Disassembly and reassembly instructions, Air gap and shimming, Axial float – Rockwell Automation 1325L DC Motors, Frames C210ATZ - C440ATZ User Manual

Page 23: Anti-friction bearing assemblies, Bearing replacement

DC Motors

23

Disassembly and Reassembly

Instructions

The motor design incorporates many new techniques which are

described in this section. It is recommended that these differences be

understood thoroughly before any disassembly work is done to avoid

possible damage or harm to either machine and/or maintenance

personnel.

Air Gap And Shimming

(Frames C210ATZ - C400ATZ)

Main Pole

Steel or brass shims, when used, are placed between pole and frame.

If for any reason the shims are removed they must be replaced under

the same poles. Main pole bolts are steel SAE Grade 5 (120,000 psi).

Interpoles

Excluding the C440ATZ frame, interpoles are an integral part of the

frame and do not require nor are they capable of shimming.

Axial Float

Motors have a wave spring washer between the drive end bracket and

bearing. The commutator end bearing is positioned axially by a float

restricting inner cap. Axial float (including bearing internal

clearance) should be within the limits listed below.

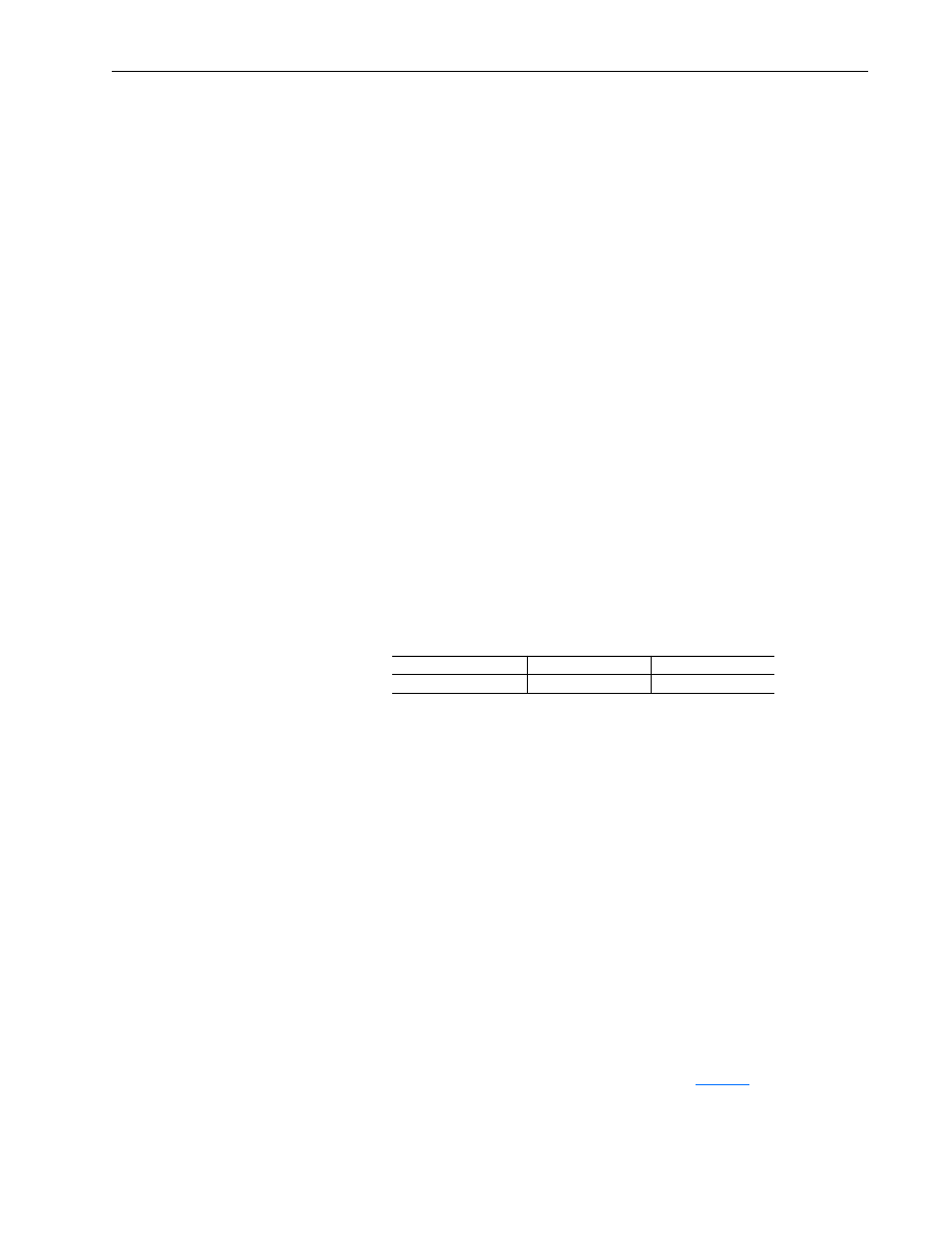

Axial Float

Anti-Friction Bearing Assemblies

The bearings are positioned and secured in a machined cavity in the

end brackets. Open type ball bearings are used for direct coupled and

belt drive applications for frames C210ATZ - C250ATZ and are

protected by inner caps at both ends.

Frames UC360ATZ - C440ATZ employ a cylindrical roller bearing

on the drive end for belt drives, and a ball bearing for coupled service.

Bearing Replacement

Remove bearing by means of bearing puller. Clean bearing housing

and bearing seat prior to assembly of bearing. Place new bearing in a

bake oven for 1/2 hour at 121 degrees C (250 degrees F). Place

bearing onto shaft and push home to bearing shoulder. Hold it in

place for a minimum of 30 seconds.

After bearing has cooled down for about 1 minute, add 1/2 cu. in. of

fresh grease into back of bearing. When the motor has been

assembled, grease per instructions found on

Frame

Maximum

Minimum

C210ATZ - C440ATZ

1.29 mm (0.051 in.)

0.33 mm (0.013 in.)