Rockwell Automation Arena Packaging Users Guide User Manual

Page 101

A

•

E

QUIPMENT

R

ELIABILITY

AND

L

OSS

95

•

•

•

• •

A •

R

eli

abi

lity

and Lo

ss

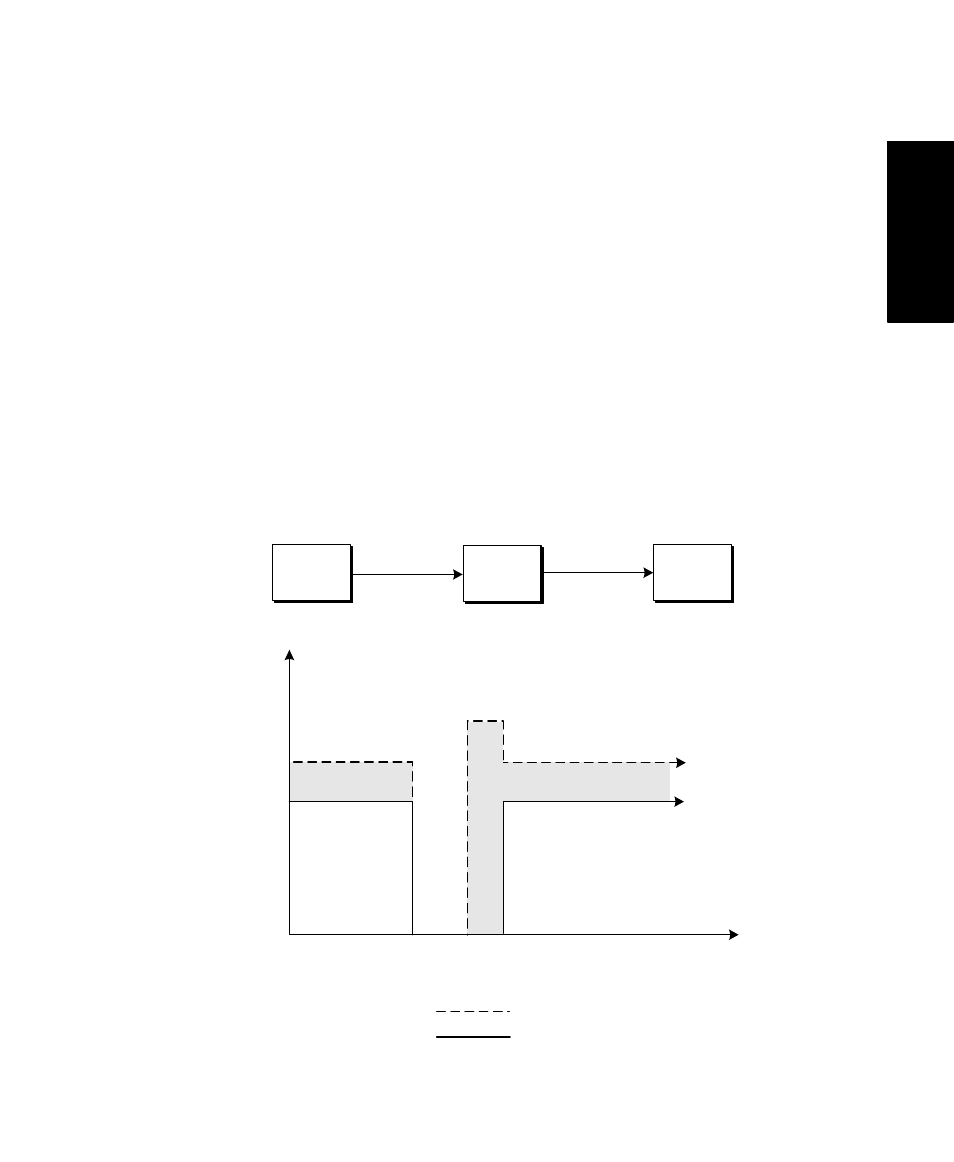

The first chart shows the output rate and good output rate of the machine over time if a

10% production loss is defined. Though the output rate of the machine is 100 units per

minute, the good output rate is only 90 units per minute because 10% of the product

produced by the machine is wastage. Of course, the machine produces nothing during the

failure from t

1

to t

2

.

The second chart shows the output rate and good output rate of the machine if, in addition

to a general 10% production loss, there are also units lost due to failures. At the end of the

failure at time t

2

, the machine immediately produces the quantity of Lost Units After

Failures. Then, the machine’s good output rate returns to 90 units per minute.

C

ONVEYOR

EXAMPLE

The chart below illustrates examples of both event- and production-based loss for an

accumulating conveyor. Suppose that the upstream basic machine is outputting good units

at a rate of 115 units per minute, the conveyor has a run speed (i.e., maximum transfer

rate) of 120 units per minute, and the downstream basic machine is running at 100 units

per minute. Suppose also that the conveyor has a 10% production loss, fails from time t

1

to

t

2

, and loses units when it fails.

Good Units

Lost Units

0

100

111

t

1

t

2

Good Units

Lost Units

Time

Rate

10% Production Loss & Lost Units After Failure

Total Output Rate of Conveyor

Good Output Rate of Conveyor

and Input Rate of Machine 2

Run Speed =

100 units/min

Basic

Machine 1

Basic

Machine 1

Conveyor

Conveyor

Basic

Machine 2

Basic

Machine 2

Run Speed = 120 units/min

Failure from t

1

to t

2

Good Output Rate =

115 units/min

120