E - doc, Disconnect switch installation 1 – Rockwell Automation 1494V-DS400_DS600 Disconnect Switch (400/600A - Series A) User Manual

Page 3

1025456

2

3

8

DISCONNECT SWITCH AND ACCESSORY KITS

INSTALLATION INSTRUCTION SHEET

1

1006259

42052-073

OF

N/A

N/A

N/A

REVISION

AUTHORIZATION

DR.

CHKD.

APPD.

DATE

DATE

DATE

E - DOC

LOCATION: MILWAUKEE, WISCONSIN U.S.A.

B-vertical.ai

DWG.

SIZE

SHEET

B

1

2

3

4

5

6

7

8

A

B

C

D

E

F

G

H

REFERENCE

DIMENSIONS APPLY BEFORE

SURFACE TREATMENT

(DIMENSIONS IN INCHES)

TOLERANCES UNLESS

OTHERWISE SPECIFIED

.XX:

.XXX:

ANGLES:

42052

---------------

---------------

---------------

---------------

---------------

---------------

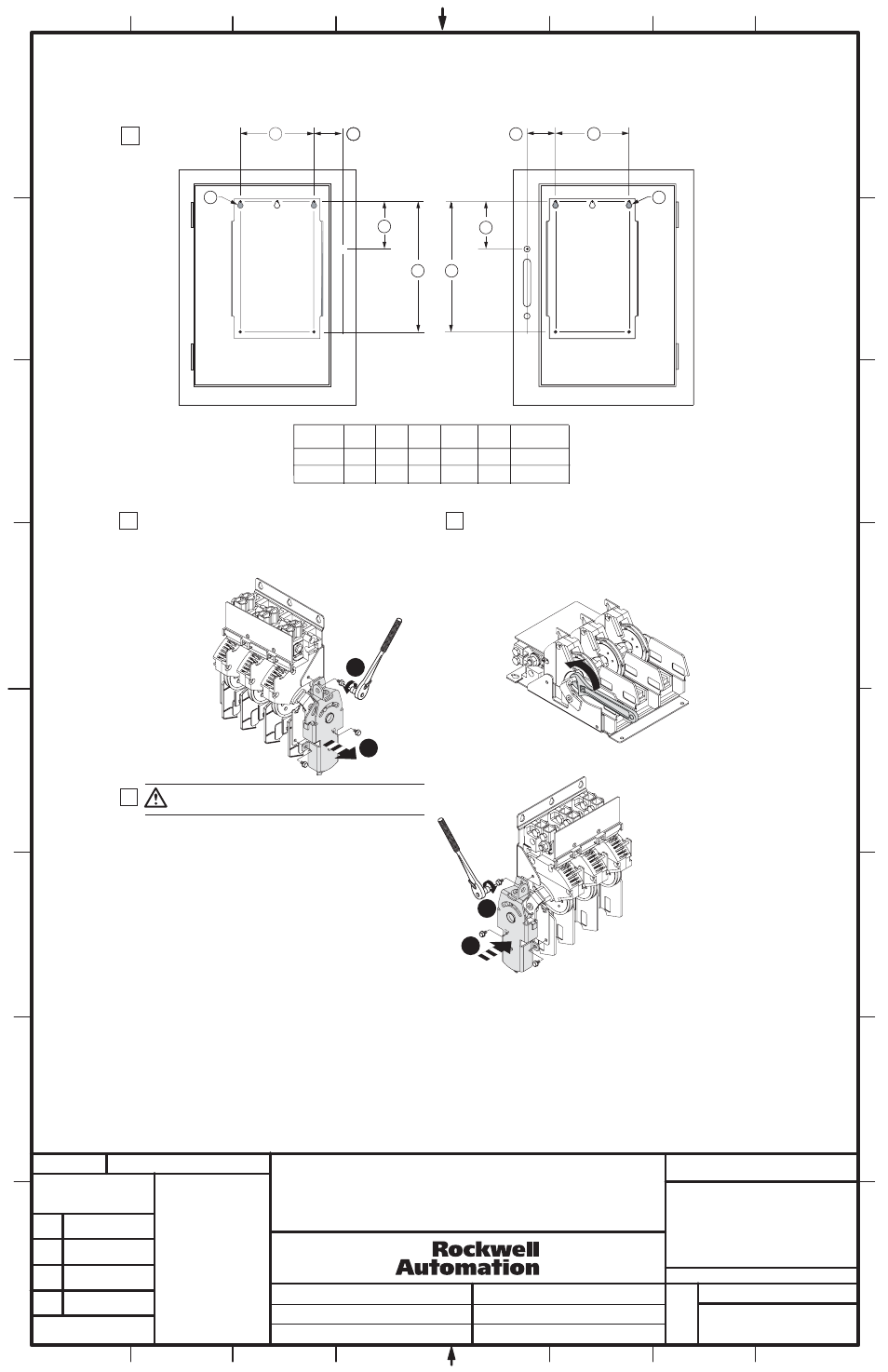

Disconnect Switch Installation

1

2 - 5/64"

6 - 5/32" 8 - 17/64" 14 - 31/32"

(4) 5/16-18

2 - 5/64"

AA

BB

CC

DD

NEMA

SIZE

400A

2 - 5/64"

6 - 5/32" 8 - 17/64" 14 - 31/32"

(4) 5/16-18

2 - 5/64"

600A

GG

HH

BB

BB

DD

CC

AA

AA

AA

AA

AA

AA

Locate

Disconnect

Switch

Right Hand Flange

Left Hand Flange

HH

DD

GG

CC

HH

Rotate the crossbar assembly to the "ON" position (blades fully

engaged - not visible).

(Use any convenient adjustable wrench to aid in rotating the

crossbar & moveable blades.

ATTENTION: Do not attempt to change the position of the

drive mechanism after removal from the disconnect assembly.

With the disconnect switch in the "OFF" position, (blades visible)

loosen and remove the (3) hex head screws.

Remove the drive mechanism from the right-hand side of the

disconnect switch.

Save the (3) 5/16-18 hex head screws shown below.

Conversion from Right-Hand Installation to Left-Hand Installation

2

3

4

40-60 lb-in

(3)

Position the drive mechanism assembly as shown below and install

the (3) 5/16-18 hex head screws.

L1

L2

L3

L1

L2

L3

L1

L2

L3

THIS DRAWING IS THE PROPERTY OF

ROCKWELL AUTOMATION, INC.

OR ITS SUBSIDIARIES AND MAY NOT BE COPIED,

USED OR DISCLOSED FOR ANY PURPOSE

EXCEPT AS AUTHORIZED IN WRITING BY

ROCKWELL AUTOMATION, INC.

2

1

1

2