Reliability, Terminals and wiring – Rockwell Automation 1606-XLERED Power Supply Reference Manual User Manual

Page 6

All parameters are specified at 24V, 2.5A, 230Vac input, 25ªC ambient and after a 5 minutes run-in time unless noted otherwise.

6

Rockwell Automation Publication 1606-RM033A-EN-P — March 2014

Bulletin 1606 Switched Mode Power Supplies

6. Reliability

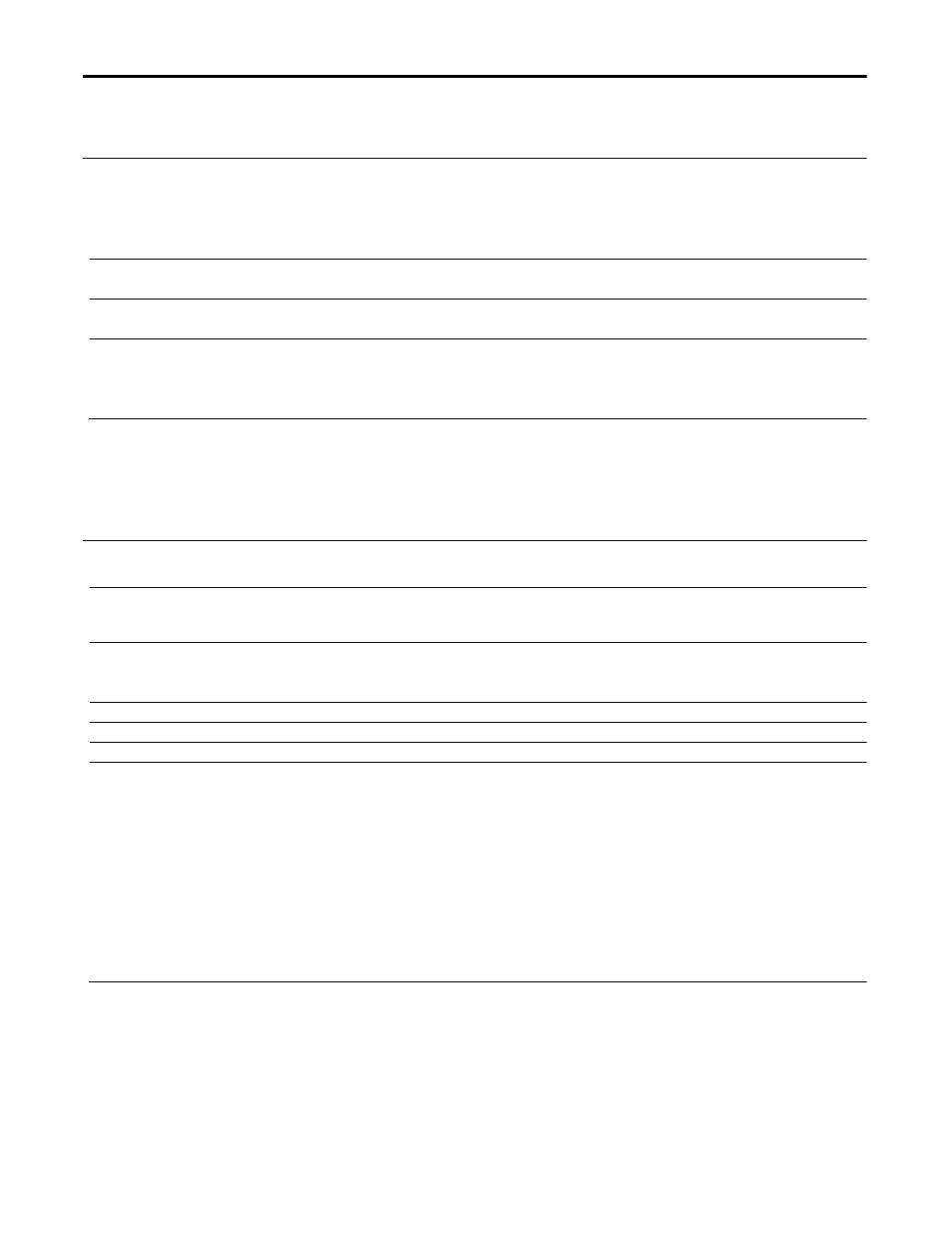

The redundancy module does not include electrolytic capacitors. Therefore, the lifetime expectancy and MTBF

value are extremely high.

Input / output

current conditions

Input: 2x10A

Output: 20A

Input: 2x5A

Output: 10A

Lifetime expectancy

*)

min.

25 years

25 years

at 24V and 40°C

min.

25 years

25 years

at 24V and 25°C

MTBF

**)

SN 29500, IEC 61709

9 100 000h

10 900 000h

at 24V 40°C

15 700 000h

18 800 000h

at 24V 25°C

MTBF

**)

MIL HDBK 217F

9 200 000h

11 100 000h

at 24Vand 40°C (Ground Benign GB40)

12 600 000h

15 100 000h

at 24Vand 25°C (Ground Benign GB25)

3 380 000h

4 060 000h

at 24Vand 40°C (Ground Fixed GF40)

4 630 000h

5 570 000h

at 24Vand 25°C (Ground Fixed GF25)

*) The

Lifetime expectancy shown in the table indicates the minimum operating hours (service life).

**)

MTBF stands for Mean Time Between Failure, which is calculated according to statistical device failures, and indicates reliability of a

device. It is the statistical representation of the likelihood of a unit to fail and does not necessarily represent the life of a product.

7. Terminals and Wiring

Input and output terminals

Alarm-signal terminals

Type Screw

terminals

IP20 Finger safe construction.

Suitable for field installation.

Screw terminals, pluggable

IP20 Finger safe construction.

Suitable for field installation.

Solid wire

0.5-6mm

2

0.2-1.5mm

2

Stranded wire

0.5-4mm

2

0.2-1.5mm

2

American Wire Gauge

20-10 AWG

22-14 AWG

Wire stripping length

7mm / 0.28inch

6mm / 0.25inch

Screwdriver

3.5mm slotted or Pozidrive No 2

3mm slotted

Recommended tightening torque

0.8Nm / 7lb.in

0.4Nm / 3.5lb.in

Instructions:

a) The external circuitry of all terminals (including signalling contacts) must meet the safety requirements stipulated by

IEC/EN/UL 60950-1: SELV.

b) Use appropriate copper cables that are designed for minimum operating temperatures of:

60°C for ambient up to 45°C and

75°C for ambient up to 60°C minimum.

c) Follow national installation codes and installation regulations!

d) Ensure that all strands of a stranded wire enter the terminal connection!

e) Up to two stranded wires with the same cross section are permitted in one connection point.

f) Screws of unused terminal compartments should be securely tightened.

g) Ferrules are allowed, but not required.

h) Do not connect or disconnect the wires from the terminals below -25°C (-13°F).