Ds300 installation – Rockwell Automation 1397 200-300HP AC Line Disconnect Inst. User Manual

Page 5

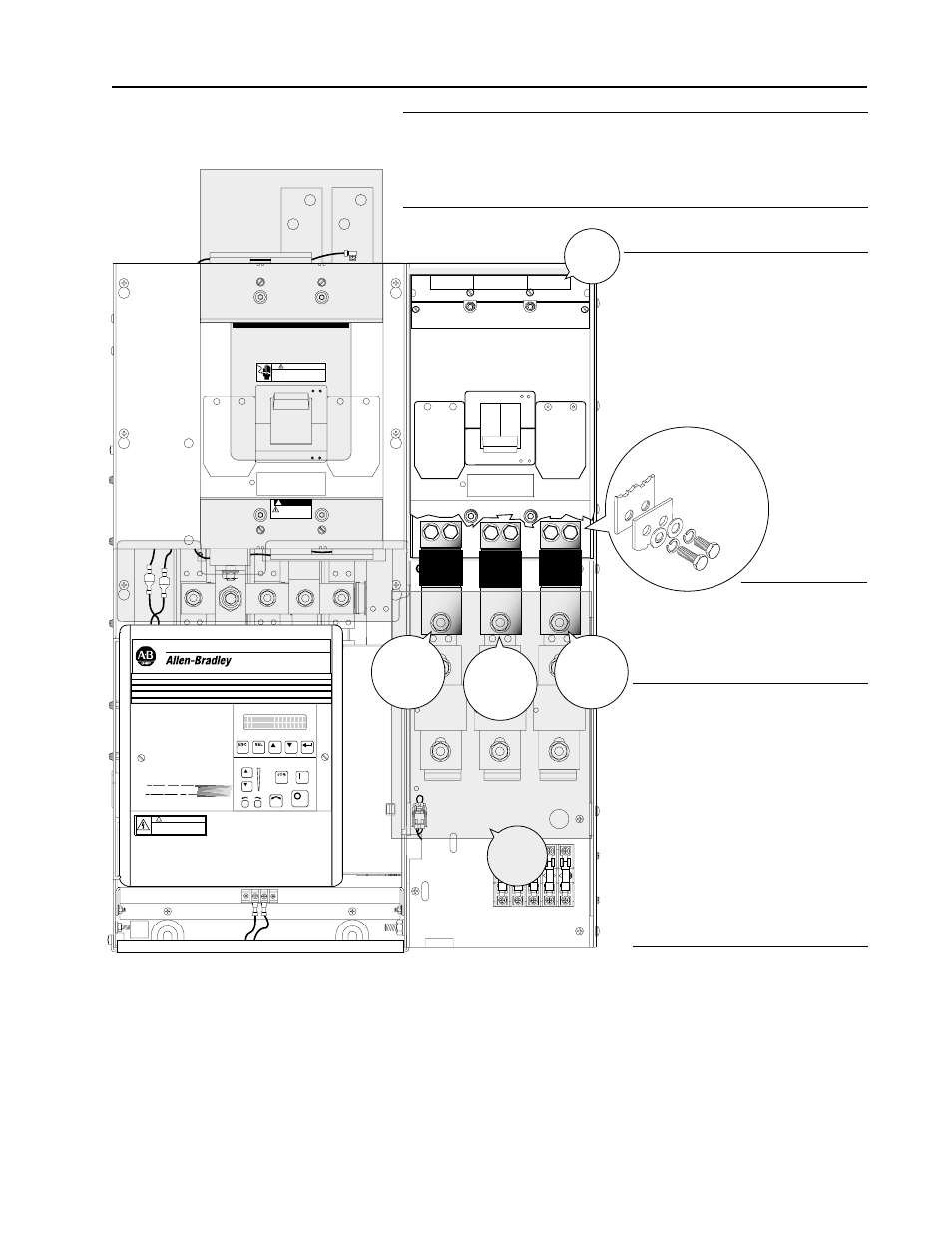

1397 300HP AC Line Disconnect

5

1397-5.27 October, 1997

TORQUE

14-10GA 35 LB.-IN.

0 GA 48 LB.-IN.

SPEC

GND

!

DANGER

RISK OF ELECTRICAL SHOCK. DISCONNECT INPUT

POWER BEFORE SERVICING EQUIPMENT.

P/N 33145

DANGER

CIRCUIT BREAKER DOES NOT DISCONNECT INCOMING A0

LINE POWER IT ONLY PROVIDES DC FAULT PROTECTION.

LE DISCONECTEUR NE COUPTE PAS L'AUTOMENTATION DU SPOTEUR IL NES

SERT QUE A ASSURER UNE PROTECTION CONTRE LES DESFAULTS DC.

810903-2424

283

282

281

4FU 5FU 6FU 7FU 8FU

183

182

181

RISK OF SHOCK

REPLACE AFTER

SERVICING

DANGER

!

Plastic

Line Fuse

Cover

81

82

83

ON

OFF

Line Side

Label

M12 Nut

and Washer

Removed

Previously

M12 Nut

and Washer

Removed

Previously

M12 Nut

and Washer

Removed

Previously

7/16"

Flat Washer

7/16" Split

Lockwasher

7/16" x 1" Bolt

— (6) Places —

❐

7a

Remove the disconnect’s bottom lug cover by loosening the (2)

screws holding it in place. Put one split lockwasher and one flat

washer onto each of the bolts used to fasten the bus bars to the

disconnect.

DS300 Installation

❐

7b

Attach one bus bar to the

drive’s left line fuse connector

and the disconnect’s left load

connector. One of the holes on

the bus bar attaches to the lug

for the line fuse connector. Use

(2) of the bolt, lockwasher and

flat washer 7/16" assemblies

❐

7c

Fasten the bus bars to the

drive’s line fuse connectors

with the M12 nuts and

washers removed in

Step 1

.

• Tighten the bolts fastening

the bus bars to the

disconnect to 40N-m

(350lb.-in.).

• Tighten the nuts fastening

the bus bars to the line fuse

connectors to 40N-m

(350lb.-in.).

to attach the bus

bar to the

disconnect.

Repeat this

procedure to

attach the

remaining

bus bars.