Routine maintenance (cont.) – Rockwell Automation 1502 400 Amp Medium Voltage Contactor (Series D) User Manual

Page 30

4-2

Maintenance

1502-UM050D-EN-P – June 2013

Routine Maintenance (cont.)

To avoid shock hazards, lock out incoming power and

disconnect the control plug from the contactor before

working on the unit. Verify with a hot stick or meter that all

circuits are voltage free. Failure to do so may result in

severe burns, injury or death.

The following should be carried out on an annual basis or whenever a contactor

is serviced:

1. Cleaning

• Ensure that metal chips or filings are cleaned from around the

electromagnet assembly (coil core pole face and mating armature plate)

as they may affect proper operation of the contactor. Vacuum clean if

necessary.

Note: Do not use compressed air to clean or remove dirt from surfaces

or the enclosure as it will only redistribute the dirt.

• If dirty, clean the white ceramic area of vacuum bottles with a clean lint-

free cloth.

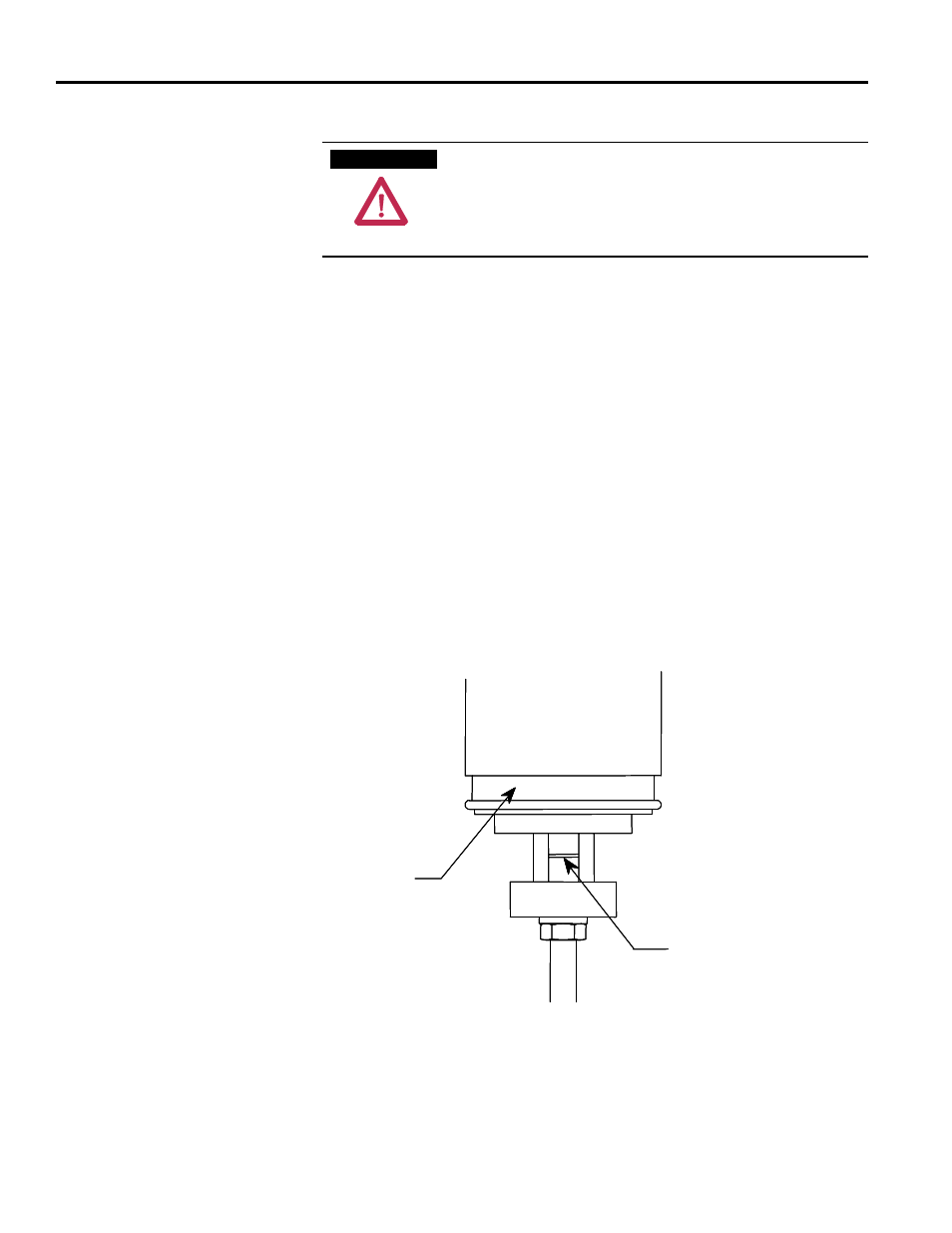

2. Main Contact Inspection

• Visually inspect the wear of the main contacts with the contactor

energized. When any part of the wear indicator line, located on the front

side of the hex shaft, moves up into the bearing, replace all three vacuum

bottles. (Refer to Figure 4.1).

Vacuum Bottle

Wear indicator line

On operating shaft

Vacuum Bottle

Wear indicator line

On operating shaft

Figure 4.1 – Vacuum Bottle Wear Indicator

A T T E N T I O N

A T T E N T I O N