Install cables – Rockwell Automation 2090-CPxxx Continuous-flex Power and Brake Extension Cable with DIN Connector User Manual

Page 4

4 Continuous-flex Power and Brake Extension Cable with SpeedTec Connector

Publication 2090-IN028B-EN-P - January 2011

Install Cables

Follow these steps when installing a cable.

1. Provide the recommended installation areas, and the correct offset from features, before

beginning any cable bend.

Features include these areas on the cable:

•

Connectors

•

Transitions from exposed wire to insulation (for example, flying leads)

•

Exposed cable ground shields

The offset from these areas should be greater than or equal to (>1x) the cable diameter.

2. Keep cable bends within the bend radius listed in the

.

General guidelines for the bend radius of a cable are listed below, however, individual

cables may have additional restrictions:

•

Non-flex cables have a static or one-time bend radius of 10 times (<10x) the cable

diameter.

•

Continuous-flex cables have an operational bend radius of 12 times (<12x) the cable

diameter.

3. Observe these restrictions on the flex zone and installation areas when installing the

cable:

•

The flex zone is the area in which the cable can flex many times without breakage.

•

Installation areas require rigid mounting to prevent the cable from flexing where it

connects to other components.

4. Identify each connection on a cable by attaching a label around the outer insulation of

each wire adjacent to the drive connection.

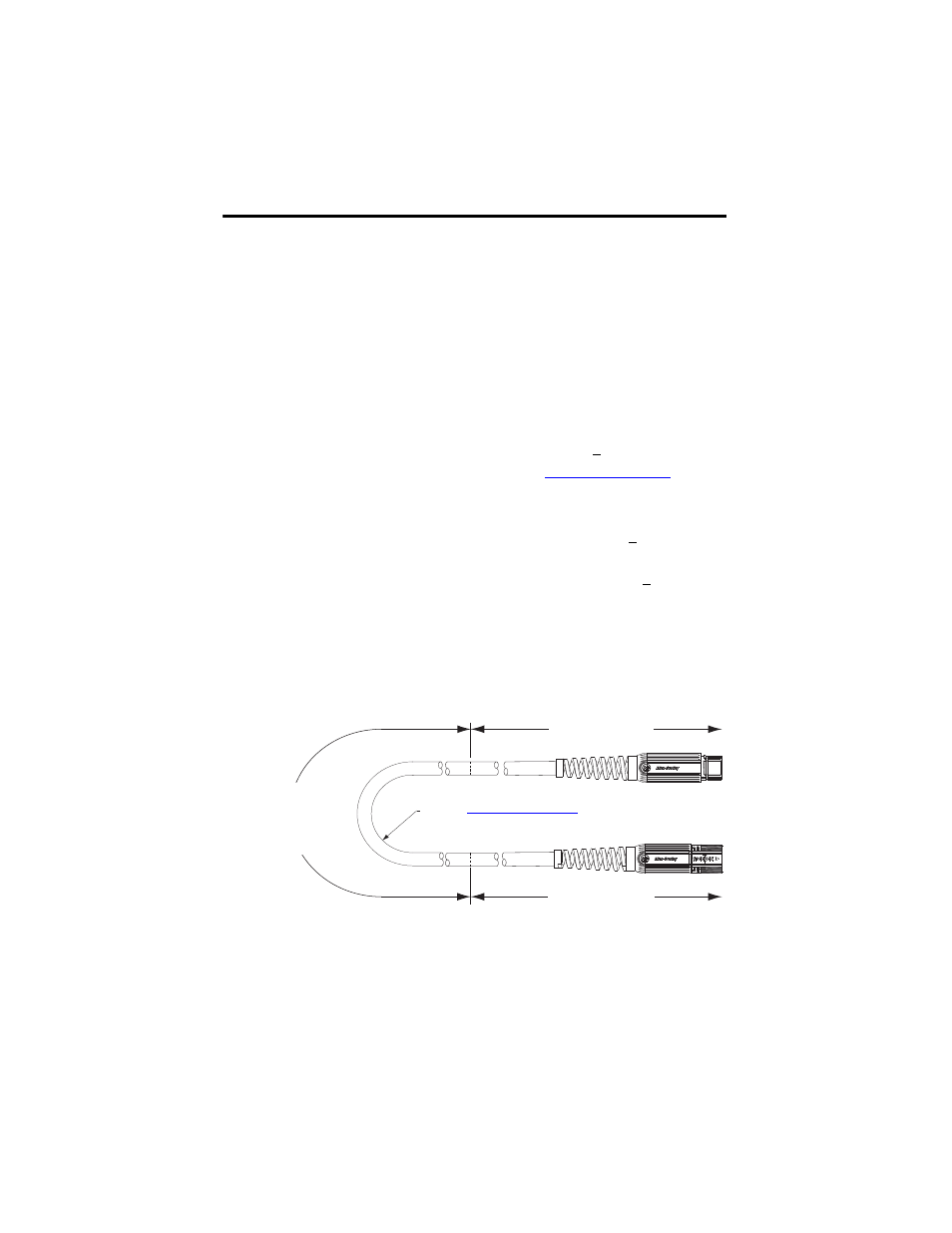

Flex Area

Dynamic and continuous

flexing permitted to the

operational bend radius.

2090-CPBM7E7-xxAFxx Shown

Installation Area

300 mm (12 in.) approx.

Bend Radius

Refer to

for the specific value.

Installation Area

300 mm (12 in.) approx.