Jumper locations and settings – Rockwell Automation 20G PowerFlex 750-Series Power Jumpers User Manual

Page 5

Rockwell Automation Publication 750-IN011E-EN-P - February 2014

5

PowerFlex 750-Series Power Jumpers

Jumper Locations and

Settings

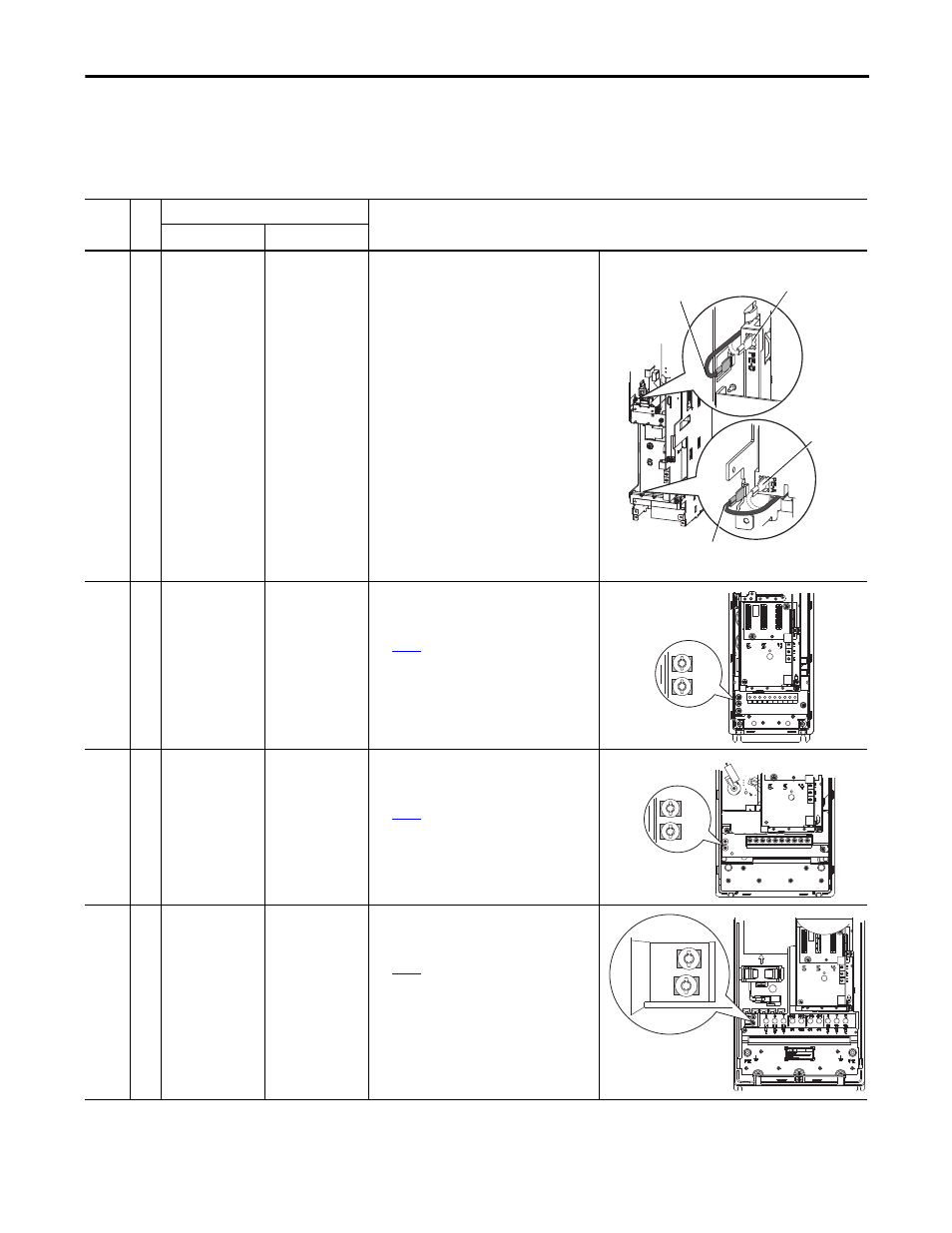

The following pages show jumper locations and settings.

Frame

Vo

lt

ag

e

Code

Factory Default Jumper Settings

Power Source Type

Catalog Code “A”

Catalog Code “J”

1

C

D

PE-A jumper wire

connected to ground.

PE-B jumper wire

insulated/

disconnected from

ground.

PE-A jumper wire

and PE-B jumper

wire connected to

ground.

Solid Ground

Connect the MOV/Input Filter Cap jumper wire (PE-

A) and the CM Cap jumper wire (PE-B) to ground.

Non-Solid Ground

Insulate the MOV/Input Filter Cap jumper wire (PE-

A) and the CM Cap jumper wire (PE-B) from

ground.

2

C

D

PE-A Installed

PE-B Not Installed

PE-A Installed

PE-B Installed

Solid Ground

Install jumper screws at “PE-A” (MOV/Input Filter

Cap) and “PE-B” (CM Cap).

See

for recommended torque.

Non-Solid Ground

Remove both jumper screws.

3

C

D

E

PE-A Installed

PE-B Not Installed

PE-A Installed

PE-B Installed

Solid Ground

Install jumper screws at “PE-A” (MOV/Input Filter

Cap) and “PE-B” (CM Cap).

See

for recommended torque.

Non-Solid Ground

Remove both jumper screws.

4

C

D

E

PE-A Installed

PE-B Not Installed

PE-A Installed

PE-B Installed

Solid Ground

Install Jumper screws at “PE-A” (MOV/Input Filter

Cap) and “PE-B” (CM Cap).

See

for recommended torque.

Non-Solid Ground

Remove both jumper screws.

PE-A

PE-B

Insulated

Connected

Insulated

Connected

PE-B

PE-A

PE-B

PE-A

PE-B

PE-A