Rockwell Automation 1494V-DS400_DS600 Disconnect Switch (400/600A - Series A) User Manual

Page 6

1025456

2

DISCONNECT SWITCH AND ACCESSORY KITS

INSTALLATION INSTRUCTION SHEET

1

42052-073

OF

N/A

N/A

N/A

REVISION

AUTHORIZATION

DR.

CHKD.

APPD.

DATE

DATE

DATE

E - DOC

LOCATION: MILWAUKEE, WISCONSIN U.S.A.

B-vertical.ai

DWG.

SIZE

SHEET

B

1

2

3

4

5

6

7

8

A

B

C

D

E

F

G

H

REFERENCE

DIMENSIONS APPLY BEFORE

SURFACE TREATMENT

(DIMENSIONS IN INCHES)

TOLERANCES UNLESS

OTHERWISE SPECIFIED

.XX:

.XXX:

ANGLES:

42052

---------------

---------------

---------------

---------------

---------------

---------------

6

8

1006259

1

2

3

Connecting

Rod

Min.

Max.

"N"

Standard

Extended

Catalog Number

1494V-RB1

1494V-RB2

9"

9-1/4"

9"

23"

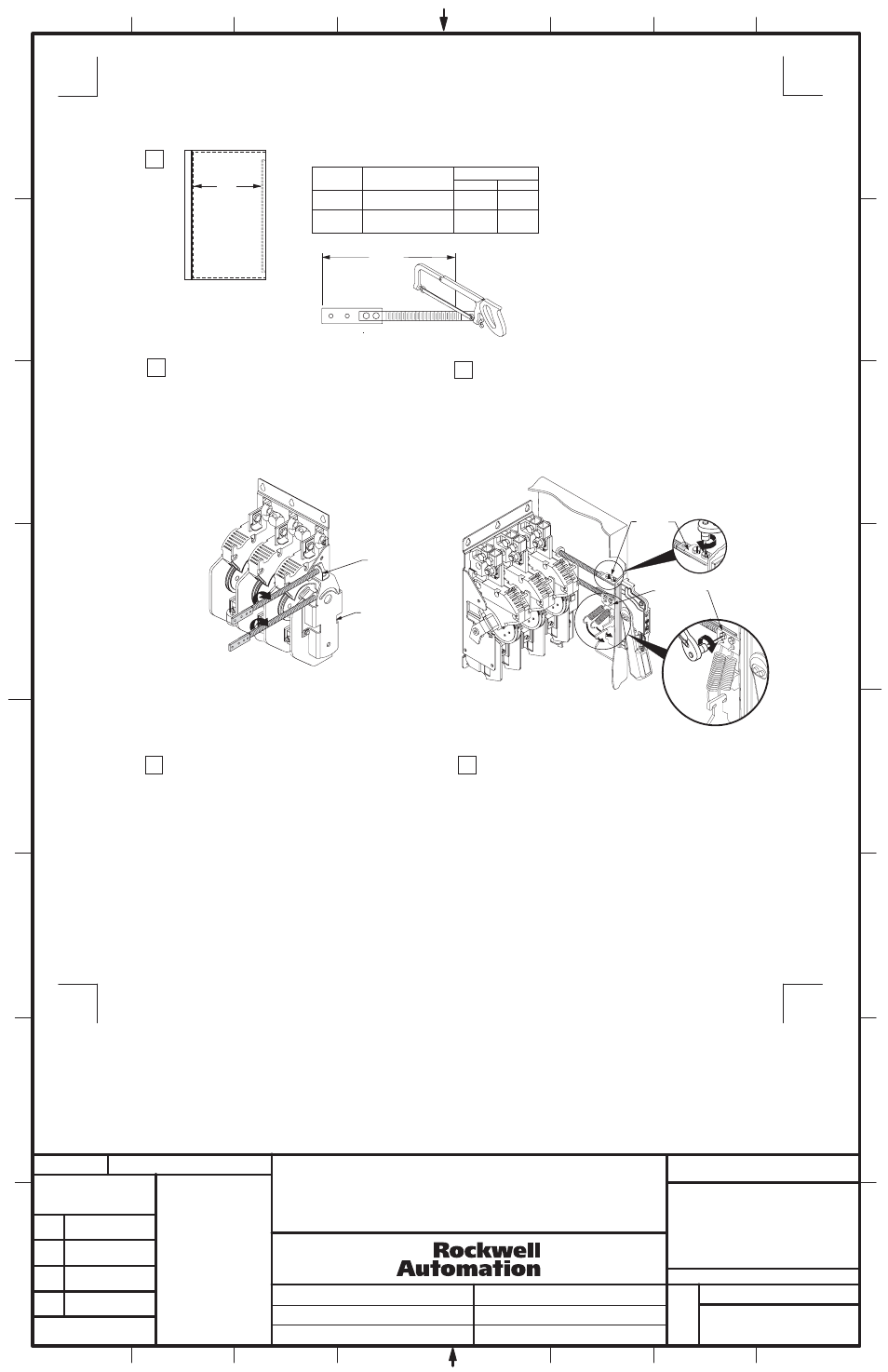

Connecting Rod Installation

Right Hand Operation

Connecting Rod Adjustment Procedure

N

Enclosure

Working Depth

(Flange to

Mounting Plate)

N - 3"

Front

Connecting

Link

a) Install connecting rod into the support rod bracket and

thread in clockwise (5) full turns

b) Install connecting rod into the drive bar mechanism

and thread in clockwise (9) full turns

a) Place the disconnect handle in the "OFF" position. Attach

the end of the connecting rod to the primary link of the handle

with two 1/4-20 x 1/2" slotted head screw assemblies and

tighten to 40 lb-in torque.

b) Attach the second connecting rod to the top of the spring

bracket with two 1/4-20 x 1/2" slotted head screw assemblies

and tighten to 40 lb-in torque.

c) Attach the two springs to the mechanism as shown below:

4

5

"ON" Position

a) Move disconnect handle to the "ON" position.

b) If switch does not fully close, return handle to "OFF"

position.

c) Loosen and remove the two 1/4-20 slotted hex head screw

assemblies that hold the connecting rod to the connecting link.

d) Turn connecting rod counter-clockwise (1) full turn.

e) Re-assemble the two 1/4-20 hex head assemblies and

tighten to 40 lb-in and re-test.

f) Repeat 4a - 4e as necessary.

"OFF" Position

g) Move disconnect handle to the "OFF" position.

h) If switch does not fully open, return handle to "ON" position.

j) Loosen and remove the two 1/4-20 slotted hex head screw

assemblies that hold the connecting rod to the connecting link.

k) Turn connecting rod clockwise (1) full turn.

l) Re-assemble the two 1/4-20 hex head assemblies and tighten

to 40 lb-in and re-test.

m) Repeat 5g - 5l as necessary.

(6)

Spring

Bracket

Support Rod

Bracket

Drive Mechanism

THIS DRAWING IS THE PROPERTY OF

ROCKWELL AUTOMATION, INC.

OR ITS SUBSIDIARIES AND MAY NOT BE COPIED,

USED OR DISCLOSED FOR ANY PURPOSE

EXCEPT AS AUTHORIZED IN WRITING BY

ROCKWELL AUTOMATION, INC.