Install cables – Rockwell Automation 2090-CPWM7DF-xxAFxx Continuous Flex Power Cables with DIN SpeedTec Connector Installation Instruc User Manual

Page 4

4 Continuous Flexible Power Cables Installation Instructions

Publication 2090-IN025A-EN-P — October 2009

Install Cables

Follow these steps when installing a cable.

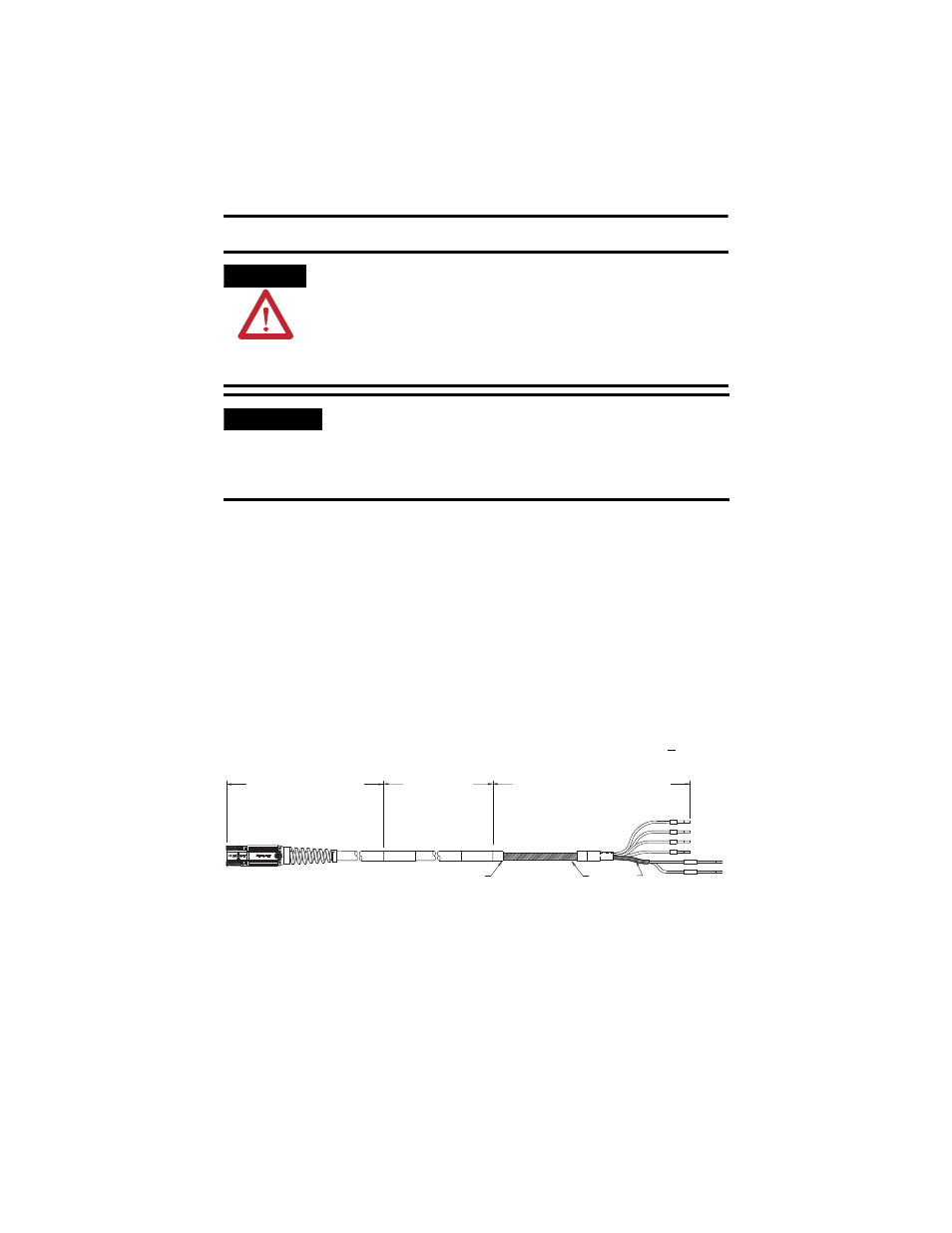

1. Identify the recommended installation areas and the correct offset from

features before beginning any cable bend. Features include these areas on

the cable:

• Connectors

• Transitions from exposed wire to insulation (for example, flying leads)

• Exposed cable ground shields

The offset from these features should be greater than or equal to (>1x) the

cable diameter.

2. Keep cable bends within the specified bend radius. Continuous flexible

cables have an operational bend radius of twelve times (12x) the cable

diameter.

ATTENTION

The examples in this publication show all the available connections, some of which

may not be appropriate for your specific installation. Refer to your drive installation or

user manual for recommended wire trim lengths, and wiring examples appropriate to

your drive and motor application.

Do not connect unused wires. Unused wires may be trimmed and finished as necessary

to prevent accidental contact with other wires or wire shields, or with a ground

connection.

IMPORTANT

Continuos flexible cables with SpeedTec connectors are incompatible with some

MP-Series motors.

Only install cables with a threaded connector on these motors: MPL-A15x0, MPL-A2x0,

MPL-B15x0, MPL-B2x0, MPS-A330, MPS-A4540, MPS-B330, MPS-B4540, and

MPS-B560.

U

Y

W

PE

WHITE

BLACK

MBRK+

MBRK-

Feature Offset

Minimum of 1x Cable Diameter

Flex Zone

2090-CPBM7DF-xxAFxx shown

Installation Area

300 mm (12 in.)

approx.

Installation Area

300 mm (12 in.)

approx.

Exposed

Shields