Rockwell Automation LC-Series Linear Motor User Manual

Page 24

Item Number 814036 - Rev C

2-18 Installation

9. Position the slide over the complete sections and continue aligning the

remainder of the plates.

10. If the area where the magnet plates are to be installed does not allow you

to use a straight edge describes above, an alternate method of aligning

plates can be done. Space the plate by using a 0.020 plastic shim between

the magnet plates, tighten the bolts, and then remove the shim.

11. Once all the alignment is completed, torque all bolts to values listed in

the tables.When considering torque values for mounting hardware, take

into account the magnet plate, mounting surface and mounting

hardware. Per Table 2.N secure all assemblies in place using all

mounting holes.

ATTENTION

!

Remove alignment tool and make certain all magnet plate

mounting hardware is flush or below magnet surface to

prevent damage to the coil.

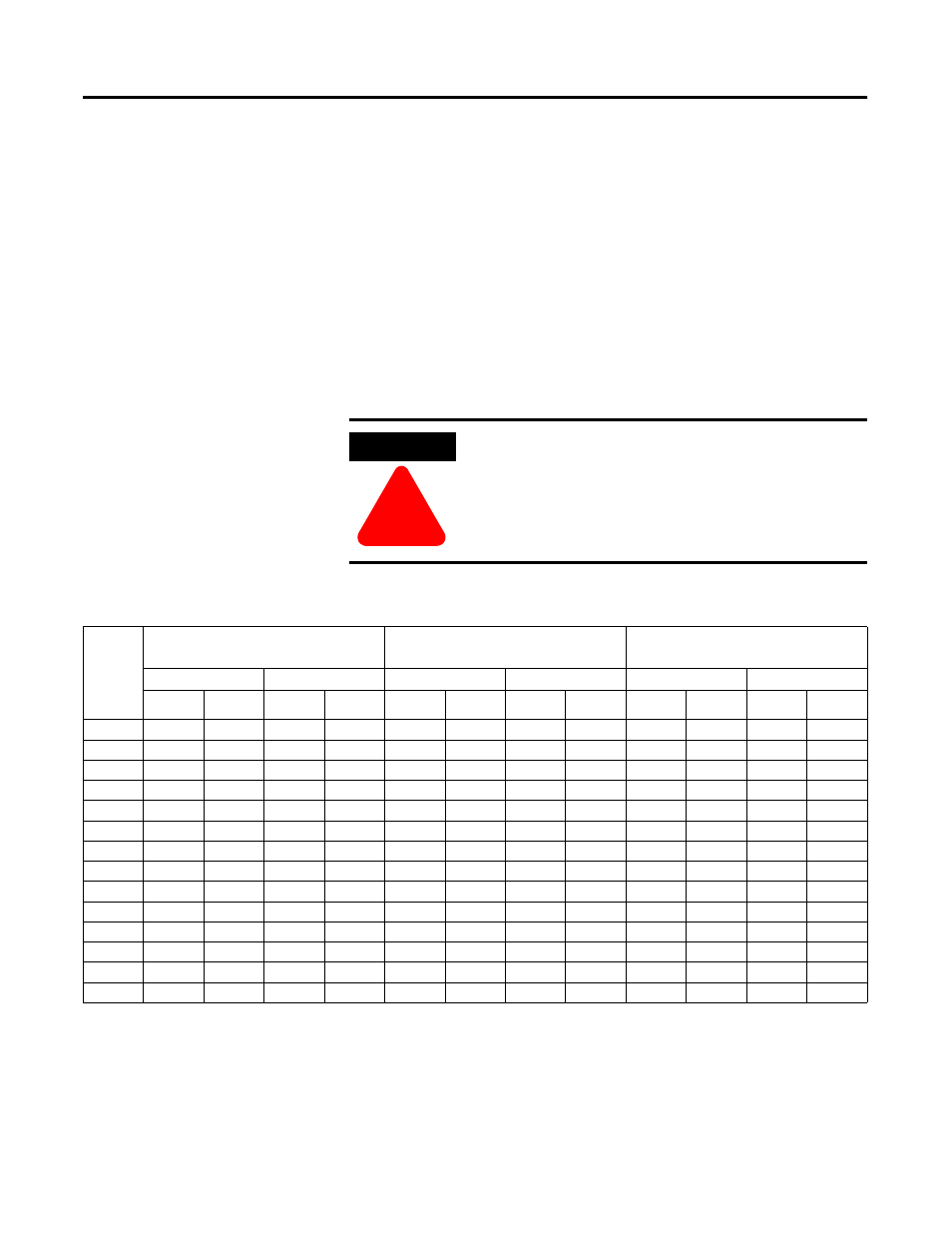

Table 2.N Recommended Seating Torques (Inch-Lb.) for Application in Various Materials

1960 Series Socket Head Cap Bolts (ANSI B18.3)

(1)

Bolt

Size

Mild Steel Rb 87

(2)

Cast Iron Rb 83

Brass Rb 72

(3)

Aluminum Rb 72

(4)

(2024-T

4

)

UNC

UNF

UNC

UNF

UNC

UNF

Plain

Cadmium

Plated

Plain

Cadmium

Plated

Plain

Cadmium

Plated

Plain

Cadmium

Plated

Plain

Cadmium

Plated

Plain

Cadmium

Plated

#0

-

-

2.1*

1.6*

-

-

2.1*

1.6*

-

-

2.1*

1.6*

#1

3.8*

4.7*

4.1*

3.0*

3.8*

2.9*

4.1*

3.0*

3.8*

2.9*

4.1*

3.0*

#2

6.3*

4.7*

6.8*

5.1*

6.3*

4.7*

6.8*

5.1*

6.3*

4.7*

6.8*

5.1*

#3

9.6*

7.2*

10.3*

7.7*

9.6*

7.2*

10.3*

7.7*

9.6*

7.2*

10.3*

7.7*

#4

13.5*

10*

14.8*

11*

13.5*

10*

14.8*

11*

13.5*

10*

14.8*

11*

#5

20*

15*

21*

16*

20*

15*

21*

16*

20*

15*

21*

16*

#6

25*

19*

28*

21*

25*

19*

28*

21*

25*

19*

28*

21*

#8

46*

34*

48*

36*

46*

34*

48*

36*

46*

34*

48*

36*

#10

67*

50*

76*

57*

67*

50*

76*

57*

67*

50*

76*

57*

1/4

158*

119*

180*

136*

136

102

136

102

113

85

113

85

5/16

326*

245*

360*

270*

228

171

228

171

190

143

190

143

3/8

580*

435*

635

476

476

357

476

357

397

298

397

298

7/16

930*

698*

1,040*

780*

680

510

680

510

570

425

570

425

1/2

1,0420*

1,530*

2,250

1,690

1,690

1,270

1,690

1,270

1,410

1,060

1,410

1,060

(1)

All bolts must meet the specified grade or better.

(2)

Torques based on 80,000 psi bearing stress under head of bolt.

(3)

Torques based on 60,000 psi bearing stress under head of bolt.

(4)

Torques based on 50,000 psi bearing stress under head of bolt.

* Denotes torques based on 100,00 psi tensile stress in bolt threads up to 1” diameter.

To convert inch-pounds to inch-ounces, multiply by 16.

To convert inch-pounds to foot-pounds, divide by 12.