Rockwell Automation 1502 400 Amp Medium Voltage Contactor (Series D) User Manual

Page 35

Maintenance

4-7

1502-UM050D-EN-P – June 2013

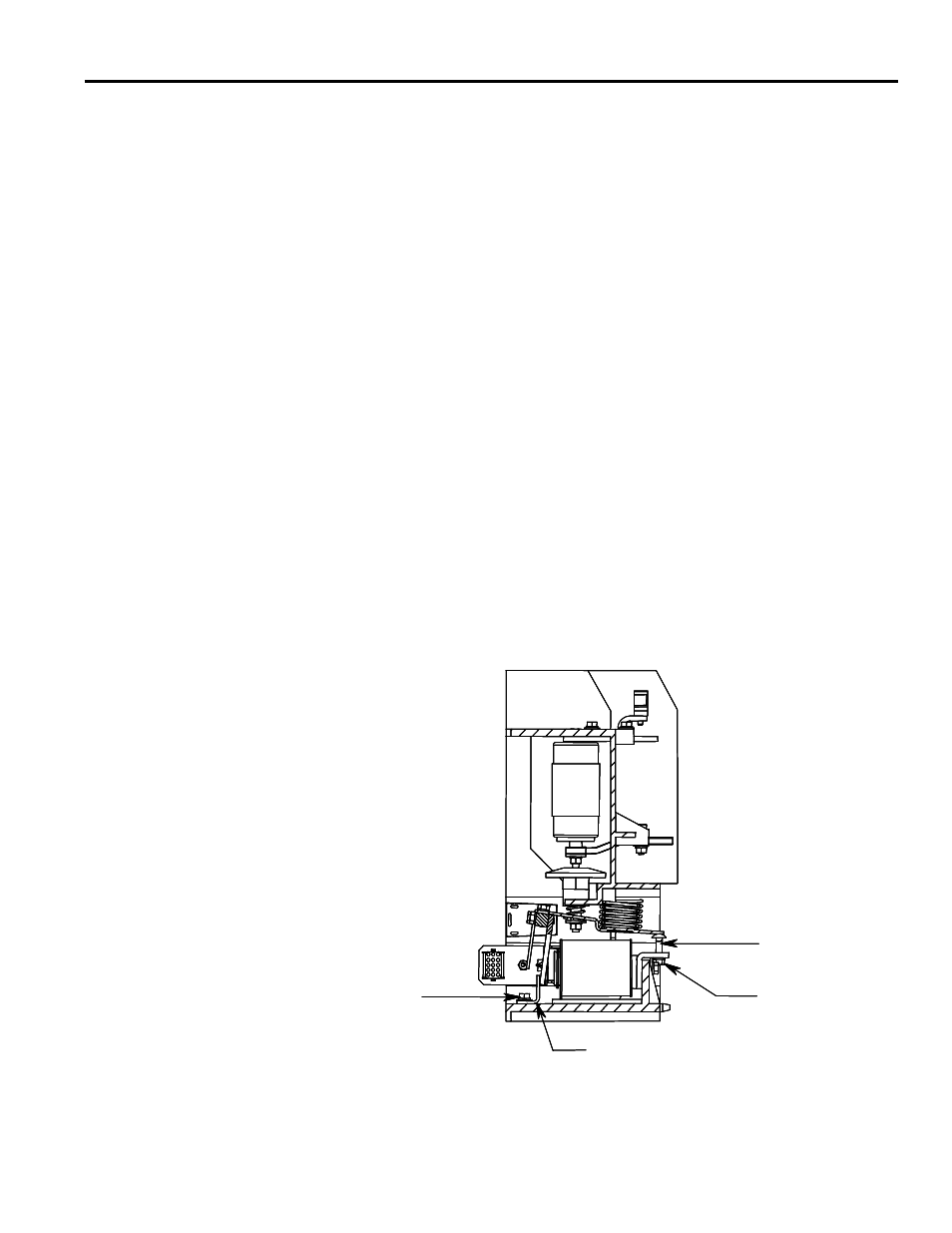

9. The contact gaps must be synchronized within 0.02 in. (0.5 mm). If the

gaps are not synchronized, rotate the insulators as required to achieve this.

Make sure the overtravel remains a minimum of 0.065 in. (1.65 mm) on

each bottle.

10. Tighten the load terminal nut on each bottle assembly. To do this without

damaging the bellows, apply wrenches to the load terminal nut and to the

flattened section of the movable bottle shaft. Tighten the load terminal nut

while holding the bottle shaft steady. Be careful not to turn the insulator

as this will change the gap.

11. The final contact gap for all three bottles must be between 0.180 in. and

0.200 in. (4.57 mm and 5.08 mm). If this is the case, the replacement

procedure is complete. If further adjustment is required, all three gaps can

be adjusted simultaneously by loosening the stop bracket bolts and

adjusting the height of the gap adjustment screw at the rear of the

contactor as shown in Figure 4.9. To adjust the height of the screw, first

loosen the locking nut.

12. When the gap is correct, tighten the gap adjustment screw locking nut.

Position the stop bracket lightly against the armature plate and tighten the

bolts securing the stop in position. Make sure that the actuator plate contacts

the gap adjustment screw and the armature plate contacts the stop bracket as

shown in Figure 4.9.

Stop Bracket Bolts

Gap Adjustment Screw

Gap Adjustment Screw

Locking Nut

Stop Bracket

Stop Bracket Bolts

Gap Adjustment Screw

Gap Adjustment Screw

Locking Nut

Stop Bracket

Figure 4.9 – Contact Gap Adjustment