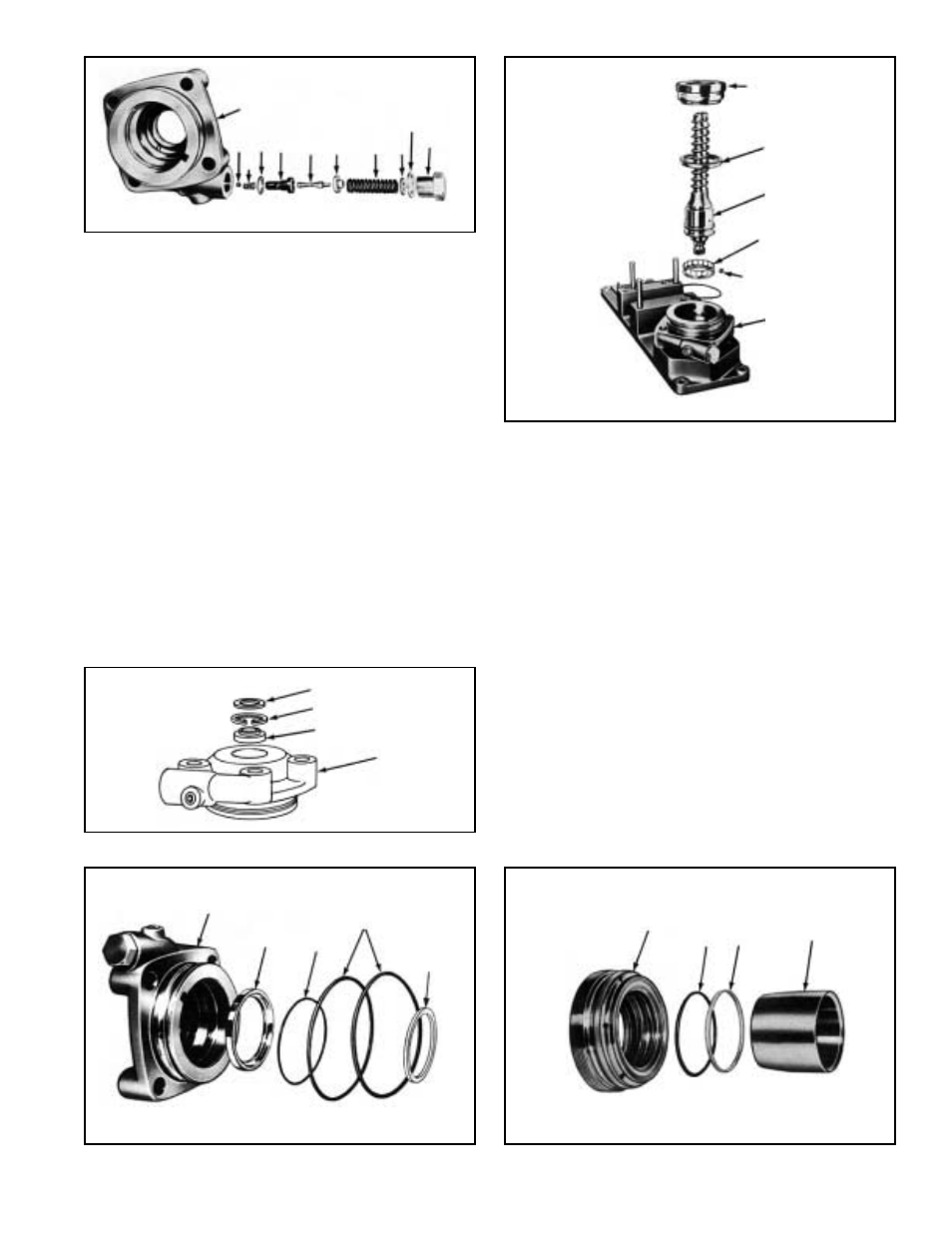

FIGURE 33

VALVE BODY (REFER TO FIGURE 30)

1. Place the valve body(16) in a vise and lightly tighten on

the cast surface. Install the ball(12), spring(11) valve

seat(9) and the copper/seal washer(10). Tighten with

an appropriate screwdriver to a torque of 200 in. lbs.

(See Figure 30)

NOTE: A new copper washer(4) must be used to assure

correct sealing.

Install the relief valve rod(8), the guide(7) and the spring(6).

Place the copper seal washer(4) onto the plug(3) with

the corresponding adjusting shims(5) and tighten with

26 mm. torque wrench. Torque to 66-74 ft. lbs.

2. Install the seal(15), snap ring(14), and dust seal(13) into

valve body(16). (See Figure 31)

3. Using tool number 297647, install the inner ball race(28)

(in the event it was removed), into the bottom of valve

body and install internal O-Ring(17) and the two external

O-Rings(19). (See Figure 32). Install nylon seal(18) in

the internal threaded portion of the valve body(16). (See

Figure 7)

SPINDLE ASSEMBLY

4. Install the cage(30) on the input shaft end of the

spindle(34). Install the outer ball race(28) and using a

lithium base general purpose grease (Ford Chassis

grease ESA-M1C75-B) to hold them in place insert the

17 new balls(29) comprising the bearing. Insert the

assembly into the valve body. (See Figure 33)

Remove from the valve nut(33), the three teflon glide seal

rings(32) and the three O-Rings(31) and install new ones.

When they are in their respective grooves, insert the

tool 297676 to seat them. (See Figure 34)

NOTE: Make certain the O-rings and glide rings are

in their proper grooves. (Refer to Figure 5) An oil

channel separates each ring.

30

34

28

33

29

16

FIGURE 32

16

28

17

19

18

FIGURE 34

33

31

32

297676

FIGURE 30

11

16

12 10 9

8

7

6

5

4

3

FIGURE 31

13

14

15

16