Motor storage, Mounting, Motor air gap – Rockwell Automation LC-Series Linear Motor User Manual

Page 21: Figure 2.13 typical mounting side view, Motor mechanical installation procedure, Motor storage -15 mounting -15

Item Number 814036 - Rev C

Installation 2-15

Motor Storage

Motor storage area should be clean, dry, vibration free and have a relatively

constant temperature. The coil resistance measurement checks explained in

this manual should be done at time of storage. If a motor is stored on

equipment, it should be protected from the weather. All motor surfaces

subject to corrosion should be protected by applying a corrosion resistant

coating.

Mounting

Motor Air Gap

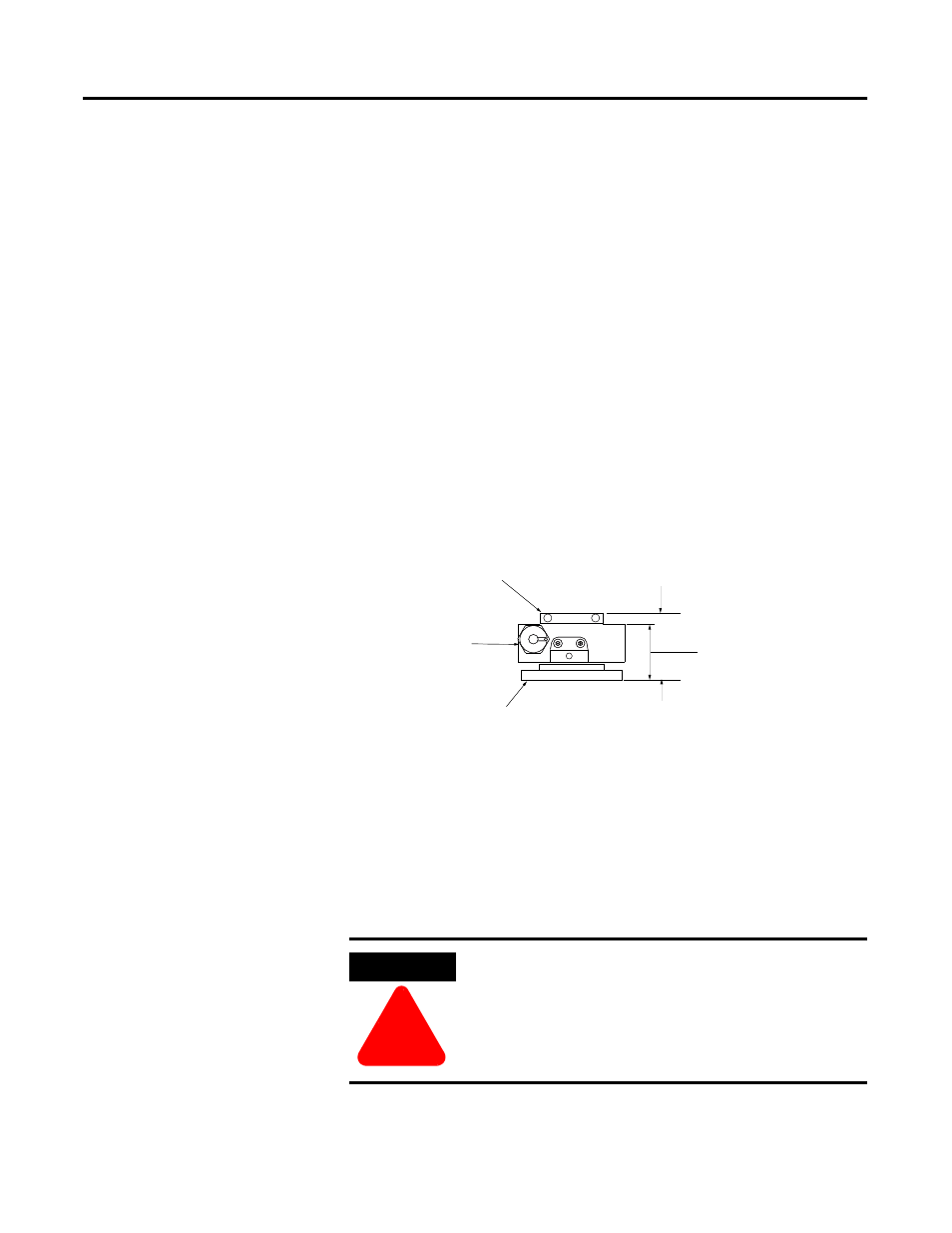

Maintaining the air gap is a critical aspect that affects the linear motor

installation and operation. Referring to Coil and Cooling Plate drawing for

your specific motor. By maintaining installation envelope dimension in your

design the required air gap will be met. Figure 2.13 Typical Mounting Side

View shows a typical mounting measurement.

Figure 2.13 Typical Mounting Side View

Motor Mechanical Installation Procedure

Linear motor components come with standard mounting holes. Use the

guidelines found in the following steps to maximize motor performance and

minimize the chance of motor damage.

ATTENTION

!

To avoid damage due to the magnetic attraction between

plates, maintain a minimum distance of five feet between

the magnet plates that are being installed and magnet plates

awaiting installation. Ensure that the supplied protective

devices (i.e. cardboard and metal plate) remain in place

until the installation processes is performed.

Magnet Track

Coil

Overall Dimensions

Optional Cooling

Plate Assembly

Overall Dimensions

with Cooling Plate

w/o Cooling Plate