Rockwell Automation Safety Function: Hinge Switch User Manual

Page 15

Safety Function: Hinge Switch

15

Rockwell Automation Publication SAFETY-AT096A-EN-P – November 2013

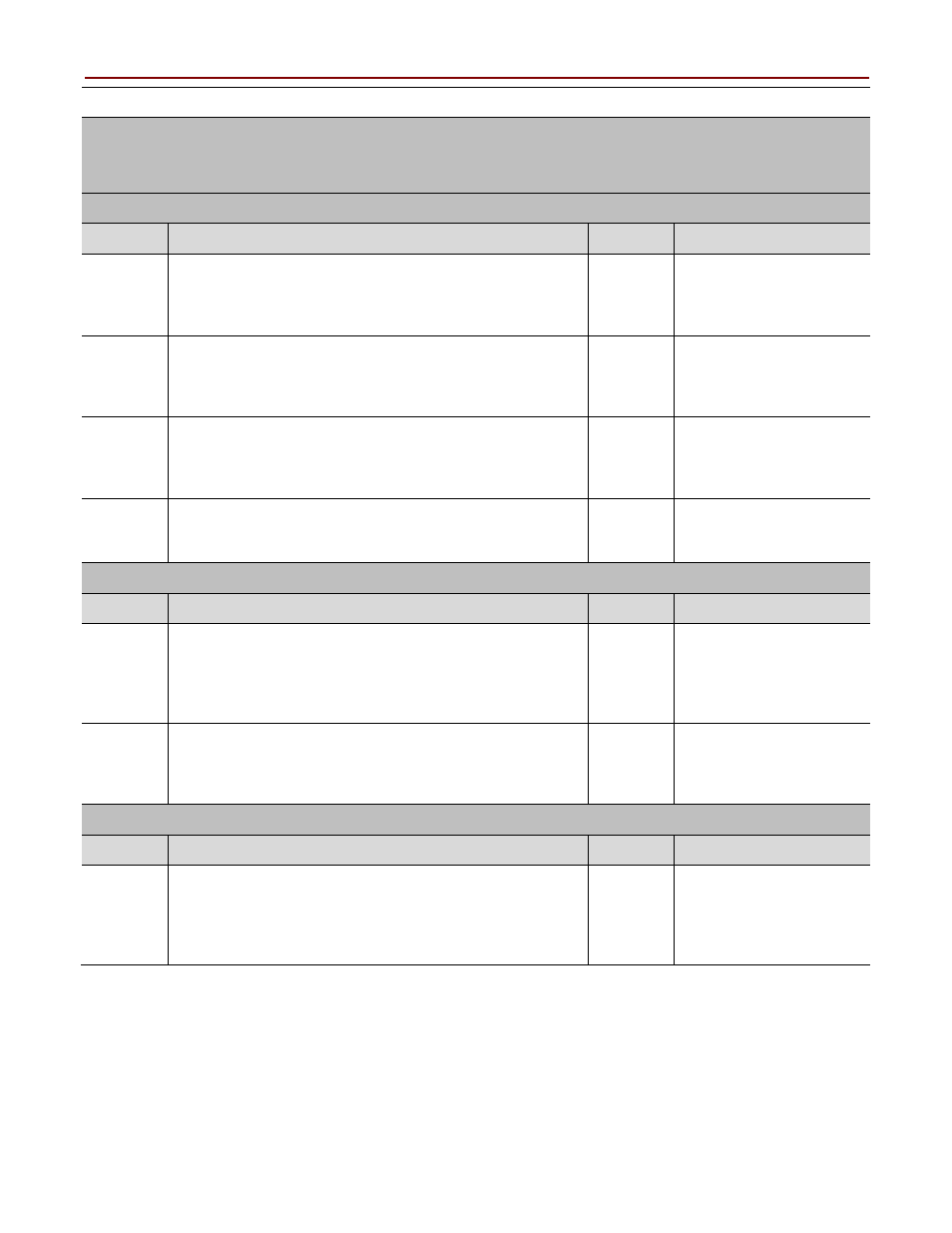

GSR Emergency Stop Safety Function Verification and Validation Checklist (continued)

Abnormal Operation Validation

The safety relay system properly responds to all foreseeable faults with corresponding

diagnostics.

E-stop Input Tests

Test Step

Validation

Pass/Fail Changes/Modification

While the system is running, remove the channel 1 wire

from the safety relay. Both contactors de-energize. Verify

proper machine-status indication and safety-relay status

indication. Repeat for channel 2.

While the system is running, short channel 1 of the safety

relay to 24V DC. Both contactors de-energize. Verify proper

machine-status indication and safety-relay status indication.

Repeat for channel 2.

While the system is running, short channel 1 of the safety

relay to 0V DC. Both contactors de-energize. Verify proper

machine-status indication and safety-relay status indication.

Repeat for channel 2.

While the system is running, short channels 1 and 2 of the

safety relay. Both contactors de-energize. Verify proper

machine-status indication and safety-relay status indication.

GSR Logic Solver Tests

Test Step

Verification and Validation

Pass/Fail Changes/Modification

While the system is running, remove the single wire safety

connection between two adjoining safety relays in the

system. All contactors de-energize. Verify proper

machine-status indication and safety-relay status indication.

Repeat for all safety connections.

While the system is running, turn the logic rotary switch on

the safety relay. All contactors remain energized. Verify

proper machine-status indication and safety-relay status

indication. Repeat for all safety relays in the system.

Safety Contactor Output Tests

Test Step

Verification and Validation

Pass/Fail Changes/Modification

While the system is running, remove the contactor feedback

from the safety relay. All contactors remain energized.

Initiate a Stop command followed by a Reset command.

The relay does not restart or reset. Verify proper

machine-status indication and safety-relay status indication.