Rockwell Automation 442L SafeShield Safety Light Curtain Hardware User Manual

Page 23

SafeShield Safety Light Curtain Hardware User Manual

23

➢ First, calculate S using the following formula:

S = 2000 × T + 8 × (d – 14) [mm]

Where …

T = Stopping/run-down time of the machine

+ response time of the protective device after light path

interruption [s]

d = Resolution of the light curtain [mm]

S = Safety distance [mm]

The reach/approach speed is already included in the formula.

➢ If the result S is ≤ 500mm, then use the determined value as the

safety distance.

➢ If the result S is > 500mm, then recalculate S as follows:

S = 1600 × T + 8 × (d – 14) [mm]

➢ If the new value S is > 500mm, then use the newly determined

value as the minimum safety distance.

➢ If the new value S is ≤ 500mm, then use 500mm as the safety

distance.

Example:

Stopping/run-down time of the machine = 290 ms

Response time after light path interruption = 30 ms

Resolution of the light curtain = 14mm

T = 290 ms + 30 ms = 320 ms = 0.32 s

S = 2000 Ч 0.32 + 8 Ч (14 – 14) = 640mm

S > 500mm, therefore:

S = 1600 Ч 0.32 + 8 Ч (14 – 14) = 512mm

How to calculate the safety distance D

s

according to ANSI

B11.19-1990 E.4.2.3.3.5 and Code of Federal Regulations,

Volume 29, Part 1910.217 … (h) (9) (v):

Notes The following calculation shows an example calculation of

the safety distance. Depending on the application and the

ambient conditions, a different calculation may be

necessary.

➢ Calculate D

s

using the following formula:

D

s

= H

s

× (T

s

+ T

c

+ T

r

+ T

bm

) + D

pf

Where …

D

s

= The minimum distance in inches (or millimetres) from the

hazardous point to the detection point, plan or zone

H

s

= A parameter in inches/second or millimetres/second,

derived from data on approach speeds of the body or parts

of the body. Often 63 inches/second (1600 millimetres/

second) is used for H

s

.

T

s

= Stopping time of the machine tool measured at the final

control element

T

c

= Response time of the control system

T

r

= Response time of the presence-sensing device and its

interface

T

bm

=Additional response time allowed for brake monitor to

compensate for wear

Notes Any additional time delays must be accounted for in this

calculation.

D

pf

=An additional distance added to the overall safety distance

required. This value is based on intrusion toward the

hazardous point prior to actuation of the electro-sensitive

protective equipment (ESPE). Values range from 0.25 inches

to 48 inches (6 to 1220 millimetres) or more depending on

application.

Example In opto-electronic protection, such as with a

perpendicular safety light curtain applications with

object sensitivity (effective resolution) less than 2.5

inches (64 millimeters), the D

pf

can be approximated

based on the following formula:

D

pf

(inches) = 3.4 × (object sensitivity – 0.276), but not

less than 0.

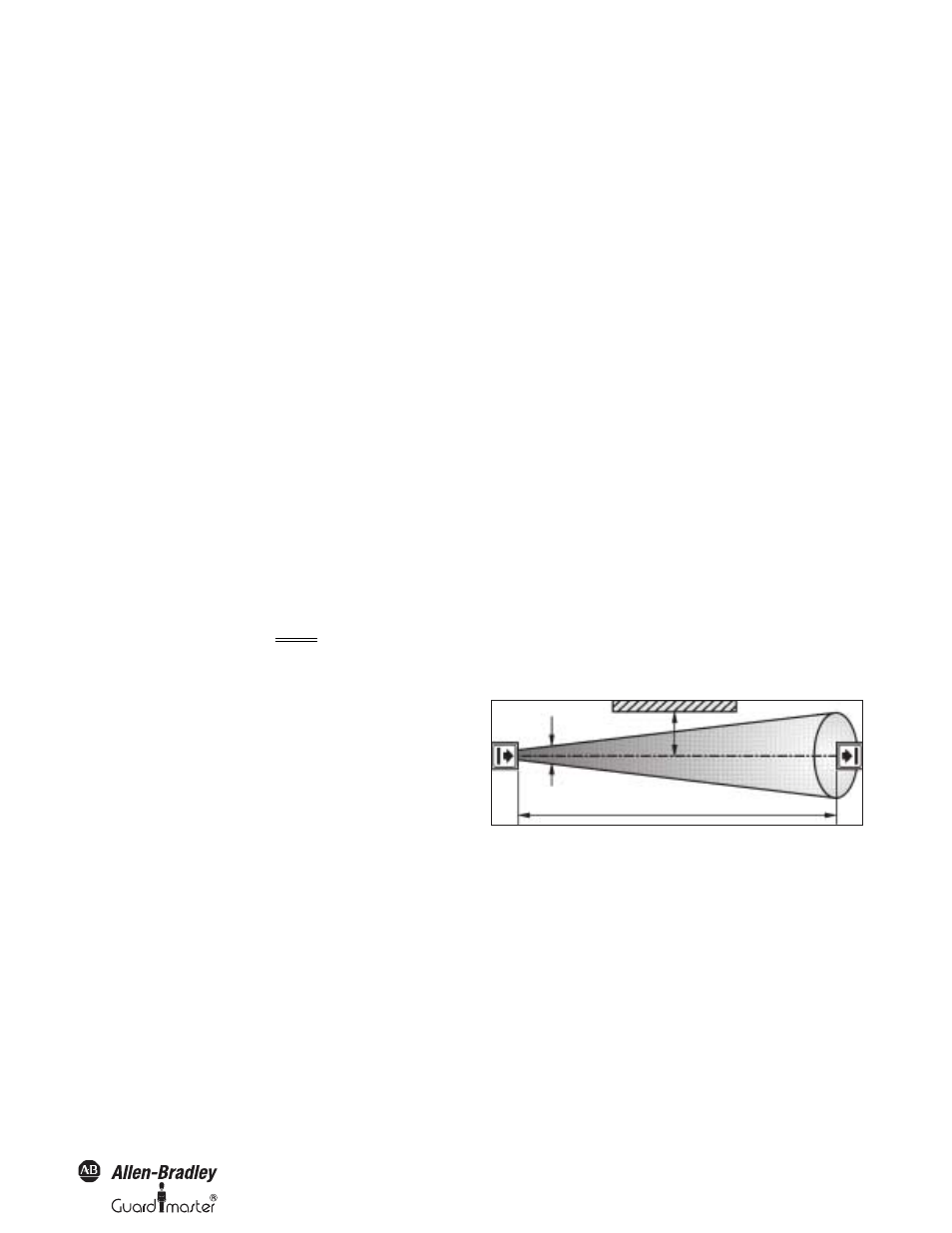

Minimum Distance to Reflective Surfaces

The light beams from the sender may be deflected by reflective

surfaces. This can result in failure to identify an object.

All reflective surfaces and objects (e.g. material bins) must

therefore be located at a minimum distance a from the protective

field of the system. The minimum distance (a) depends on the

distance (D) between sender and receiver.

Figure 20: Minimum distance from reflective surfaces

Notes The field of view of the sender and receiver optics is

identical.

How to determine the minimum distance from reflective

surfaces:

➢ Determine the distance (D) [m] sender-receiver.

➢ Read the minimum distance (a) [mm] from the graph:

Reflective surface

Minimum distance (a)

Field of view

Distance (D) sender-receiver