Rockwell Automation 442L SafeShield Safety Light Curtain Hardware User Manual

Page 25

SafeShield Safety Light Curtain Hardware User Manual

25

Sender and receiver can be mounted in two different ways:

• Mounting with swivel mount bracket

• Mounting with side bracket

Mounting with Swivel Mount Bracket

The swivel mount bracket is made of black polyamide PA6. The

bracket is designed such that sender and receiver can still be

accurately aligned even after the bracket has been mounted.

Note

➢ Attach the bolts of the swivel mount bracket with a

torque of between 2.5 and 3Nm. Higher torques can

damage the bracket; lower torques provide inadequate

protection against vibration.

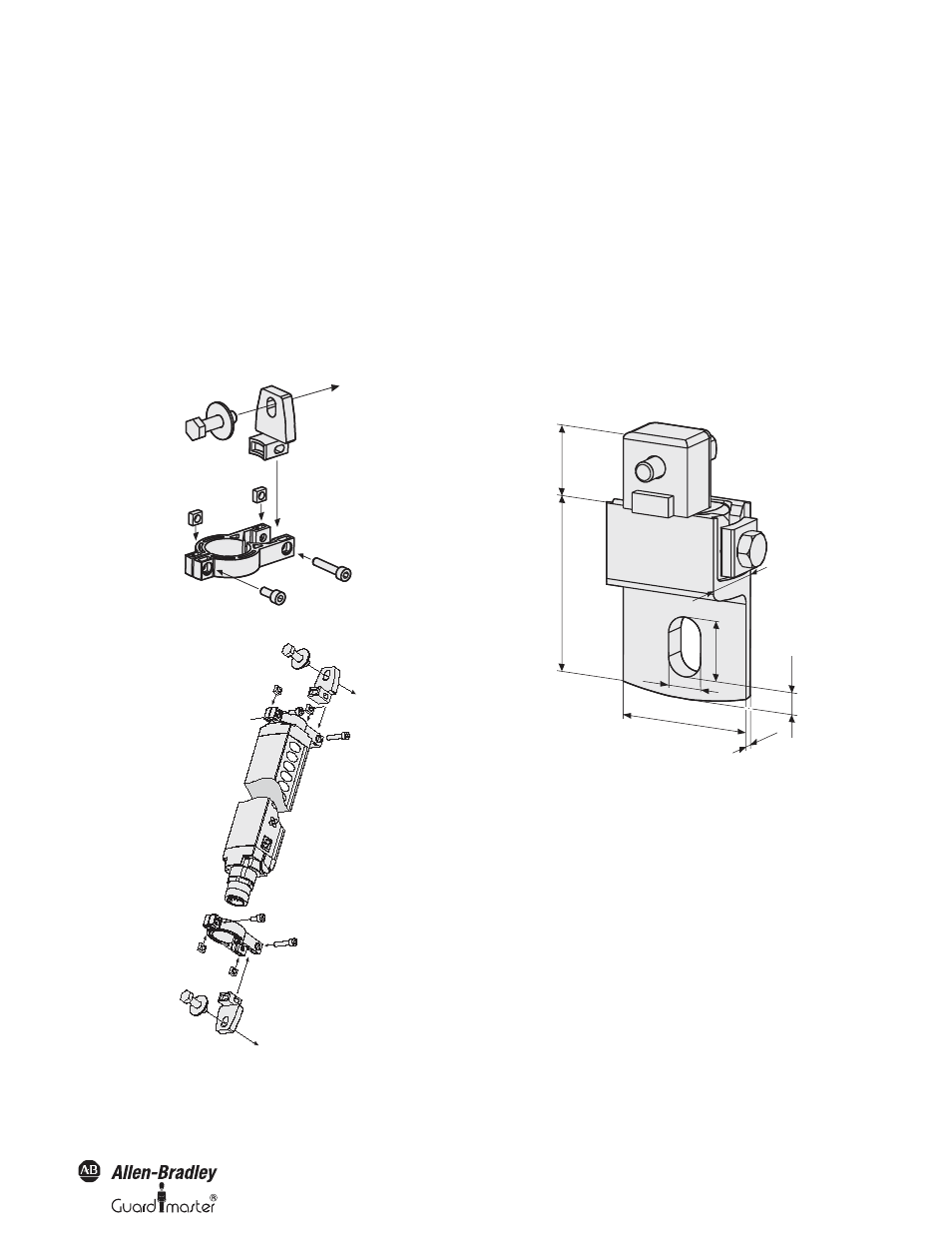

Figure 23: Composition of the swivel mount bracket

Figure 24: Mounting sender and receiver using swivel mount brackets

Note

➢ Mount the bolts marked with ➊ to ➍ on the operator

side of the system to ensure that they remain accessible

after mounting and to allow you to readjust the light

curtain later, if necessary.

➢ If you wish to use the additional front screen (see

“Additional Front Screen (weld shield)” on page 45),

make sure that the curved side of the device remains

accessible after mounting.

Mounting with Side Bracket

The side bracket is made of die cast zinc ZP 0400. It is anodized in

black. The side bracket will be covered by the device after

mounting. But it is only suitable for mounting surfaces lying parallel

to the desired protective field because the alignment of sender and

receiver can only be adjusted by a maximum of

±2.5° after

mounting.

Figure 25: Composition of the side bracket

Note

➢ Attach the bolts of the side bracket with a torque of

between 5 and 6Nm. Higher torques can damage the

bracket; lower torques provide inadequate protection

against vibration.

➢ When mounting the bracket, note the distance and the

position of the sliding nuts as described in the

“Dimensional Drawings” on page 39.