Preliminary steps, Installing the overhead bus, Figure 2 overhead bus arrangement–example – Rockwell Automation 2364P Overhead Bus for Bulletin 2300 MCCs User Manual

Page 3

Publication 2364P-5.10 - December 1999

3

Preliminary Steps

Before you begin the procedures in this document:

1.

Verify that the individual shipping splits (MCC sections) are moved

into their final resting place and lined up sequentially according to the

section numbers located on the section data nameplate (see illustration

on the left). This sequence corresponds with the sequence defined on

your Certified Cabinet Outline Drawing.

2.

Verify that the shipping splits have been bolted together and that the DC

thru bus, control bus (if present), and TE/PE bus are spliced together

per publication 2300-5.1, Bulletin 2300 Family of Drive Systems

Hardware - Installation Manual.

3.

Remove all lifting angles per publication 2300-5.1, Bulletin 2300

Family of Drive Systems Hardware - Installation Manual.

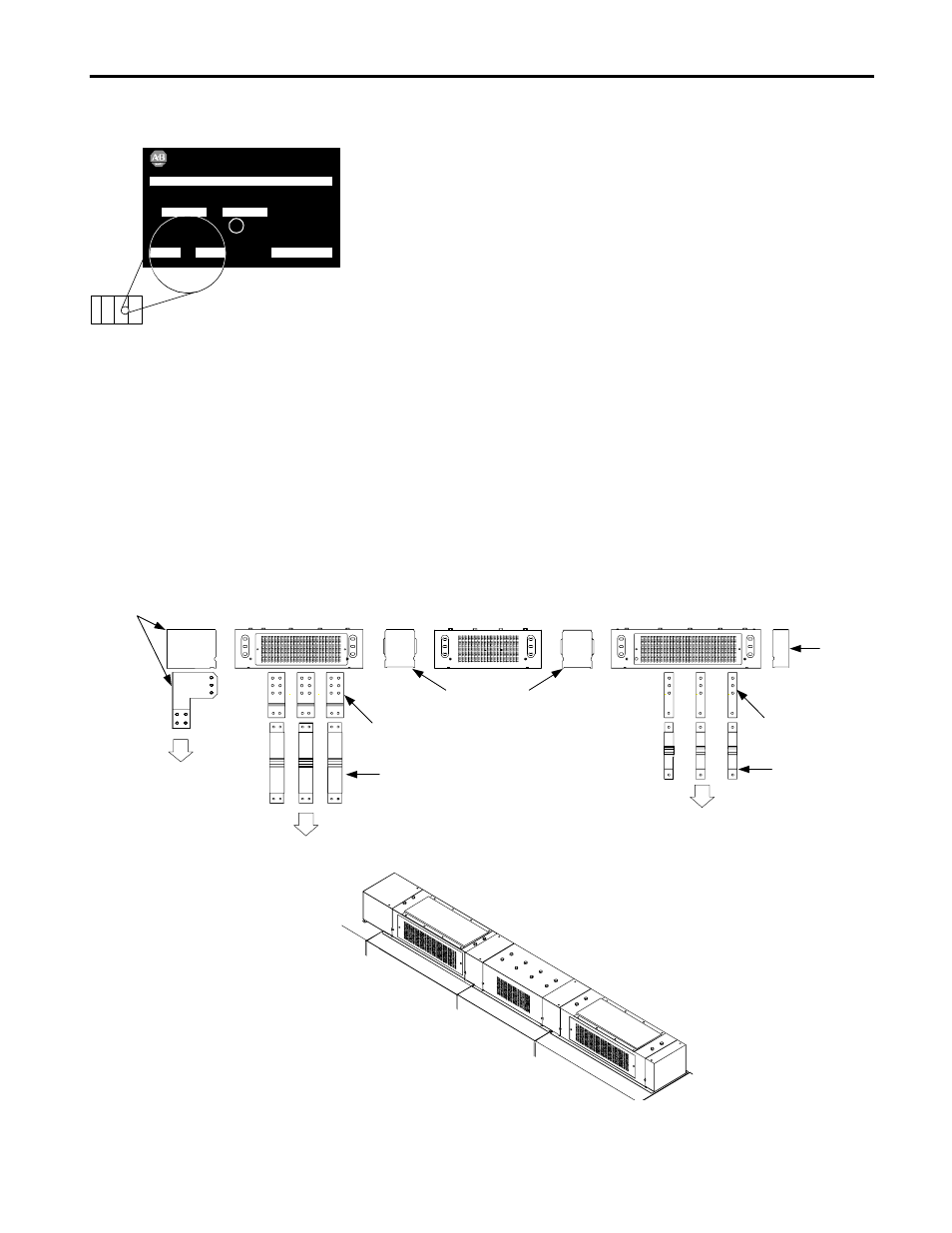

Installing the Overhead Bus

The figures in this publication (such as Figure 2) illustrate typical hardware

arrangements and assembly processes. Since there are several possible

overhead bus configurations, the figures are meant as a typical example. Be

sure to perform all of the installation instructions in accordance with the

Certified Cabinet Outline Drawing for your particular configuration.

Figure 2

Overhead Bus Arrangement–Example

2364PA-R3JB-14HAPC

3000

N/A

3

12

M-254, 201

MOTOR CONTROL CENTER SECTION

BUS RATING 810VDC MAX. (600 VAC RECT.)

BULLETIN 2100

MOTOR CONTROL CENTER

CATALOG NO./SERIAL NO.

EACH SIDE OF

HORIZONTAL BUS

SERIES

HORIZONTAL

VERTICAL

A

A

OF

PLANT 1C

MEQUON, WI U.S.A.

NO.

C

US

U

L

®

LIST ED

MCC

Identifying the MCC

Section Number

Feeder Splice

Assembly

Flex Bus

4" Bus Tabs

To circuit breaker

To Feeder Buswork

End Cap

Bus Assembly

Bus Assembly

To circuit breaker

Bus Assembly

Joiner-Splice

Assemblies

Flex Bus

2" Bus Tabs

3 Dimensional

View