Rockwell Automation 442L SafeShield Safety Light Curtain Hardware User Manual

Page 9

SafeShield Safety Light Curtain Hardware User Manual

9

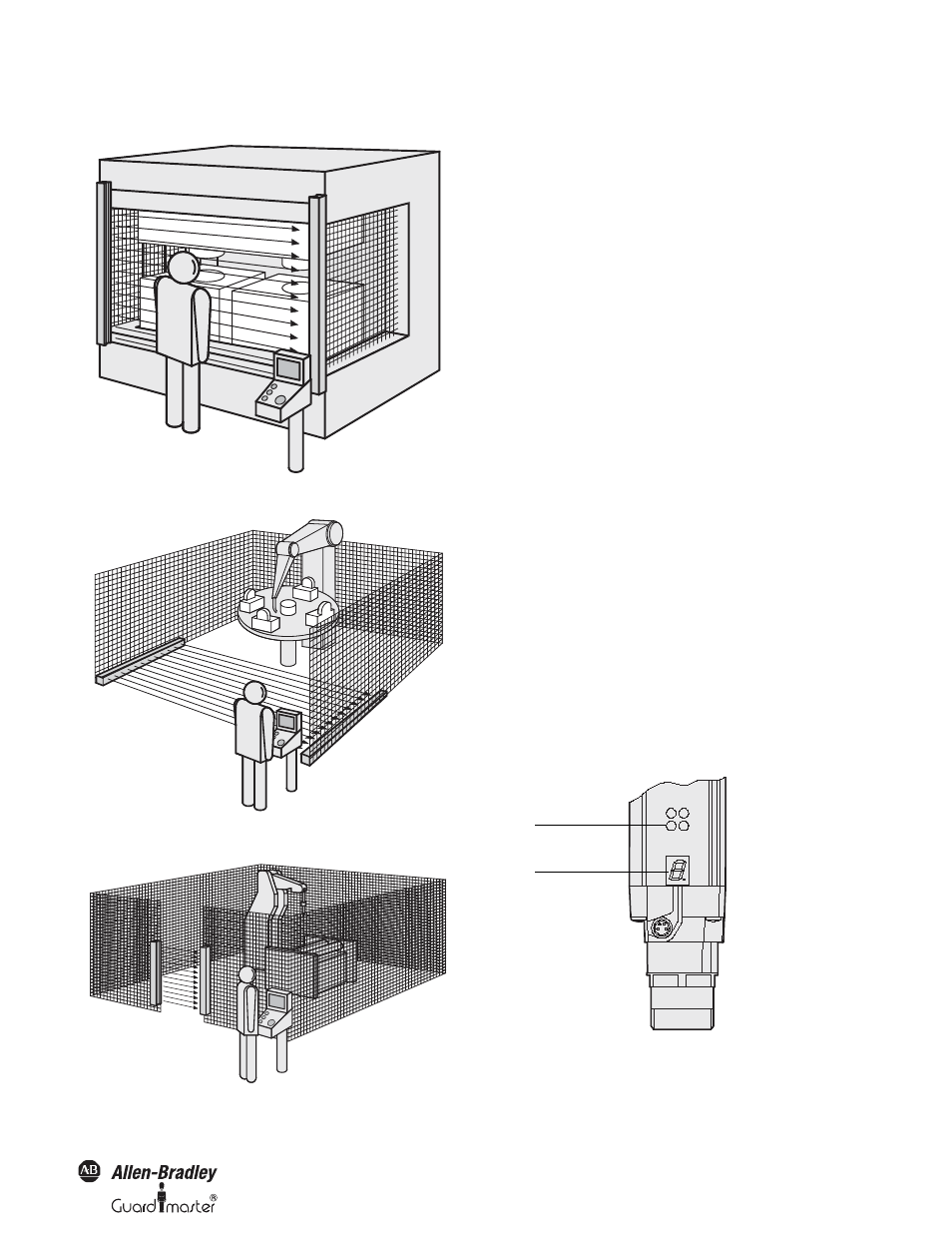

Examples of Range of Use

Figure 2: Hazardous point protection using a SafeShield safety light

curtain

Figure 3: Hazardous area protection using a SafeShield safety light

curtain

Figure 4: Access protection using a SafeShield safety light curtain

The SafeShield safety light curtain operates correctly as a protective

device only if the following conditions are met:

• The control of the machine must be electrical.

• The dangerous state of the machine must be transferable at any

time into a safe state.

• Sender and receiver unit must be so mounted that objects

penetrating the hazardous area are safely identified by the

SafeShield safety light curtain.

• The restart button must be located outside the hazardous area

such that it cannot be operated by a person working inside the

hazardous area. When operating the reset button, the operator

must have full view of the hazardous area.

• The statutory and local rules and regulations must be observed

when installing and using the device.

Status Indicators

The LEDs and the 7-segment displays of the sender and the

receiver signal the operational status of the SafeShield safety light

curtain.

Notes The depiction of numbers on the 7-segment display can be

rotated by 180° with the aid of the SCD software. In this

case the point on the 7-segment display goes out:

• Point visible: The bottom edge of the numbers on the 7-

segment display is pointing towards the configuration

connection.

• Point not visible: The bottom edge of the numbers on

the 7-segment display is pointing towards the LED

display.

Device symbol SafeShield safety light curtain Host

(receiver) or SafeShield safety light curtain Host (sender),

context menu Configuration draft, Edit, option 7-segment

display of the related device.

Status Indicators of the Sender

Figure 5: Status indicators of the sender

!

Yellow

7-segment display