Ventilated enclosures, Non-ventilated enclosures – Rockwell Automation 150 USE MN/SMC DIALOG + CONTROLLER User Manual

Page 29

Installation

2-3

Ventilated Enclosures

For Type 1 (IP42) enclosures, the following guidelines are

recommended to limit the maximum controller ambient temperature.

There should be a clearance of at least six inches (15 cm) above and

below the controller. This area allows air to flow through the

heatsink. Ventilation openings are required above and below this air

space.

The ventilation outlet should be placed at least six inches (15 cm)

above the controller with the ventilation inlet placed near the bottom

of the enclosure. A filter is required to prevent contaminants from

entering the enclosure.

Use the table below to determine the minimum ventilation openings

and fan/blower requirements.

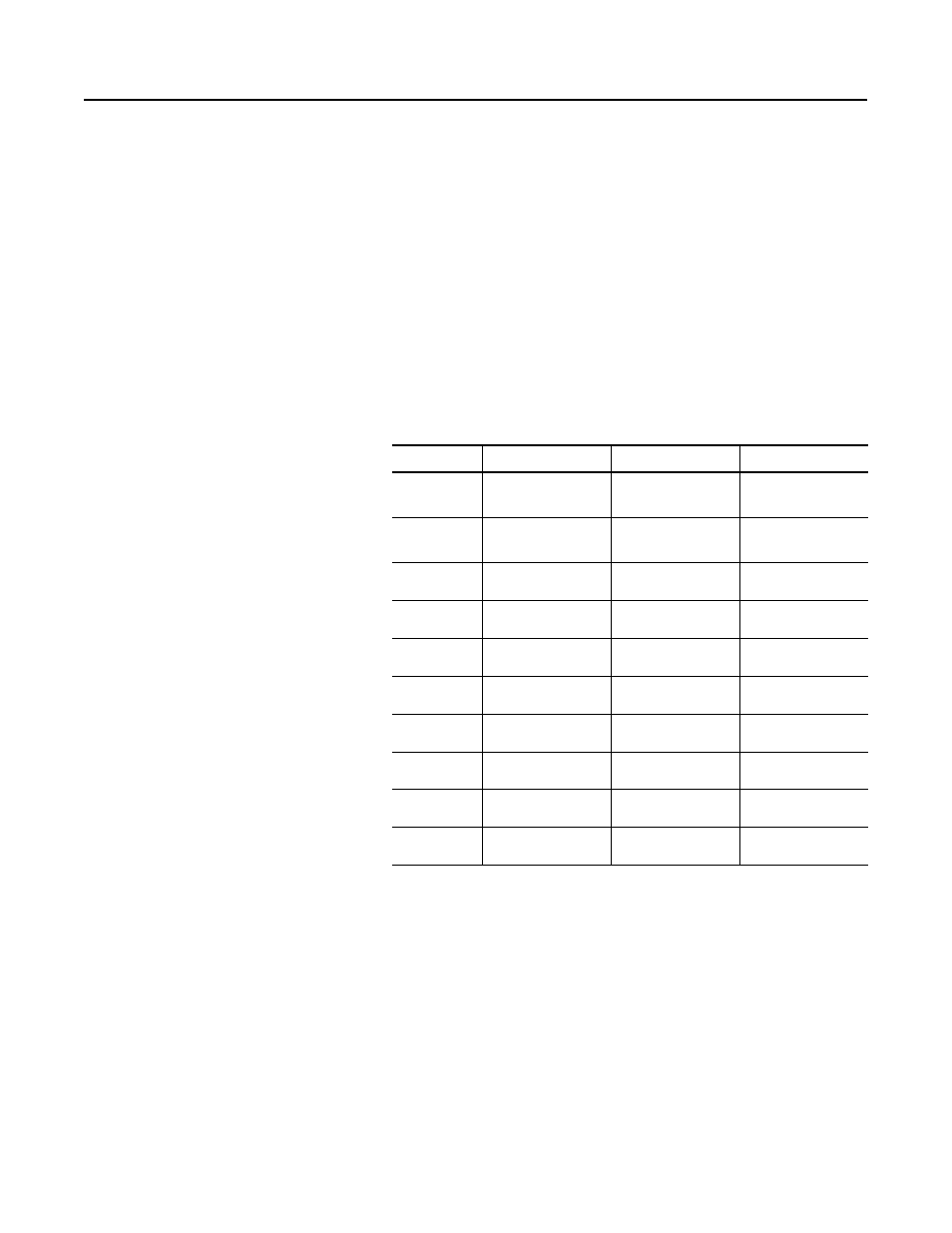

Table 2.B Minimum Ventilation Openings

①

Cutout size assumes 50% blockage (filters, louvers, etc.)

②

Cutout size is the same as required for the particular fan or blower being used.

③

Dimensions are in centimeters (inches in parentheses).

Non-ventilated Enclosures

For Type 12 (IP54) or non-ventilated enclosures, it is recommended

that a bypass contactor be used. This will allow the SMC Dialog Plus

controller to bring the motor up-to-speed. After the controller is up to

full voltage, it is bypassed. Note that the Energy Saver, Phase

Rebalance, some metering functions, and some protective features of

the controller may no longer be available. See Figure 3.17 on page 3-

13 for this configuration.

SMC Rating

Top Cutout

①③

Bottom Cutout

①③

Fan Size

①

24–54A

65 cm

2

(10 in

2

)

65 cm

2

(10 in

2

)

110 CFM

97 and 135A

233 cm

2

(36 in

2

)

233 cm

2

(36 in

2

)

110 CFM

180A

13 Ч 51

(5 Ч 20)

②

100 CFM

240A

13 Ч 51

(5 Ч 20)

②

250 CFM

360A

13 Ч 51

(5 Ч 20)

②

(2) 250 CFM

500A

13 Ч 41

(5 Ч 16)

②

275 CFM

650A

②

13 Ч 76

(5 Ч 30)

(3) 240 CFM

720A

②

13 Ч 76

(5 Ч 30)

(3) 240 CFM

850A

②

13 Ч 76

(5 Ч 30)

(3) 240 CFM

1000A

②

13 Ч 76

(5 Ч 30)

(3) 240 CFM