Quick installation guide, Cutting connecting rod, Top handle h ole bo tt om handle h ole – Rockwell Automation 1494V-DSxx Series D Variable Depth Disconnect Switch User Manual

Page 2: Top bo tt

A

HOLD FLUSH

TO

INSIDE

OF ENCLOSURE

MEASURE T

O

INSIDE OF

THE

TOP OF ENCLOSURE

TOP HANDLE H

OLE

BO

TT

OM HANDLE H

OLE

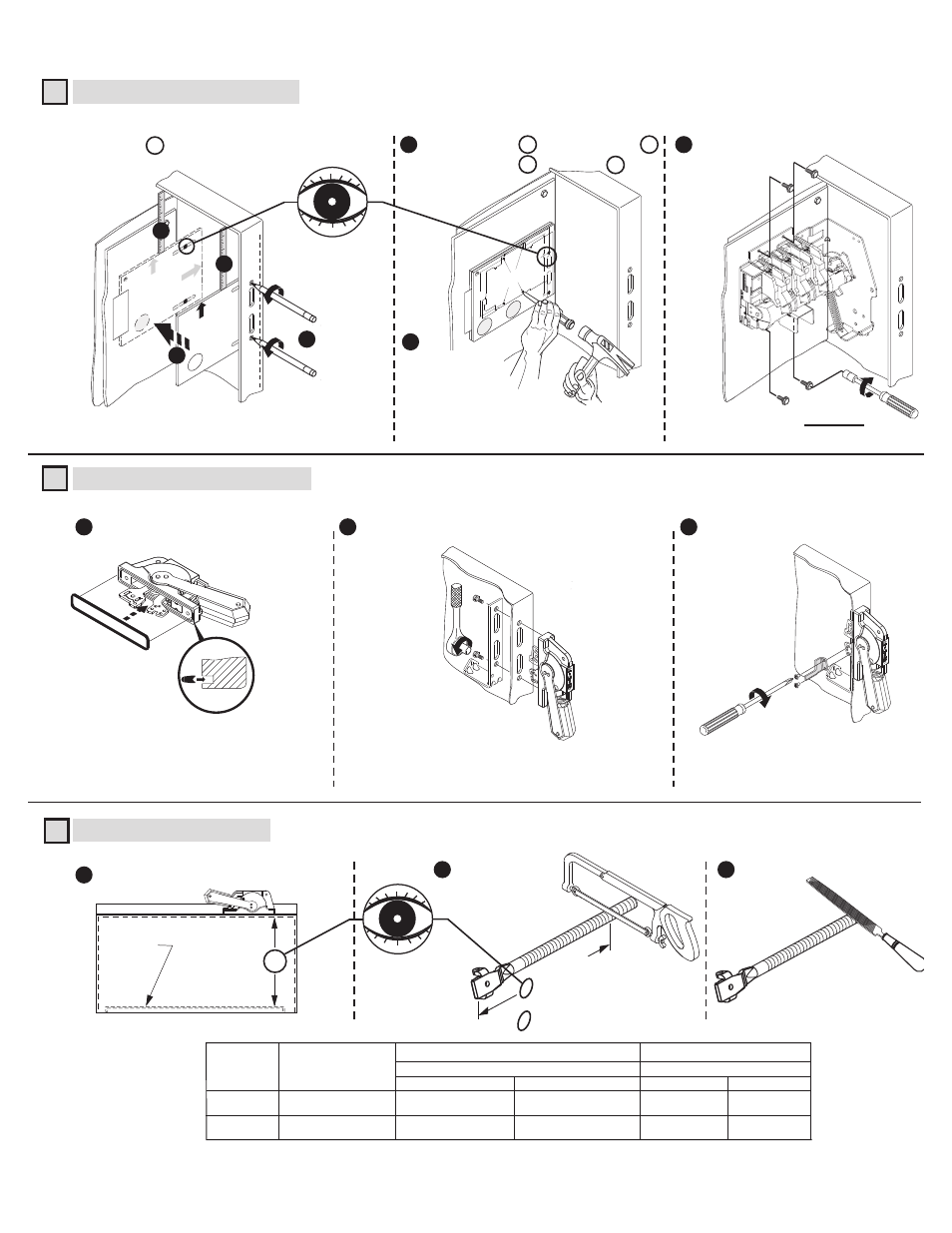

Disconnect Handle Installation

Disconnect Switch Installation (Right hand installation shown. For left hand installation follow similar procedure.)

1

2

Install gasket.

30-40 lb-in

Install handle and spring bracket.

Use template A to locate handle holes on mounting plate.

Overlay template B (30 A - 100 A) over A .

Overlay template C (200 A) over A .

7-11 lb-in

Install defeater lever.

Cutting Connecting Rod

N

Enclosure

Working Depth

(Inside Flange

of Enclosure to

Mounting Plate)

Mounting

Plate

Measure working depth of enclosure.

3

Measure, mark and

cut connecting rod.

N minus 3-1/8"

(30A - 100A)

N minus 3-1/4"

(200A)

23 - 37 lb-in

(30A - 100A)

40 - 60 lb-in

(200A)

TAPE

HOLD FLUSH

TO

INSIDE

OF ENCLOSURE

MEASURE T

O

INSIDE OF

THE

TOP OF ENCL

OSURE

TOP

BO

TT

2

4

A

1

1

5

1

1

2

Remove burrs

3

2

3

Install disconnect switch.

7

6

1

3

A

HOLD FLUSH

TO

INSIDE

OF ENCLOSURE

MEASURE T

O

INSIDE OF

THE

TOP OF E

NCLOSURE

TOP

BO

TT

B

or

C

2 - 1/4"

5 - 1/4"

2 - 1/4"

4 - 11/16"

3 - 1/16"

Switc

h Mounting Holes

Center punc

h and drill (4) 11/64" holes f

or

tap-tite scre

ws pr

ovided with

switc

h

Center punch and

drill (4) holes

for thread forming

(TAP-TITE) screws

provided with switch.

11/64" Dia. (30A - 100A)

7/32" Dia (200A)

PN-47400

DIR 10000056505 (Version 00)

QUICK INSTALLATION GUIDE

(2)

6 - 3/4"

30A - 60A - 100A Disconnect Switches

“N”

Min.

6 - 3/4"

9 - 1/8"

Max.

21 - 5/8"

8 - 1/2"

200A Disconnect Switches

“N”

Min.

8 - 1/2"

10 - 1/4"

Max.

22 - 3/4"

1494V-RA3

1494V-RA4

Catalog

Number

Connecting

Rod

Standard

Extended