Blower wiring diagrams, Bearing inspection, Periodic lubrication – Rockwell Automation HPK-Series Asynchronous Servo Motor User Manual

Page 14: Grease and repack bearings

14 HPK-Series Asynchronous Servo Motors

Publication HPK-IN001C-EN-P - June 2010

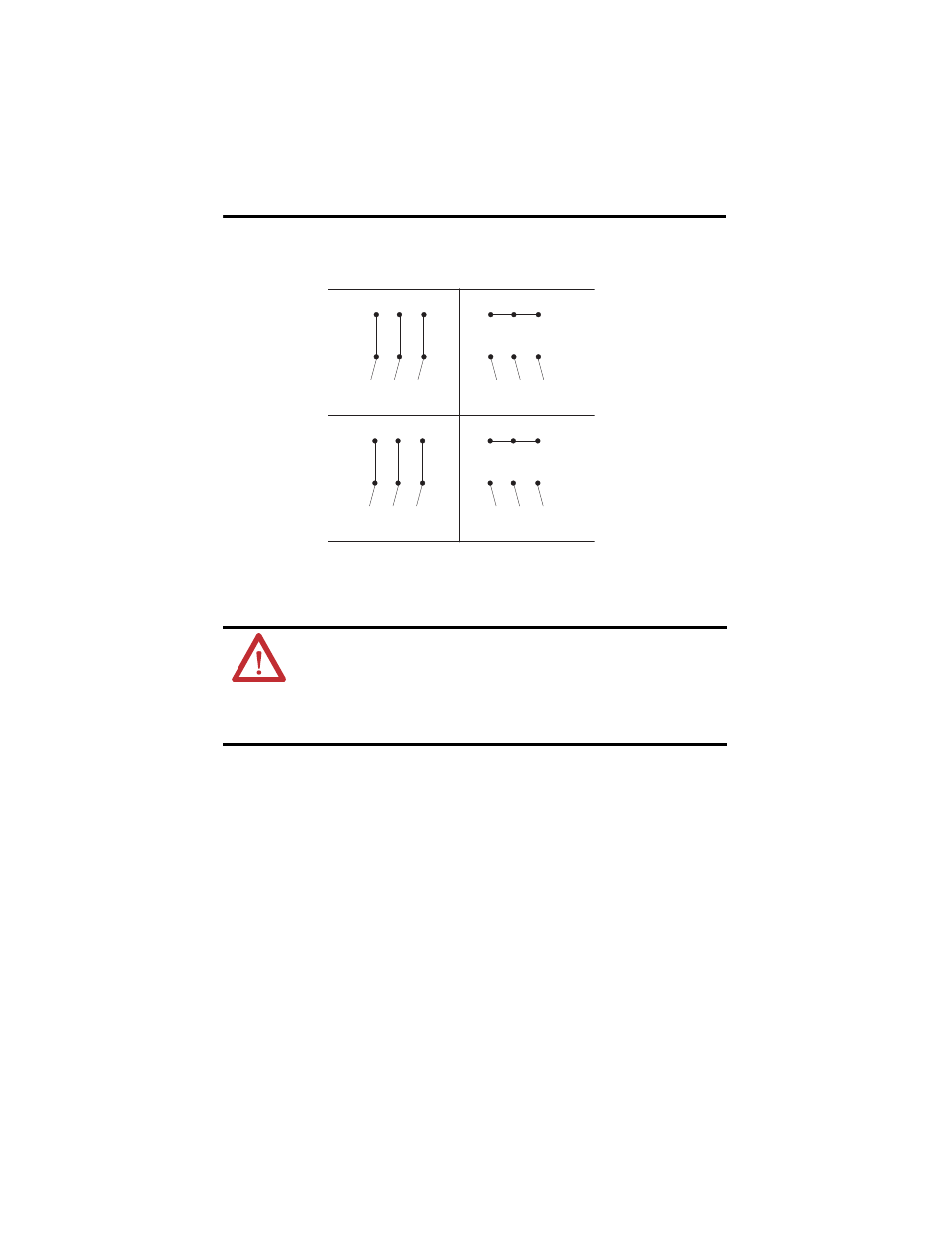

Blower Wiring Diagrams

11.

Attach the feedback cable to the motor as follows:

a. Carefully align the feedback cable connector with the respective motor connector.

b. The flat surface with logo on each connector should align. Do not apply excessive

force when mating the cable and motor connectors. If the connectors do not go

together with light hand force, realign and try again.

c. Fully seat the feedback connector by hand tightening the knurled collar five to six

turns until resistance is felt.

12.

Perform the Troubleshooting and Maintenance procedures listed below that are

appropriate to your installation.

•

Bearing Inspection

•

Periodic Lubrication

•

Grease and Repack Bearings

•

Shaft Key Removal and Installation

ATTENTION: Keyed connectors must be properly aligned and hand-tightened

the recommended number of turns.

Improper connector alignment is indicated by the need for excessive force,

such as the use of tools, to fully seat connectors.

Failure to observe these safety procedures could result in damage to the motor,

cables, and connector components.

DELTA

T4

T6

T5

T2

T1

T3

L2

L1

L3

Low Volts Line

STAR

T4

T6

T5

T2

T1

T3

L2

L1

L3

High Volts Line

U2

W2

V2

V1

U1

W1

L2

L1

L3

Low Volts Line

U2

W2

V2

V1

U1

W1

L2

L1

L3

High Volts Line

U1 = Black

U2 = Green

V1 = Blue

V2 = White

W1 = Brown

W2 = Yellow