Required parts, Replacing encoders, Preparing for installation – Rockwell Automation HPK-Series Motor Encoder Replacement Installation Instructions User Manual

Page 5

HPK-Series Motor Encoder Replacement Kit 5

Rockwell Automation Publication HPK-IN002C-EN-P - May 2012

Required Parts

To install the HPK-Series Motor Encoder Replacement Kit, you should plan to provide the

following parts. Where possible, reuse screws and other hardware.

•

Fixing screws

•

Electrical tape

Replacing Encoders

Review these sections to become familiar with the steps before you begin to replace your encoder.

Preparing for Installation

Always use equipment and installation practices that promote electromagnetic compatibility

(EMC) and safety. This requires that both the encoder housing and the encoder connectors are

grounded at the motor frame. A metallic connector housing provides the encoder cable with a

physical opening and electrical shielding from the motor and the drive interface cable.

•

Secure the spring mounting plate, on which the encoder is mounted, to the motor frame.

•

Attach the connector housing to the fan shroud or another metal component on the

HPK motor with the four mounting screws.

These connections provide a secure mechanical mount and an electrical ground with the motor

frame.

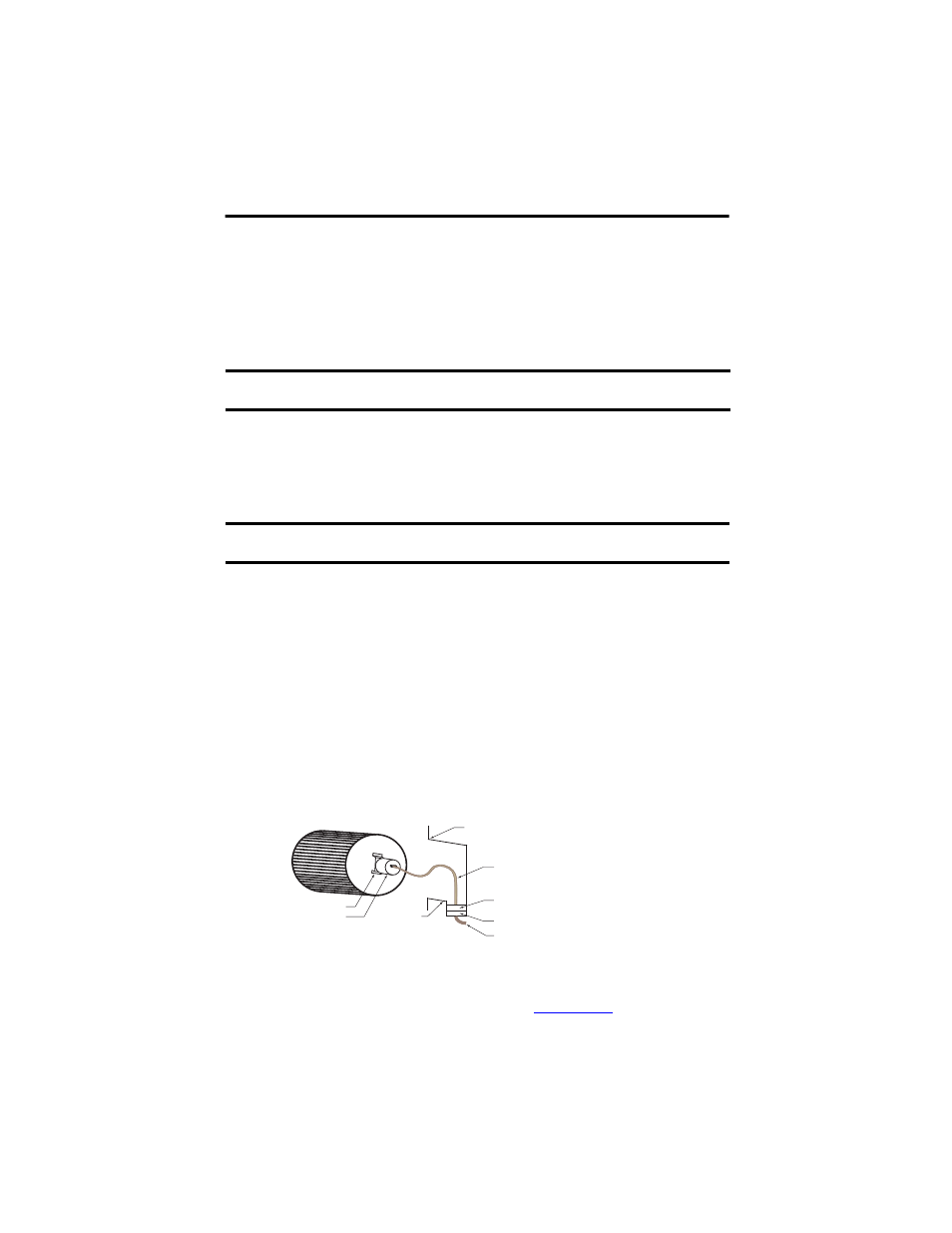

HPK-Series Encoder Replacement Kit Overview

Use high-frequency (HF) bonding techniques to connect the encoder, feedback connector,

motor housing, and machine frame. HF bonding techniques creates a low-impedance return

path for high-frequency (HF) energy and reduce electrical noise. Refer to the System Design for

Control of Electrical Noise Reference Manual, publicatio

, to better understand

the concept of electrical noise reduction.

IMPORTANT

Reuse existing parts, such as screws and other hardware.

Always store parts as you remove the encoder.

IMPORTANT

One of two possible versions of the encoder is installed on your HPK motor.

Use the removal instructions appropriate for the encoder installed on your HPK motor.

Fan Housing or Metal Shroud

Shielded Encoder Cable

Connector Housing (4 mounting screws)

Feedback Connector

Feedback Cable from Drive

Encoder Housing

Spring Mounting Plate

Fan Housing

or Metal Shroud