Securing a motor control center, Securing a column or shipping block – Rockwell Automation 2500 CENTERLINE MCC Joining and Splicing Columns User Manual

Page 10

Publication 2500-IN004A-EN-P - August 2009

10 CENTERLINE 2500 Motor Control Centers Installing, Joining and Splicing Columns

Securing a Motor Control

Center

Documentation packages shipped with assembled MCCs include an

MCC elevation drawing showing an MCC floor plan layout. To secure

a column to the foundation refer to the provided floor plan layout and

the following procedures.

Refer to the CENTERLINE 2500 Installation Manual, publication

for cable and conduit routing instructions.

Securing a Column or Shipping Block

Each column is arranged to allow four steel M12 bolts (minimum

Property Class 8.8) to be used to securely fasten each MCC column

through its internal mounting angle to the foundation. Anchor bolts

(M12) may be pre-located and embedded in the foundation prior to

installation. Although four mounting holes are preferred, at least one

bolted connection is required in the front and rear of each MCC

column.

Follow these procedures for securing the MCC.

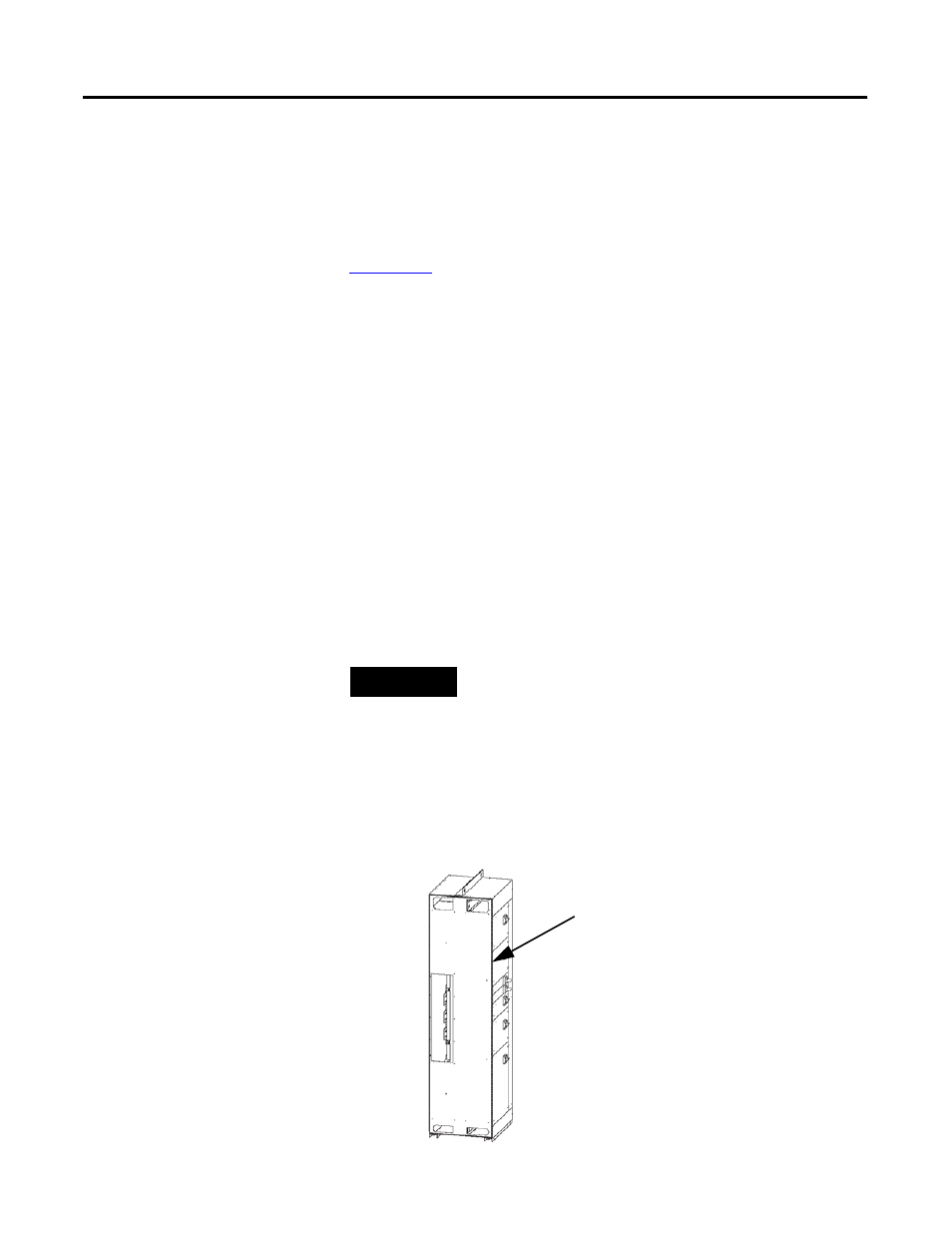

1. For IP 54 Enclosures, remove the tube of caulking (mastic)

sealer from the splice kit and read the application directions on

the tube.

2. Cut the nozzle at the first notch, 3 mm (0.125 in.) from the end.

3. Apply a continuous bead of caulking, 3 mm (0.125 in.) wide,

around the outside edge of the sideplate of the fixed motor

control center.

IP54 Sealing Caulk Location

TIP

For IP20, IP40, or IP42 Enclosures, no additional gasketing is required.

Apply 3 mm (0.125 in.) wide

continuous bead of caulking sealer.

Do not allow ‘skin’ to form on

caulking before joining the

sections.